Concrete bridge decks must resist environmental conditions, wear and tear, and provide consistent, long-term traction and ride quality. A deck's constant exposure to extreme weather and heavy traffic requires careful design and sound construction practices to ensure a safe, long-lasting bridge. Corrosion poses a significant threat to a bridge deck's integrity; therefore, the design should include applying a concrete bridge deck sealer.

Concrete bridge deck sealing with sufficient waterproofing, along with surface overlaying, will reduce the rate of chloride attack and corrosion on the reinforcing steel to help extend the deck's service life and lessen its long-term maintenance and repair expenses to limit traffic interruptions and to avoid the potential costs of demolition and rebuilding.

Use Bridge Deck Sealing to Avoid the Corrosion of Concrete Decks

Corrosion of the deck's reinforcing steel contributes significantly to deterioration. Corrosion occurs when water and chlorides penetrate the concrete through small cracks and attack the steel which causes it to corrode. The steel corrosion by-products expand and cause deck delaminations, spalling, scaling, and cracking. Using de-icing salts to melt snow escalates the corrosion rate in bridge decks.

Maintaining a concrete bridge deck's integrity depends significantly on implementing materials and methods that prevent water and chlorides from reaching and corroding the reinforcing steel in the bridge deck:

- Sealing and waterproofing the bridge deck and its cracks

- Overlaying the surface with dense materials, like asphalt

Note: Always consult an engineer before applying an overlay over an existing bridge to ensure the bridge can handle the extra load

- Cathodic protection stops the corrosion of the steel from progressing if chlorides penetrate due to damage to the deck

In addition, the following construction and maintenance tips can help preserve the integrity of the bridge and prevent corrosion:

- Washing and cleaning the deck

- Proper curing procedures that prevent excessive shrinkage cracking

- Concrete with appropriate water-cement ratios

- Designing and building the bridge deck with:

- Corrosion-resistant reinforcing steel

- Waterproofing methods, including good drainage

- Air-entrained concrete in areas subject to freezing

Bridge Deck Sealing and Waterproofing

Bridge decks receive the brunt of environmental attacks from rain, snow, ice, etc., as well as mechanical wear from continual traffic. Consequently, bridge decks require more waterproofing protection that is provided by traditional penetrating sealers.

Penetrating Sealers

Applying penetrating sealers to existing, above-ground concrete surfaces reduces the concrete's permeability by ten times. The concrete's permeability most significantly affects the rate of rebar corrosion deterioration, alkali-aggregate reaction, carbonation, and the effects of freeze-thaw cycles.

Concrete sealers contain chemical water-repellent agents that are sprayed on above-ground concrete surfaces. The sealant penetrates the concrete and micro and hairline cracks to create a protective barrier on the concrete surface. Extreme weather conditions and traffic can damage the penetrating sealer’s integrity. To maintain the effectiveness of the concrete sealers, you must reapply every three to four years.

Bridge Deck Waterproofing Membranes

Most bridge decks experience heavy and constant traffic and severe attacks from water, chlorides, acid rain, de-icing salts, and freeze-thaw cycles. Therefore, the bridge deck's structural integrity and safety depend on protecting and waterproofing its concrete and reinforced steel components from the environment and traffic.

Waterproofing membranes applied to new and existing bridge decks provide the following benefits:

- Prevents defrosting salt from passing through concrete bridge cracks that will cause reinforcement corrosion. Chloride and moisture will deteriorate concrete bridge decks, cause scaling, cracking, and spalling, and eventually erode the steel bars within the concrete.

- Protects the bridge deck if dangerous chemicals leak from tanker traffic, which will deteriorate the concrete

- Prevents water from penetrating through bridge cracks, which causes freeze-thaw damage to the bridge deck. In addition, oxygen and moisture will oxidize and corrode the bridge's steel parts, which causes further spalls and cracks that worsen corrosion.

Polyguard Bridge Deck Waterproofing Membranes

Polyguard bridge deck waterproofing membranes protect the long-term integrity of the bridge deck, increase its lifespan, lower maintenance, repair, and replacement costs, and limit traffic interruption.

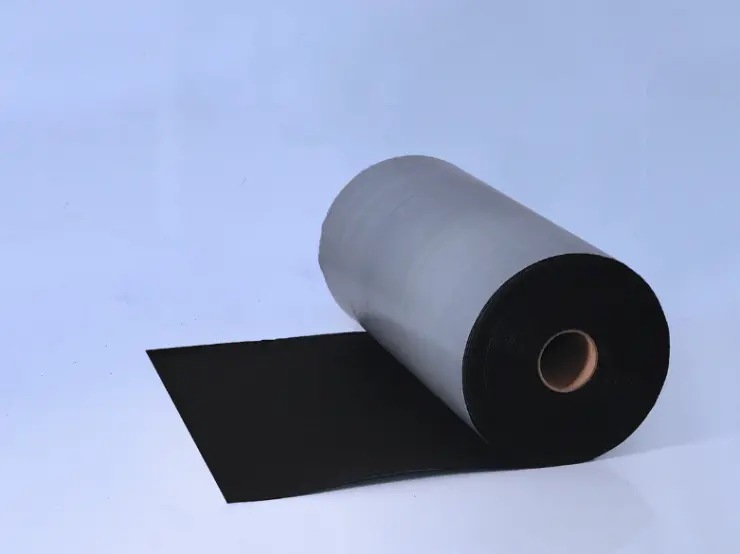

Most states' Department of Transportation recognize using Polyguard Pavement membranes to protect bridge decks from moisture infiltration. Our membranes comprise rubberized asphalt waterproofing adhesive laminated to polypropylene fabric backings. A disposable silicone-treated release sheet is attached to the laminated membrane to stop the membrane from sticking to itself while in the roll.

Note: Woven polypropylene backings may shrink at 300°F (148.89°C). Therefore, contact Polyguard for technical advice for Superpacer overlay that requires paving temperatures greater than 300°F (148.89°C).

Polyguard's waterproofing membranes and companion products aim to protect the bridge deck's long-term integrity

Long-Lasting and Tough 665 Waterproofing Membrane

Containing a rubberized asphalt laminate, 665 Waterproofing Membrane has woven solid polypropylene mesh backing that is both durable and self-sealing.

650 RC Liquid Adhesive

Polyguard recommends applying 650 RC Liquid Adhesive before the membrane to concrete bridge decks.

Applying solvent-based Polyguard 650 RC Liquid Adhesive asphaltic primer below waterproofing membranes enhances the bond between the membrane and the pavement. Easy-to-apply, 650 RC Liquid Adhesive meets the requirements of ASTM D-41.

NW75 Bridge Deck Membrane

Because Polyguard NW75 is a non-woven polypropylene fabric laminated to a rubberized asphalt waterproofing sealant adhesive, it reduces cracking and corrosion while the waterproofing seal stops water infiltration.

Sealing and Waterproofing Bridge Decks with Polyguard Bridge Deck Waterproofing Membranes

The importance of bridge deck sealing cannot be echoed enough. Without proper protection, bridge decks are prone to consistent repairs or maintenance request.

However, by using high-quality bridge deck waterproofing membranes, it’s possible to minimize—and perhaps eliminate most—waters and chlorides from contacting the concrete of a new or existing bridge deck. As a result, the bridge decks and road surfaces last much longer because of the waterproofing membranes.

To learn more about waterproofing roads or waterproofing bridge decks, including the proper use of bridge deck sealing and waterproofing membranes, contact the professionals at Polyguard today!