Oil and gas pipeline maintenance is vital for the oil and gas industry. Not only does it help ensure resources are transported safely and efficiently, but it also helps the industry manage challenges with old infrastructures, remote areas, and strict regulations.

Maintaining Healthy Pipelines

Healthy pipelines are essential for the operational success of the oil and gas industry, with an emphasis on functionality, reliability, safety, and sustainability:

- A functional pipeline operates efficiently to ensure continuous resource flow with minimal disruptions.

- Reliability involves consistent performance that is supported by regular maintenance and timely upgrades.

- Safety is paramount, to protect workers and the environment through strict regulatory compliance and emergency preparedness.

- Sustainability focuses on environmentally responsible operations that align with global climate goals.

Together, these aspects form the foundation of a holistic maintenance strategy, which is essential for the industry's enduring efficiency and resilience.

Pipeline Maintenance Challenges

Among the most pressing challenges faced by the pipeline maintenance sector, a few stand out due to their complexity and impact on operations:

1. Aging Infrastructure

Pipelines, often decades old, are susceptible to corrosion, cracks, and structural weaknesses. Regular assessments are necessary to prevent failures that could lead to environmental and safety hazards.

2. Remote Locations

The extensive reach of pipelines through isolated and harsh terrains complicates maintenance efforts. Access difficulties necessitate innovative solutions for inspection and repair.

3. Data Management

The extensive data collected from pipeline operations require robust management systems. Efficient data handling enables predictive maintenance to enhance operational safety and reliability.

4. Regulatory Compliance

Meeting the evolving standards and regulations in pipeline maintenance is critical. Compliance ensures not only the integrity of pipelines, it also safeguards environmental and public safety.

5. Advanced Repair Methods

Advanced repair methods, like composite wrap and CISBOT (Cast Iron Joint Sealing Robot), offer efficient solutions to pipeline maintenance. Composite wraps repair and reinforce damaged areas without major service disruptions, while CISBOT seals joints internally in live pipelines, which reduces excavation needs and maintains service continuity. These methods enhance maintenance efficiency and safety.

Best Practices for Pipeline Maintenance

To mitigate these challenges and ensure the continued effectiveness and safety of pipeline operations, certain best practices have emerged as essential components of a comprehensive pipeline maintenance strategy:

6. Regular Inspections and Testing

Incorporating advanced technologies like drones and smart pigs in pipeline inspections aids in early detection of potential issues to prevent costly repairs.

7. Corrosion Management

To combat corrosion, a significant threat to pipeline integrity, the industry employs protective coatings, cathodic protection systems, and continuous monitoring techniques.

8. Leak Detection Systems

Sophisticated leak detection methodologies, including acoustic, infrared, and fiber-optic sensors, are vital for promptly identifying and addressing leaks.

9. Pigging Operations

Regular pigging maintains pipeline cleanliness and functionality to provide critical insights into the internal condition and ensure operational integrity.

10. Routine Maintenance Activities

Comprehensive maintenance programs, including vegetation control, valve inspections, and pressure testing, are essential to maintain pipeline integrity and functionality.

Tips for Improving Pipeline Maintenance

11. Technological Integration

Leveraging Industry 4.0 technologies—predictive analytics, robotics, and automated inspection—enables a shift from reactive to proactive maintenance strategies.

12. Training and Expertise

Continual training and certification, such as API 570, equip maintenance personnel with the necessary skills and knowledge to uphold pipeline integrity.

13. Sustainability Considerations

Efforts to reduce greenhouse gas emissions and operational and capital expenditures are crucial. Sustainable practices not only lower costs, they also align with environmental responsibilities.

14. Methane Recovery and Emission Reduction

Methane recovery and emission reduction are vital in pipeline maintenance and focus on environmental sustainability and resource efficiency. Techniques like pipeline pump downs capture and recycle methane to prevent atmospheric release and support operational efficiency. This approach not only conserves resources, it also aligns with global environmental objectives.

Enhancing Pipeline Integrity with Polyguard Products

Polyguard products feature prominently in addressing these challenges with solutions that enhance pipeline integrity and longevity. From advanced coatings to innovative corrosion protection systems, Polyguard products integrate seamlessly into the maintenance routine to provide reliability and efficiency.

