Water line pipe insulation is a practical solution for protecting plumbing systems from the impacts of temperature changes, energy loss, and moisture damage. By applying the right insulation, you can stabilize water temperature, prevent pipe deterioration, and enhance overall efficiency in both residential and commercial settings.

Why Water Line Pipe Insulation Matters

Without insulation, water lines are directly affected by their surrounding environment. In cold climates, water inside pipes can freeze, leading to expansion and bursting, which can cause severe property damage. In warm, humid areas, condensation forms on cold water lines, dripping onto surfaces, leading to mold growth, corrosion, and structural deterioration. Insulation acts as a protective barrier, reducing these risks by regulating pipe temperature and limiting direct exposure to external conditions.

Key Benefits of Water Line Insulation

Prevents Freezing and Pipe Bursts

In freezing temperatures, uninsulated water pipes are highly vulnerable to ice formation. They can freeze or expand, increasing internal pressure and potentially causing cracks and burst. This can lead to:

- Extensive water damage to walls, floors, and surrounding structures

- Costly repairs due to pipe replacements and water cleanup

- System failures that disrupt water supply in homes and businesses

Applying water line pipe insulation provides a thermal barrier, helping to:

- Reduce heat loss and maintain a stable internal temperature

- Prevent freezing-related damage, even in extreme winter conditions

- Ensure reliable water flow, minimizing disruptions and costly fixes

By wrapping exposed water lines with properly rated insulation, homeowners and businesses can significantly lower the risk of frozen pipes and expensive damage.

Improves Energy Efficiency

Uninsulated hot water pipes lose heat as water moves through the system, making water heaters work harder to maintain the desired temperature. This results in:

- Higher energy consumption, as more heat is lost before reaching fixtures

- Increased utility costs, especially in buildings with high water usage

- Reduced efficiency, leading to unnecessary strain on heating systems

By adding water line pipe insulation, heat retention improves, helping to:

- Minimize heat loss, ensuring hot water stays warmer for longer

- Lower energy use, reducing the need for frequent reheating

- Improve system efficiency, leading to long-term cost savings

Over time, this simple upgrade can result in significant reductions in energy expenses for both residential and commercial applications.

Controls Condensation and Moisture Damage

When warm, humid air comes into contact with cold water pipes, condensation forms on the surface. Over time, this persistent moisture buildup can lead to corrosion, mold growth, and structural damage in surrounding materials.

Insulating water lines creates a protective barrier that reduces direct exposure to humid air, preventing condensation from forming in the first place. This is especially important in basements, crawl spaces, and unventilated areas, where excessive moisture can cause long-term deterioration of plumbing systems and nearby surfaces.

Extends the Lifespan of Plumbing Systems

Over time, uninsulated pipes are exposed to temperature fluctuations, moisture, and external elements, which can accelerate corrosion, leaks, and structural deterioration. Pipes located in unheated spaces, exterior walls, or underground areas are especially vulnerable to freezing, expansion, and long-term damage.

Proper insulation helps:

- Regulate pipe temperature, reducing exposure to extreme conditions

- Prevent moisture infiltration, minimizing corrosion and rust

- Extend the lifespan of plumbing systems, lowering maintenance and repair costs

By reducing temperature-related stress and environmental exposure, insulation ensures greater durability and long-term system performance in both residential and commercial applications.

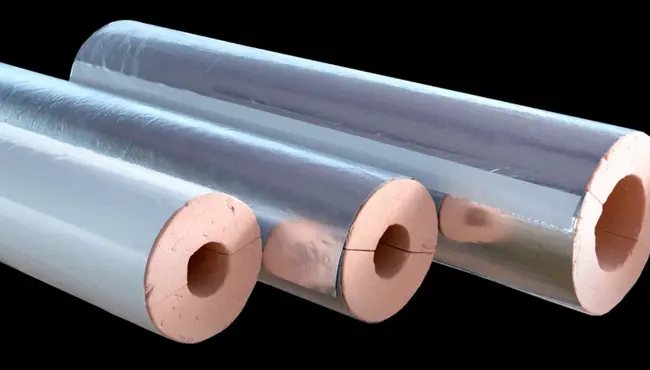

Types of Insulation for Water Line Pipes

Choosing the right water line pipe insulation depends on the pipe’s location, exposure conditions, and thermal performance requirements. Different materials offer varying levels of moisture resistance, heat retention, and durability, making some options better suited for specific applications than others.

