Moisture, chemical exposure, and pH changes are usually addressed early. But temperature receives less attention—especially in non-subsea environments. Understanding how higher temperatures influence pipeline corrosion plays an important role in preparing any project for elevated service conditions.

Elevated Temperatures Accelerate Electrochemical Reactions

Corrosion rates increase with temperature due to faster electrochemical activity. Higher temperatures accelerate the chemical reactions that drive metal oxidation. This is particularly relevant in systems transferring heated fluids or operating near boilers and industrial equipment. For mild steel and other alloys, a rise of just 10°C can nearly double corrosion rates in active environments.

Thermal energy not only speeds up the oxidation process but also lowers the resistance of protective oxide films on metal surfaces. When protective layers break down, the bare metal becomes exposed to water vapor, oxygen, and other aggressive ions. In humid or marine-adjacent climates, this effect can be even more pronounced.

Thermal Stress Can Trigger Stress Corrosion Cracking

Thermal exposure creates conditions where corrosion and mechanical stress interact in destructive ways.

Material Susceptibility and Design Considerations

Not all damage from heat is chemical. Long-term exposure to elevated temperatures can cause stress corrosion cracking (SCC) in susceptible alloys. These failures occur when internal stress and corrosive exposure interact to form micro-cracks in pipe walls or welds. SCC risk rises significantly in high-pressure zones and thermal expansion joints.

Pipelines running near or above 50°C should be assessed for SCC susceptibility. Expansion loops and support design must accommodate thermal movement without concentrating stress near bends or weld points. Duplex stainless steels, carbon steels, and low-alloy materials exposed to chlorides, sulfates, or acidic condensate are especially vulnerable.

Field Failures and Project Risk

Case studies in refineries and subsea systems have documented SCC formation in as little as two years under poorly designed support structures and inadequate surface treatment. These examples demonstrate that higher temperatures may influence pipeline corrosion not only through general wall loss but also by contributing to crack formation at stress risers and weld transitions.

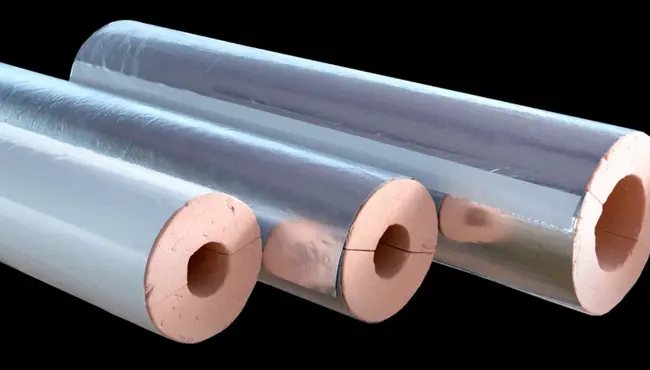

High Heat Degrades Coatings and Barrier Systems

Protective coatings that function well at ambient temperatures may begin to fail under continuous or elevated thermal loads. Coatings begin to peel or blister, allowing moisture to reach the pipe surface. Epoxies soften or lose adhesion above certain thresholds—particularly those not rated for high-glass transition temperatures.

Multi-layer coating systems must include a thermal durability assessment. Heat-resistant membranes or mechanical wraps may be necessary to maintain barrier integrity over time. Polymeric and bitumen-based layers may also outgas or delaminate when exposed to cyclical radiant heat, especially near rooftop risers, steam lines, or exhaust chases.

Cathodic Protection Load Increases with Temperature

As temperature rises, pipelines demand higher CP current density to remain protected. This affects both sacrificial anode and impressed current systems. Electrolyte conductivity and surface activity increase with heat, accelerating anode depletion or requiring more power input from CP rectifiers.

Engineering teams should verify that CP monitoring systems are calibrated to detect temperature-driven shifts in polarization potential. Higher operational temperatures may also require tighter spacing of anodes or use of enhanced conductive backfills. Engineering teams evaluating if higher temperatures influence pipeline corrosion in buried systems must also account for soil resistivity, oxygen availability, and water saturation—all of which shift with temperature.

Thermal Expansion Creates Mechanical Stress Points

Pipelines expand and contract when exposed to heating and cooling cycles. Over time, this movement introduces micro-stress at flanges, gaskets, and support points. These stress concentrations can lead to coating fractures or crevice corrosion—especially where movement occurs beneath insulation or in concealed areas.

