A waterproof membrane for roof applications provides a barrier that protects structures from water infiltration and subsequent damage. Flat and low-slope roofs, where water drainage is less efficient, particularly benefit from these systems.

This guide covers the different types, uses, and cutting-edge advancements in roof waterproofing membranes to help you make informed decisions for your projects.

Understanding Roof Waterproofing Membranes

Roof waterproofing membranes are continuous materials applied to roofing surfaces to prevent water penetration. A waterproof roof membrane acts as a shield, mitigating risks of structural damage, mold, and compromised insulation. These membranes are engineered to suit various environmental conditions, offering durable solutions for flat and sloped roofs alike.

For flat roofs, where pooling water is a common concern, a properly installed waterproof membrane for roof systems ensures longevity and reduces maintenance. These features are not just about safeguarding the structure but also optimizing energy efficiency and minimizing repair costs over time.

Exploring Different Types of Roof Waterproofing Membranes

Selecting the right type of waterproof roofing membrane requires understanding the unique properties of each option. Below are the most common types used in modern construction.

EPDM (Ethylene Propylene Diene Monomer)

EPDM is a synthetic rubber membrane well-known for its flexibility and resistance to UV damage.

- Advantages:

- Exceptional performance under extreme weather conditions.

- Minimal maintenance requirements over its 30-year lifespan.

- Cost-effective for both residential and commercial applications.

- Applications:

- Ideal for flat or low-slope roofs in areas with high sun exposure or temperature variations.

TPO (Thermoplastic Polyolefin)

TPO membranes are valued for their energy efficiency and reflective surfaces.

- Advantages:

- Heat-welded seams provide excellent waterproofing.

- Reflective properties reduce cooling costs, making them a sustainable choice.

- Resistant to dirt and debris, ensuring longer performance without frequent cleaning.

- Applications:

- Perfect for commercial buildings prioritizing energy efficiency, such as office complexes or warehouses.

PVC (Polyvinyl Chloride)

PVC membranes are renowned for chemical resistance and flame-retardant properties.

- Advantages:

- Reliable under industrial conditions where pollutants or chemicals are present.

- Heat-welded seams ensure long-lasting waterproofing.

- High durability, even under fluctuating temperatures.

- Applications:

- Common in industrial buildings and facilities like labs or restaurants.

Modified Bitumen

A popular choice for its versatility, modified bitumen combines traditional asphalt with modern polymers.

- Advantages:

- Multiple application methods, including self-adhered systems.

- High tensile strength makes it suitable for roofs subject to heavy loads or foot traffic.

- Decades of proven performance in the roofing industry.

- Applications:

- Widely used in residential and commercial low-slope roofs.

Liquid-Applied Membranes

Liquid-applied membranes cure into seamless layers, making them highly adaptable to complex roof geometries.

- Advantages:

- Ideal for roofs with penetrations or intricate designs.

- Seamless application minimizes potential leak points.

- Excellent for retrofit projects, as they adhere well to existing roofing materials.

- Applications:

- Perfect for irregularly shaped roofs or when extending the life of an existing roof.

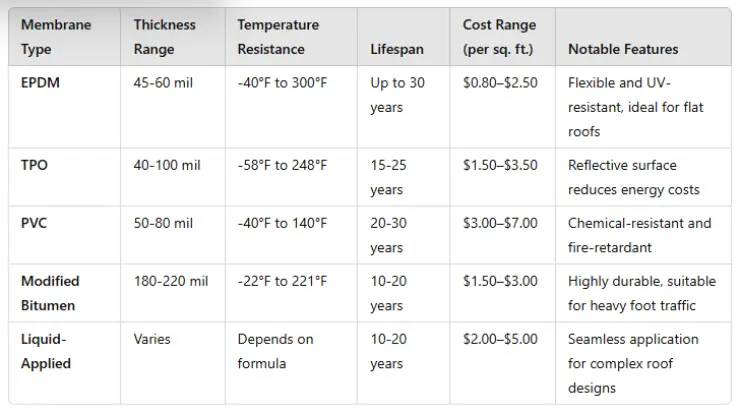

The following table highlights the technical specifications of various roof waterproofing membranes, helping you evaluate which option best suits your project’s needs.

Innovations in Roof Waterproofing Membranes: Emerging Technologies

Advancements in roofing technology are reshaping how waterproofing membranes are designed and applied. Innovations such as self-healing membranes, nanotechnology-enhanced systems, and smart sensors are setting new standards in performance and efficiency.

