Blog & News

Explore our articles to learn more about products in application.

Types Of Soil Remediation Techniques For Restoring Contamina...

Soil remediation methods provide contaminated soil solutions to restore soil to its natural, pollution-free state. Remediation of soil pollution purifies and revitalizes the soil by removing…

Best Basement Waterproofing Paint

Moisture damage in basements can lead to serious structural problems, unpleasant odors, and harmful mold growth. Homeowners often turn to waterproofing solutions to keep their basements dry and…

Can Termites Eat Concrete?

The term "concrete termites" conjures images of super-pests chewing through solid building materials. This common misconception leads many property owners to wonder: can termites actually eat…

Best Moisture Barrier for Basement Walls

Water intrusion can devastate basement walls, causing structural damage, mold growth, and expensive repairs. Finding the best moisture barrier for basement walls is crucial for maintaining a dry,…

What Is the Best Underlayment for Tile Floors?

Cracked tiles, moisture damage, and uneven floors are problems no one wants to face. Selecting the best installation layer for tile floors is essential if you want your tiles to last, looking…

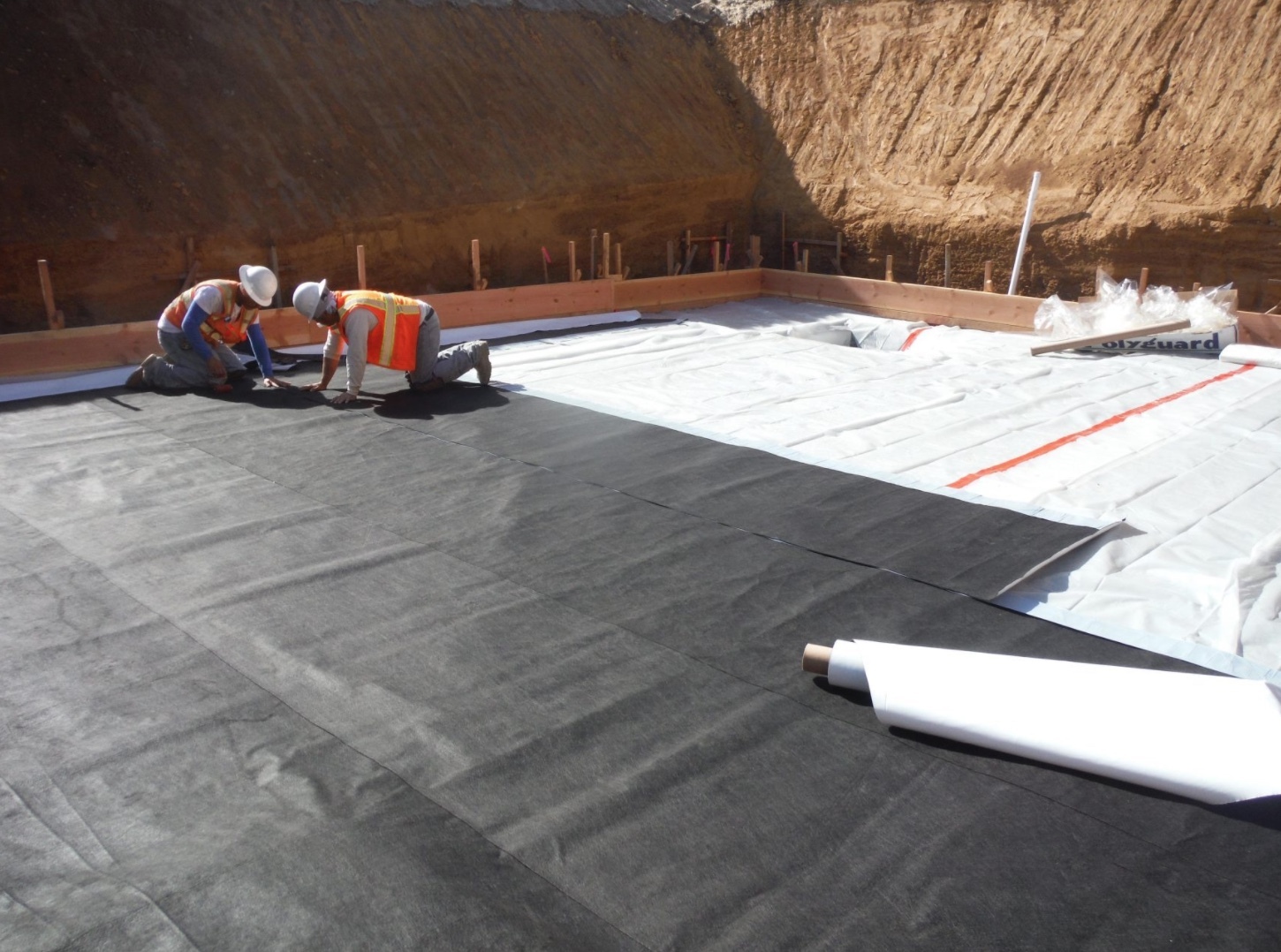

Vapor Barrier vs. Waterproofing Membranes

Vapor barriers and waterproofing membranes limit, if not stop, water infiltration into a structure, which protects its integrity and the occupant's health. However, vapor barriers and waterproofing…