Flexible joints and expansion loops reduce fatigue-related corrosion. Isolators, slip supports, and low-friction bearings should be reviewed during system layout to limit cumulative damage from mechanical cycling. These thermal movement effects can also distort CP current paths and require specific design allowances at discontinuities and attachments.

Inspection Strategies for High-Temperature Systems

Inspection strategies must address both corrosion progression and temperature-driven failure modes.

Monitoring Tools and Inspection Intervals

High-temperature pipeline inspection programs must evolve beyond standard intervals. Tools such as thermal sensors, CP probes, and localized ultrasonic testing help capture active corrosion zones under heat stress. Technicians use these methods to detect corrosion hotspots and microcracks before they weaken the structure.

Inspection frequency may also need to increase. In environments with fluctuating loads or high humidity, semi-annual testing can reveal early failures missed by annual schedules. Inspection planning should be grounded in a clear understanding of material behavior in elevated temperature environments.

Diagnostic Methods and Response Planning

Additional diagnostic methods—like magnetic particle inspection or phased-array UT—can help verify whether crack propagation is thermal-fatigue or chemical in nature. Asking do higher temperatures influence pipeline corrosion should prompt a more tailored inspection response based on material, layout, and service temperature.

Ambient Design Assumptions Can Lead to Failures

Designs based on ambient conditions often fail to account for the corrosive effects of sustained thermal exposure.

Risks of Underestimating Thermal Load

Ambient design estimates often fall short in high-temperature systems, leading to premature failure. Materials and coatings rated for moderate service can degrade when exposed to sustained thermal loads. These conditions are common in power generation, chemical processing, and central utility systems—yet are often underestimated during initial specification.

Long-Term Impact on Material Performance

Systems designed for high-temperature fluid transport—such as boiler loops or thermal transfer lines—require early attention to corrosion behavior at elevated operating ranges. Failure to match materials to these conditions increases risk of joint leaks, structural fatigue, or asset loss.

Knowing if higher temperatures influence pipeline corrosion is no longer optional in commercial and industrial design. It is a planning prerequisite for safe long-term operation.

Field-Tested Solutions for Thermal Corrosion Protection

Polyguard designs protective membranes and corrosion barriers specifically for elevated-temperature environments. These materials are tested for adhesion, chemical resistance, and vapor permeability under heat stress. They remain stable in hot soils, above-grade risers, and pipe chases exposed to radiant loading.

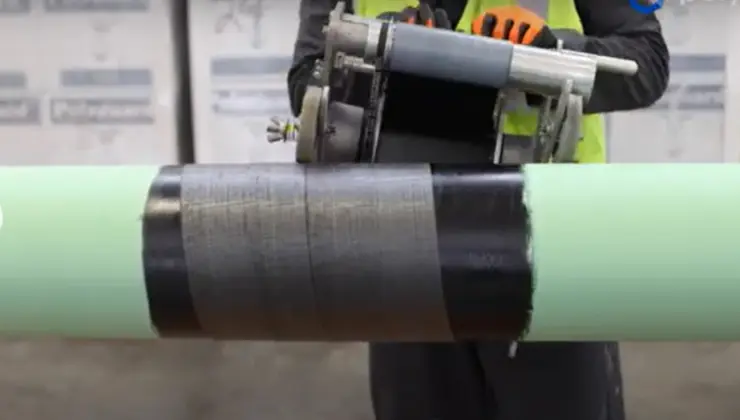

Recommended Polyguard Products for High-Temperature Service

RD-6® Coating System is a non-shielding, geotextile-backed wrap designed for use on buried or submerged pipelines. It maintains bond integrity at elevated soil temperatures and supports cathodic protection function, even in thermally active zones. The HD/HT variant extends performance up to 88 °C, making it suitable for high-load or radiant-exposed installations.

RG-2400® ET Corrosion Gel is formulated for high-temperature service on insulated or exposed pipe surfaces. It penetrates into the metal substrate and creates a stable mineral barrier that resists under-insulation corrosion. The product remains effective through thermal cycling, with rated performance up to 177 °C (350 °F).

Protect Critical Infrastructure with Polyguard High-Temperature Barrier Systems

Protecting pipelines from heat-induced corrosion begins with accurate specification. Our engineered coatings and membranes are designed to maintain adhesion, resist moisture intrusion, and support cathodic protection—even at elevated temperatures. These systems extend infrastructure life and reduce long-term maintenance costs. Contact us today for more information.