Continuous air barrier systems control air, moisture, and heat transfer within the building envelope in order to protect a structure's long-term integrity to help create a healthy indoor environment. Examples of air barriers include fluid-applied, self-adhered/peel-and-stick membranes, mechanically fastened materials, and rigid sheathings.

Regardless of the type of air barrier system you choose, its design and assembly, in relation to the building envelope components, should address all types of air movement:

- Infiltration - unconditioned outside air flowing into the conditioned interior spaces of a building

- Intrusion - Intrusion is not technically air leakage. It happens when air moves from the building's conditioned spaces into the wall or roofing system, leading to condensation and damaging effects of mold. A self-adhered vapor retarder barrier as a continuous air barrier will minimize air intrusion.

- Exfiltration - conditioned inside air flowing to the outside of the building

Contact our Polyguard architectural professionals for help choosing the proper air barrier for your building project. Keep reading to learn more about examples of air barriers.

Choosing a Code-Compliant Air Barrier

The type of continuous air barrier you apply to achieve code compliance depends on the environment, building use and type, and wall design. Contractors can use numerous materials or continuous coating or film as an air barrier as long as it includes the following features:

- Impermeable to airflow or meet permeability requirements

- The ASTM E2178 demands that an air barrier's air permeance not surpass 0.02 L/(s·m²) at a pressure difference of 75 Pa (0.004 cfm ft2 at a pressure difference of 1.56 lb ft2). Air permeance indicates the quantity of air that flows through a material. In comparison, air leakage flows through holes and cracks.

- Continuous installation over the entire building enclosure, with all penetrations and terminations sealed completely

- The ability to withstand forces, like dimensional changes or stress, that act on them during and after construction

- The durability to tolerate ultraviolet light, precipitation, freezing, and thawing to ensure its integrity over the expected lifetime of the building

In addition, you must follow the manufacturer's instructions and properly integrate the air barrier system and building enclosure components to stop air leakage at the joints between the penetrations and components.

Air Barrier Code Requirements

The International Residential Code (IRC) and the International Building Code (IBC) provide code requirements for residential and commercial buildings.

Residential Buildings

The 2021 IRC (Table R402.4.1.1) mandates sealing breaks in its joints and applying a continuous air barrier in a building envelope. IRCs cover detached one-and-two residential buildings and townhouses no higher than three levels above the grade plane. They should also have a separate means of egress with accessory structures (e.g., barns, garages, carports, playhouses, sheds, private greenhouses) no higher than three stories above the grade plane.

Commercial Buildings

The 2021 IBC, Section C402.5.1, mandates a continuous air barrier around the building envelope for commercial buildings (except climate zone 2B). Additionally, builders can place air barriers inside or outside the building envelope, within the envelope assemblies, or any combination thereof. The air barrier must meet the requirements of Sections C402.5.1.1 and C402.5.1.2.

The IBCs apply to all structures that do not conform to the required provisions of the IRC.

Types of Air Barriers

Builders can choose between four types of air barrier materials: fluid-applied, self-adhered/peel-and-stick, mechanically fastened materials, and rigid sheathings.

Fluid-Applied Air Barriers

Fluid-applied air barriers create a monolithic coating that bonds to exterior sheathing without fasteners. Builders can spray, roll, or trowel fluid-applied barriers into a substrate; however, they require skilled installers and dry conditions to ensure the product's performance. Fluid-applied air barriers provide several advantages that save both money and time, and help protect the integrity and health of a building or home:

Air Barrier: An air barrier stops air leakage, lowers energy costs and condensation, and enhances occupant comfort.

Wind Barrier: It provides structural and full adherence, which creates stability and rigidity against strong wind events.

Moisture Barrier: Fluid-applied air barriers create a seamless moisture barrier by lessening installation errors that can cause lap joints, holes, and tears.

Durable: It will not lose effectiveness or tear when exposed to outside elements before, during, and after construction.

Flexible and Quick Application:

Fluid-applied air barriers efficiently adhere to and waterproof many wall conditions and penetrations (like tiles, brick, or electrical conduits), detail wall openings, fasteners, repair locations, and conform to uneven substrates.

Fluid-applied air barriers quickly adapt to complex substrate geometry.

A qualified installer can quickly roll or spray-apply the fluid-applied air barrier onto the wall substrate.

Fluid-applied air barriers do not need a primer.

Safe: Water-based fluid-applied air barriers are safe to use, VOC compliant, and easy to clean up.

Rainwater Barrier: A rainwater barrier allows for pressure-equalized or pressure-moderated wall design, which reduces the risk of rainwater penetration through the wall system.