Polyguard has embraced these trends with products like self-adhesive membranes and energy-efficient claddings, including Deckguard® HT. Designed to reduce environmental impact and boost energy performance, these solutions reflect the company’s commitment to modern sustainability standards and innovation in waterproofing technology.

Self-Healing Membranes

These membranes contain materials capable of repairing small punctures or tears autonomously, reducing maintenance costs and downtime. By using advanced polymers, self-healing membranes provide long-term resilience, making them an attractive option for industrial and high-traffic roofs.

Nanotechnology in Liquid-Applied Systems

Liquid-applied membranes enhanced with nanoparticles improve UV resistance, elasticity, and waterproofing. These systems are particularly advantageous for complex roof shapes and retrofitting, ensuring durability without compromising design.

Smart Membranes with Embedded Sensors

Integrated sensors in some roofing membranes monitor moisture levels and detect potential leaks before they escalate. This proactive approach reduces the risk of major repairs and optimizes maintenance schedules, adding significant value to modern roofing systems.

Eco-Friendly Solutions

Sustainable materials, such as recycled components in waterproofing membranes, are gaining traction. These options align with green building standards and cater to eco-conscious projects seeking long-term performance with reduced environmental impact.

Understanding the different types of roof waterproofing membranes is important, but selecting the right one also involves considering your building’s specific needs and environmental conditions.

Key Considerations for Choosing a Waterproof Membrane for Roof Systems

The selection process for a roof waterproof membrane involves evaluating specific building needs and environmental factors:

Climate and Weather:

Choose membranes that withstand local UV exposure, temperature swings, and precipitation.

Roof Design:

Flat roofs benefit from liquid-applied systems, while sloped roofs require more traditional options.

Building Function:

Industrial facilities may need chemical-resistant materials, whereas office buildings prioritize energy efficiency.

Budget:

Balance initial costs with long-term performance to optimize value.

Once the right membrane type is chosen, incorporating reliable underlayments and complementary products can significantly enhance the overall performance of your roofing system.

Polyguard Waterproofing Solutions: The Foundation of Reliable Roof Systems

Polyguard’s products, like Deckguard® HT, complement EPDM, TPO, and PVC roofing membranes by providing a durable underlayment that enhances waterproofing and prevents water infiltration. Designed for high-temperature performance, Deckguard® HT is trusted by contractors to improve roof system reliability and lifespan.

Maintenance for Long-Term Performance

Proper maintenance is key to maximizing the lifespan and performance of waterproof roofing membranes. By implementing a proactive approach, contractors can help building owners avoid costly repairs and ensure the roof remains in optimal condition.

Routine Inspections

Conducting regular inspections, at least twice a year and after severe weather events, is crucial for identifying potential issues early. Key areas to examine include:

- Seams and Edges: Check for lifting or separation, as these are common entry points for water.

- Membrane Surface: Look for punctures, tears, or signs of wear caused by debris or foot traffic.

- Flashing and Penetrations: Ensure a watertight seal around vents, skylights, and other rooftop features.

Timely Repairs

Addressing small problems promptly can prevent them from escalating into more significant and costly damage. For example:

- Patching Minor Tears: Use manufacturer-approved materials to maintain compatibility with the membrane.

- Reinforcing Vulnerable Areas: Strengthen seams or flashing prone to stress with additional layers or self-adhesive patches.

- Inspect After Repairs: Always check the surrounding areas to ensure no secondary issues are present.

Cleaning and Debris Removal

Keeping the roof surface clean is essential for proper drainage and membrane longevity. Regular cleaning should include:

- Debris Removal: Clear leaves, branches, and dirt that can block drainage systems or trap moisture.

- Gutter and Drain Cleaning: Ensure that all water runoff systems are free from obstructions to prevent pooling.

- Algae and Mold Control: For areas prone to high humidity, clean the surface to prevent organic growth that can degrade the membrane.

Seasonal Adjustments

Contractors should consider the impact of seasonal changes on roof performance:

- Winter Preparations: Clear drains and ensure snow guards are in place to manage ice dams.

- Spring and Fall Maintenance: Focus on removing buildup from seasonal debris like fallen leaves or pollen.

By prioritizing these maintenance practices, roofing contractors can extend the lifespan of waterproof roofing membranes and maintain customer satisfaction by minimizing downtime and repair costs.

Explore Industry-Leading Waterproofing Solutions with Polyguard

Polyguard specializes in advanced waterproofing products that support a range of roofing systems, from underlayments to energy-efficient wraps. Explore how our innovative solutions can enhance your roof's performance. Contact us today for more information.