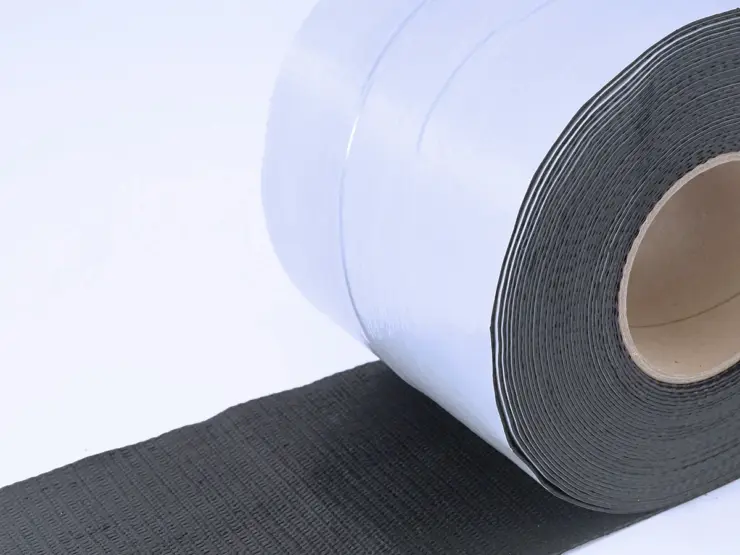

RD-6® Coating System

The Polyguard RD-6® Coating System stands as a revolutionary solution in pipeline integrity and corrosion protection. This non-shielding, anti-corrosive wrap effectively bonds to the pipeline surface to provide a formidable barrier against moisture, chemicals, and soil bacteria. Its ease of application and robust performance make it an ideal choice for both new construction and rehabilitation projects, for the long-term durability and reliability of pipeline systems.

Application

The RD-6® Coating System is particularly beneficial for aging pipeline infrastructure prone to corrosion. Its seamless application process allows for efficient rehabilitation of existing pipelines, to protect against further deterioration and extend their service life.

RD-6® UVO Overcoat

Designed for optimal performance in harsh environments, Polyguard RD-6® UVO Overcoat provides enhanced UV protection for pipeline coatings exposed to direct sunlight. Its application is straightforward and adds a critical layer of durability to the RD-6® coating system for long-lasting protection against degradation. This overcoat is particularly useful in maintaining the integrity of above-ground pipeline sections by safeguarding against the damaging effects of UV radiation.

Application

In regions with high sun exposure, such as desert environments or open fields, the RD-6® UVO Overcoat serves as a reliable solution to prevent UV-induced degradation of pipeline coatings. Its application on above-ground pipeline sections ensures continuous protection against environmental factors.

600 Liquid Adhesive

The 600 Liquid Adhesive is a critical component in Polyguard's arsenal for enhancing pipeline protection. Serving as a high-performance primer, it ensures a strong bond between the pipeline surface and the protective coatings that include the RD-6® Coating System. Easy to apply and quick to dry, the 600 Liquid Adhesive not only improves adhesion, it also significantly extends the lifecycle of pipeline coatings under various environmental conditions. This adhesive is an essential step in achieving comprehensive corrosion protection for pipeline maintenance.

Application

When applying the RD-6® Coating System, the 600 Liquid Adhesive serves as a vital preparatory step that enhances the adhesion of the coating to the pipeline surface. Its quick-drying properties expedite the coating process to minimize downtime during maintenance operations.

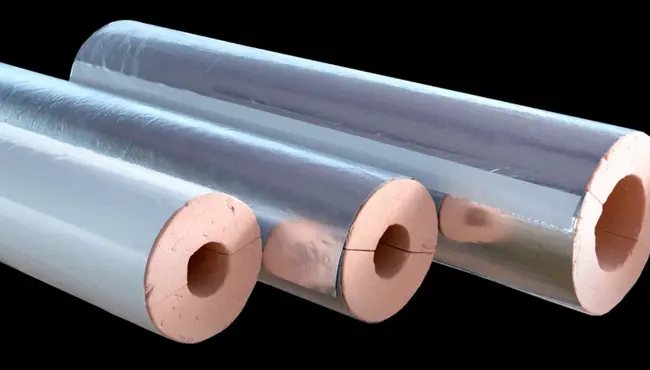

IRO™ (Impact Resistant Outerwrap)

Polyguard's IRO™ (Impact Resistant Outerwrap) provides an extra layer of mechanical protection to pipeline coatings to safeguard against physical impacts and abrasions that occur during backfilling and throughout the pipeline's operational life. This durable outerwrap is engineered to absorb shock and resist damage to ensure that the

underlying coatings maintain their integrity and performance. IRO's ease of installation and compatibility with existing coatings make it a practical choice for extending the longevity and reliability of pipeline systems.™

Application

During pipeline construction or maintenance activities involving backfilling or trenching, the IRO™ serves as a protective layer to shield the pipeline coatings from mechanical damage. Its impact resistance properties mitigate the risk of coating degradation to preserve the integrity of the pipeline system.

These products are part of Polyguard's comprehensive approach to pipeline maintenance with solutions that integrate seamlessly into maintenance routines to ensure pipeline reliability and efficiency.

Polyguard: Pioneering Pipeline Protection for Industry Leaders

Polyguard's commitment to enhancing pipeline maintenance is evident in its comprehensive range of products and services designed to meet the industry's dynamic needs. Our solutions are crafted to ensure the highest standards of pipeline integrity and operational excellence.

Contact us today and speak with one of our experts!