Low Maintenance: It protects the sheathing and rough openings from weather damage during and after construction, which minimizes repair or replacement costs.

Polyguard Fluid-Applied Air Barriers

Polyguard is a permeable and impermeable fluid-applied air barrier designed for application to most substrates: Airlok® Flex® VP and Stretch Flex.

Polyguard Airlok® Flex® Fluid-Applied Air Barriers

Water- and acrylic-based, permeable, single-component, cold fluid-applied Polyguard Airlok® Flex® VP above-grade, elastomeric membrane stops air and moisture infiltration while also allowing water vapor to escape.

Builders can apply Airlok® Flex® VP on:

- Concrete

- Concrete Masonry Units (CMU)

- Glass and Paper

- Foil-Faced Sheathing

Plywood, Oriented Strand Board (OSB), and Rigid Insulation in the cavity

Easy-to-apply, single-component Airlok® Flex® VP Fluid-Applied Air Barrier products provide several benefits and features.

Benefits and Features of Airlok® Flex® VP

- Builders can use UV-resistant (up to one year) Airlok® Flex® VP on sun-exposed and unexposed exterior walls

- Temperature-resistant Airlok® Flex® VP allows for applications between 40°F (4.4°C) and 120°F (48.8°C)

- Airlok® Flex® VP forms a tough, continuous bonded elastomeric barrier that protects against air exfiltration and infiltration in order to lower energy loss

- Can easily apply (in one or two coats) Airlok® Flex® products with spray equipment or roller, and detail before or after application

- NFPA 285 compliant

- Safe, with a VOC content of 50 g/L

- Permeable to 10 perms

- 32 wet /16 dry mils (50 ft2 / gal theoretical coverage rate)

Polyguard Stretch Flex

Builders can spray Polyguard, above-grade, vapor-impermeable Stretch Flex in temperatures down to -20°F (-28.89°C). This feature allows for design flexibility and cost savings because it eliminates the need to tent the building in cold weather conditions.

Builders can use Stretch Flex in cold climates to stop the infiltration and exfiltration of air and moisture on:

- Exterior-Grade Gypsum Sheathing

- Concrete

- Concrete Masonry Walls (CMU)

- Plywood

- Oriented Strand Board (OSB)

Benefits and Features of Polyguard Stretch Flex

- A patented, elastomeric, thermoplastic, synthetic rubber coating, waterproofing concrete sealer

- Non-permeable (0.216 perms)

- Solvent-based

- Rubber coating with VOC content of 525 g/L

- Application temperature ranging from -20°F (-29° C) to 120°F (48.8°C)

- 40 mil wet / 20 dry mils (40 ft2/gal theoretical coverage rate)