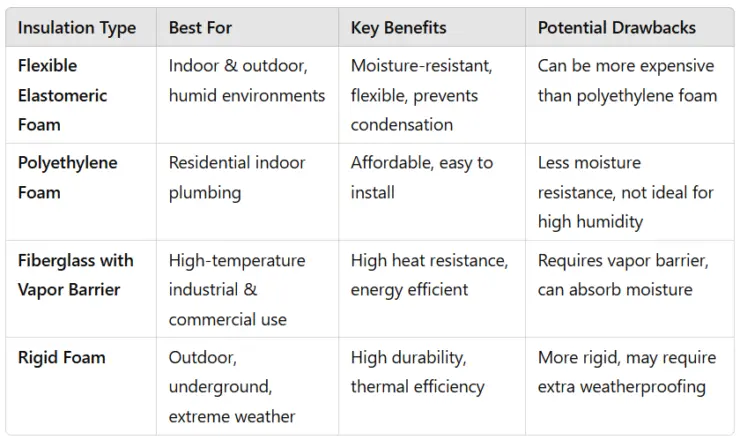

Flexible Elastomeric Foam Insulation

Flexible elastomeric foam is a closed-cell insulation designed for both hot and cold water pipes. Its moisture-resistant structure prevents condensation buildup, making it a strong choice for humid environments. The material’s flexibility allows for easy installation around bends and irregular pipe configurations, while its low thermal conductivity helps reduce energy loss in heating systems.

Polyethylene Foam Pipe Insulation

This lightweight and cost-effective insulation is commonly used for residential plumbing applications. It provides moderate thermal protection for hot and cold water pipes but is less resistant to moisture than elastomeric foam. Because of this, it is best suited for indoor applications where humidity levels are controlled.

Fiberglass Pipe Insulation with Vapor Barrier

Fiberglass insulation is used for high-temperature water lines, particularly in industrial and commercial settings. It offers strong thermal resistance, making it ideal for systems that require consistent heat retention. However, fiberglass is susceptible to moisture absorption, so it is typically installed with a vapor barrier to maintain its insulating effectiveness in damp environments.

Rigid Foam Insulation

For outdoor water pipes, underground plumbing, and extreme weather conditions, rigid foam insulation provides high thermal resistance and long-term durability. It is often paired with weatherproof coatings or UV-resistant wraps to protect against exposure to sunlight, rain, and freezing temperatures.

Best Practices for Installing Water Line Pipe Insulation

Assess the Pipes and Environment

Before applying insulation, inspect pipes for existing damage, leaks, or corrosion. Insulation should only be installed on dry, clean surfaces to ensure proper adhesion. Taking accurate pipe diameter measurements helps select the right insulation for a secure and efficient fit.

Installation Techniques for Maximum Efficiency

To minimize heat loss and moisture infiltration, insulation must fit tightly along the entire length of the pipe. Gaps or exposed areas reduce effectiveness, so seams should be sealed with insulation tape or weatherproof adhesive. For outdoor applications, using a UV-resistant covering helps protect insulation from sunlight, rain, and temperature fluctuations, extending its lifespan.

Protect Your Systems with Polyguard Solutions

Keeping systems protected from moisture, temperature changes, and everyday wear helps maintain performance over time. Polyguard provides solutions designed to help reduce environmental impact and material breakdown in a variety of applications. Contact us today and speak with one of our experts!