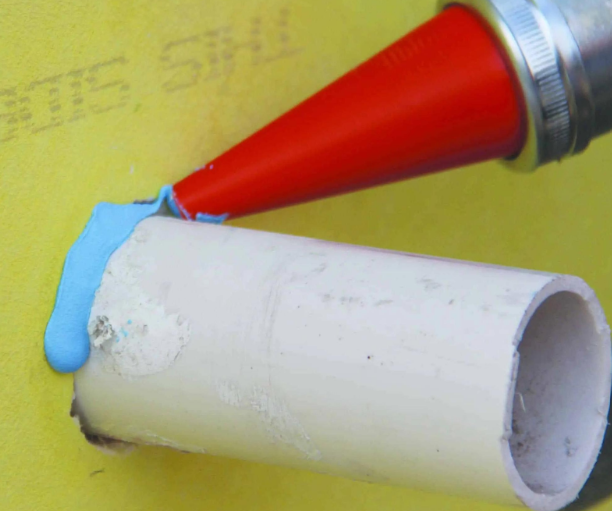

Filling Gap Between Concrete Slab and Wall: Why It Matters a...

Even small gaps—like the ones between concrete slabs and walls—can turn into big problems if they’re left alone. Moisture sneaks in, pests find their way through, and over time, you could be looking…

Tile Underlayment Membrane: The Hidden Foundation of Long-La...

Tile floors and walls are known for looking great and holding up over time. But what you can’t see underneath the tile is just as important as the tile itself. Before tile is installed, the surface…

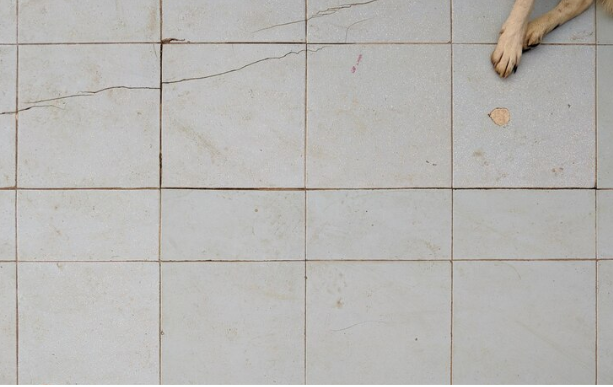

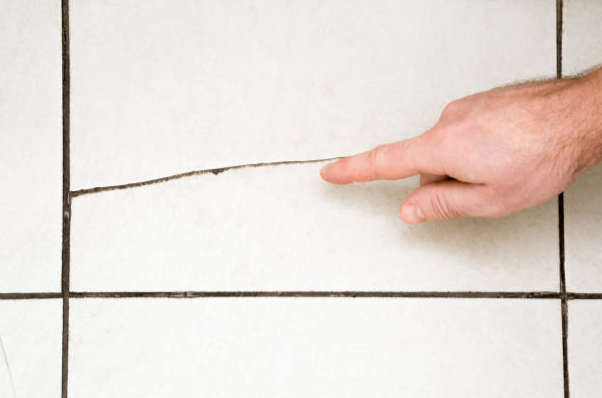

Comprehensive Guide to Crack Isolation Membranes for Tile In...

Tile is only as reliable as what’s underneath it. If the surface below shifts or cracks, it can lead to damage that’s often costly to fix. That’s where a crack isolation membrane comes in—it helps…

Metal Building Window Flashing: A Practical Guide to Getting...

Water finds its way into metal buildings faster than many people expect. If a window isn’t flashed correctly, leaks around the frame can lead to corrosion, ruined insulation, and structural damage…

Does Crawl Space Encapsulation Add Value to Home & Other Ben...

Crawl space encapsulation is more than just a home improvement trend; it’s a strategic investment that offers long-term benefits. Homeowners looking to increase property value, reduce energy costs,…

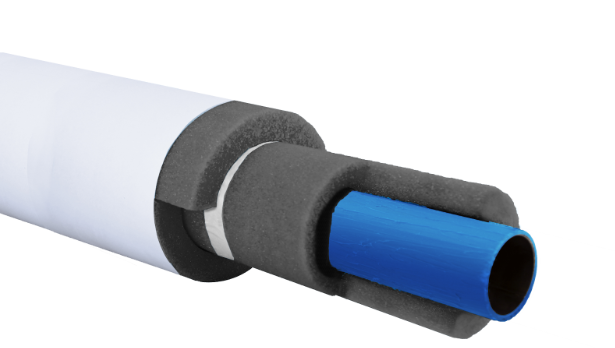

Protecting Your System with Water Line Pipe Insulation

Water line pipe insulation is a practical solution for protecting plumbing systems from the impacts of temperature changes, energy loss, and moisture damage. By applying the right insulation, you can…