- Six months of UV resistance

- NFPA 285 compliant

Self-Adhered/Peel-and-Stick Membranes

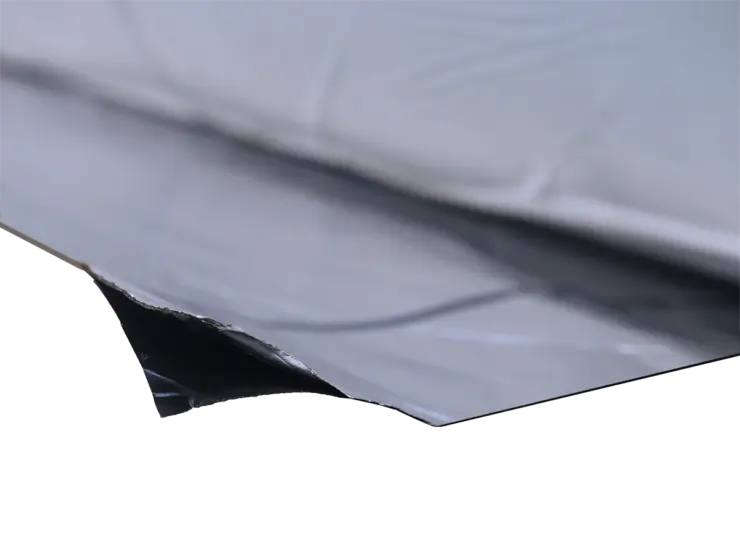

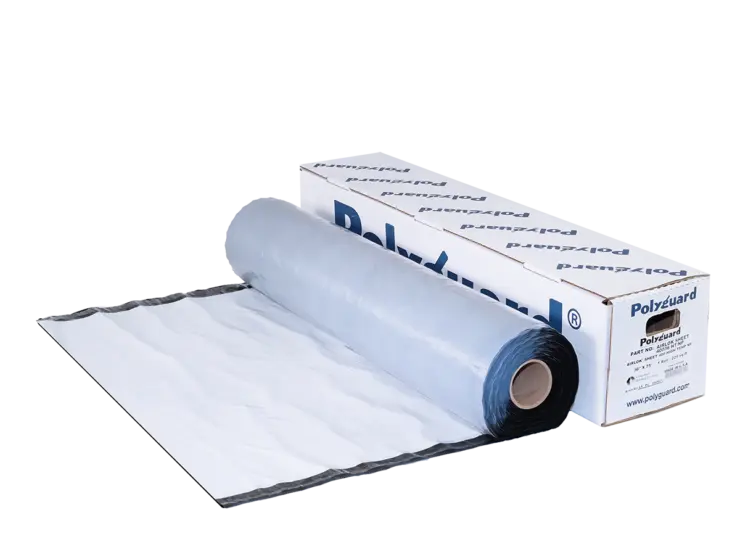

Peel-and-stick, self-adhered membranes or films are pressure- or heat-applied and are typically impermeable to water vapor. Self-adhered air barrier sheets typically come in rolls that have a rubber-modified asphaltic "adhesive" membrane with a polyethylene laminated film on the exterior side and a release film underneath, which creates a monolithic, waterproof, airtight layer. Self-adhering peel-and-stick barriers come in various seasonal grades to allow for application under different ambient temperatures.

Builders must carefully install a peel-and-stick membrane and seal all penetrations to stop water infiltration and accumulation in the wall system, which can lead to structurally damaging mold. In addition, adequate adhesions require a clean and primed (required in cold conditions) substrate.

Polyguard Self-Adhered/Peel-and-Stick Membranes

Polyguard offers five self-adhesive, non-permeable membranes. Each comes with similarly specified complementary flashing products. We also offer a series of fluid-applied flashing and detail products.

Airlok® Sheet200 BU/NP

Self-adhesive, non-permeable, 28-mil, 100-foot laminated butyl Airlok® Sheet 200 BU/NP sheet membrane bonds to a cross-laminated polyethylene sheet designed for moisture and air applications.

Builders can use Airlok® Sheet 200 BU/NP as a field membrane, window flashing, and through-wall flashing for assemblies like brick facades.

Benefits and Features of Airlok® Sheet 200 BU/NP

- Creates a non-permeable product that can accommodate various dynamic movements and changes in plane

- Provides superior resistance to air leakage and vapor diffusion

- Excellent bonding to a substrate in extreme hot and cold conditions

- Offers an in-service temperature range of 20°F (-7° C) to 240°F (116°C)

- 28-mil butyl compound sheet for field membranes works well as window and through-wall flashings

- High puncture resistance protects against damage on the job site

- Does not require field priming

- Sold in 6, 9, 12, 18, and 24-inch widths, 100 linear foot rolls

- Under most weather conditions, you do not need to prime field-applied 36-inch wide membranes

- Can field cut to meet the specific needs of a project

- Allows for 60-day UV exposure

Note: Do not use Airlok® Sheet 400 NP in areas permanently exposed to sunlight. It is important to know that it also has limited NFPA 285 assembly.

Airlok® Sheet UV 200 BU/NP

Non-permeable, self-adhesive, 28-mil Airlok® Sheet UV 200 BU/NP consists of a foil/polyscrim film laminated to a layer of butyl designed for moisture and air applications. Airlok® Sheet UV 200 BU/NP offers one-year UV exposure.

Builders can use Airlok® Sheet UV 200 BU / NP as field membranes and window flashings for high UV exposure assemblies due to extended construction schedules.

Benefits and Features of Airlok® Sheet UV 200 BU/NP

- Non-permeable formulation allows for one-year UV exposure

- Offers an in-service temperature range of 20°F (-7° C) to 240°F (116°C)

- It comes in 6, 9, and 12-inch width rolls of 100 linear feet

- Excellent bonding to the substrate in extreme hot and cold conditions

- Does not require field priming of 36-inch membranes in most conditions

- Offers excellent resistance to air leakage and vapor diffusion

- High puncture resistance that protects against damage on the job site

NOTE: Do not use Airlok® Sheet UV 200 BU / NP for through-wall flashings in masonry facades.

Airlok® Sheet 400 HT/NP

Self-adhesive, non-permeable, 40-mil, 36-inch x 75-foot laminated, modified asphalt Airlok® Sheet 400 HT/NP sheet membrane bonds to a cross-laminated polyethylene sheet designed for air and moisture applications.

Builders can use Airlok® Sheet 400 HT/NP for high-temperature field membrane, window flashing, and through-wall flashing for assemblies like metal cladding and coping caps.

Benefits and Features of Airlok® Sheet 400 HT/NP

- Allows for high-heat applications like metal cladding and copings

- Rubberized asphalt properties allow for self-sealing around fasteners, sealing of laps, and adhesion, eliminating membrane blow-off and tears before exterior wall finish installation

- Flexible in order to accommodate various dynamic movements and changes in the plane

- Offers excellent resistance to air leakage and vapor diffusion

- Once installed and covered with cladding, the membrane will not decay from mold or mildew

- High puncture resistance protects against damage on the job site

- Can field cut to meet the specific needs of a project

- Temperature resistance between 40°F (5°C) to 260°F (127°C)

- Provides a 60-day UV exposure

NOTE: Do not apply Airlok® Sheet 400 NP in areas permanently exposed to sunlight, which can impair the barrier’s integrity.

Airlok® Sheet 400 NP

Self-adhesive, non-permeable, modified-asphalt, 40-mil Airlok® Sheet 400 NP sheet membranes bond to a cross-laminated polyethylene sheet, which makes it suitable for moisture and air applications with a 60-day UV exposure.

Builders can use Airlok® Sheet 400 NP field membrane, window flashing, and through-wall flashing for assemblies like brick facades.

Benefits and Features of Airlok® Sheet 400 NP

- It comes in 6, 9, 12, 18, 24, and 36-inch width rolls 75 linear feet long

- Offers excellent resistance to air leakage and vapor diffusion

- Provides high puncture resistance to protect from damage on the job site

- Can field cut to meet the specific needs of a project

- Applying temperatures of 25°F (-4°C) and higher

- Provides a robust seam with selvedge (selvages) edges and zip strips

- Allows for 60-day UV exposure

NOTE: Airlok® Sheet 400 NP has a maximum in-service temperature of 160°F (71°C) and limited NFPA 285 assembly.

Airlok® Sheet UV Ultra 400 NP

Self-adhesive, non-permeable, 40-mil Airlok® Sheet UV Ultra 400 composite sheets and complementary flashings consist of a durable foil facing laminated to a rubberized asphalt layer, designed to withstand two years of UV exposure.

Builders can use Airlok® Sheet UV Ultra 400 as field membranes and window flashings for high UV exposure assemblies due to prolonged construction schedules.

Benefits and Features of Airlok® Sheet UV Ultra 400

- The rubberized asphalt allows for sealing of laps, self-sealing around fasteners, and adhesion to the substrate at ambient temperatures higher than 40°F (4.4°C)

- Non-permeable Airlok® UV Ultra 400 NP allows for two years of UV exposure

- NFPA 285 assembly

- It comes in 6, 9, 12, and 36-inch width rolls 75 feet long

- Offers excellent resistance to air leakage and vapor diffusion

- Provides high puncture resistance to protect from damage on the job site

- You can field cut to meet the specific needs of a project

- Offers cut sizes for flashing applications to complement the sheet application

NOTE: Airlok® Sheet UV Ultra 400 has a maximum in-service temperature of 160°F (71°C). Do not use it on through-wall flashings in masonry facades.

Mechanically Fastened Materials

Mechanically attached air barriers fasten the sheathing by stapling or using a cap fastener, which allows for installation in cold and wet climates. However, mechanically attached air barriers may leak at the nail fasteners.

Rigid Sheathing

Builders can apply rigid sheathing, including extruded polystyrene, faced polyurethane foam boards, and gypsum, as an exterior air barrier. To ensure airtightness, you must thoroughly seal the rigid sheathing by:

- Covering the seams or butt joint with durable sealants, specialized tapes, or membranes,

- Sealing all penetrations, and

- In addition, rigid sheathings require proper integration with the water-resistive layer to stop moisture accumulation behind the assembly.

Air Barrier Examples and Which Is Best for Your Project

Examples of air barriers include fluid-applied, self-adhered/peel-and-stick membranes, mechanically fastened materials, and rigid sheathings. Regardless of the type of air barrier system, it must be continuous across the building envelope to effectively control air, moisture, and heat transfer within the building envelope - vital to protecting a structure's long-term integrity and helping create a healthy indoor environment.

Polyguard air barrier systems offer builders numerous air barriers to best fit the conditions and goals of their projects. Our fluid-applied and peel-and-stick membranes, when properly installed, will contribute significantly to creating a tight building envelope.

Contact our Polyguard architectural professionals for help choosing the proper air barrier for your building project and the benefits of applying Polyguard’s fluid and self-adhered air barriers.