Every pipeline is only as strong as its weakest weld. In high-stakes energy and industrial systems, even a single unprotected joint can become a corrosion hotspot. A girth weld coating restores corrosion protection at joints where welding removes the factory-applied layer, preventing localized weaknesses from threatening the integrity of the entire system.

How Weld Joint Protection Safeguards Pipeline Integrity

Pipeline girth welds face unique mechanical and environmental challenges that demand targeted protection.

Vulnerabilities at Weld Joints

In industrial and energy sectors, pipeline protection is measured in decades of field performance. The girth weld area faces the same external forces as the rest of the line but with an added challenge: it is a fabricated interface between two pipe segments. Weld bead geometry, heat-affected zones, and metallurgical changes create surface irregularities and corrosion initiation points.

Role of the Girth Weld Coating

Without a suitable coating, moisture and contaminants can settle in microscopic crevices, accelerating electrochemical reactions that cause pitting or undercutting of the weld. Its role is to span these irregularities, bond securely to both the weld and adjacent pipe coating, and maintain that bond through thermal cycles and ground movement.

Material Selection and Surface Preparation Standards

Material selection begins with adhesion requirements. The coating must anchor firmly to bare steel on the weld bead and transition smoothly onto the adjacent mainline coating without creating a stress riser at the overlap.

- Standards such as NACE SP0394 outline surface preparation practices that improve adhesion.

- Grit blasting to a near-white metal finish (SSPC-SP 10/NACE No. 2), followed by preheating, creates the clean, dry substrate essential for a lasting bond.

Even the most advanced coating cannot compensate for poor preparation — the interface must be mechanically and chemically ready to receive the new layer.

Durability and Performance Testing

Effective girth weld protection depends on both physical toughness and proven test performance.

Environmental and Mechanical Resistance

Durability drives long-term success. The coating must withstand mechanical handling during lowering-in and backfilling, as well as extended exposure if backfill is delayed. In above-ground service, ultraviolet radiation can degrade polymers without proper stabilizers. Below ground, coatings must resist soil stress, rock impingement, and water ingress over decades.

Laboratory Performance Benchmarks

Abrasion resistance testing, such as ASTM D4060 Taber wear, and impact resistance testing per ASTM G14, provide measurable indicators of toughness. Products that retain their integrity under these tests are more likely to survive real-world conditions without degradation.

Compatibility with Mainline Coating Systems

Maintaining a continuous protective barrier depends on proper bonding between the girth weld coating and the mainline system.

Common Mainline Coating Types

Modern pipelines may use fusion-bonded epoxy (FBE), three-layer polyethylene (3LPE), or three-layer polypropylene (3LPP). The selected material must bond chemically and mechanically to these surfaces without causing brittleness or delamination.

Preventing Interface Failures

Incompatible materials create weak transition zones that allow moisture to migrate under the mainline coating. Experienced crews often conduct small-scale peel tests before full application to confirm adhesion, ensuring the chosen material integrates with the system.

Environmental Factors During Application

Application success depends on managing temperature and humidity during installation.

- In arid regions, high daytime temperatures can accelerate curing but risk trapping solvents if rushed.

- In cold or damp environments, slow curing extends vulnerability before backfilling.

- Many specifications define minimum and maximum environmental limits to prevent these problems.

Coatings with wide application windows give field crews flexibility to maintain schedules without sacrificing quality.

Application Methods for Different Project Needs

Application methods vary by project.

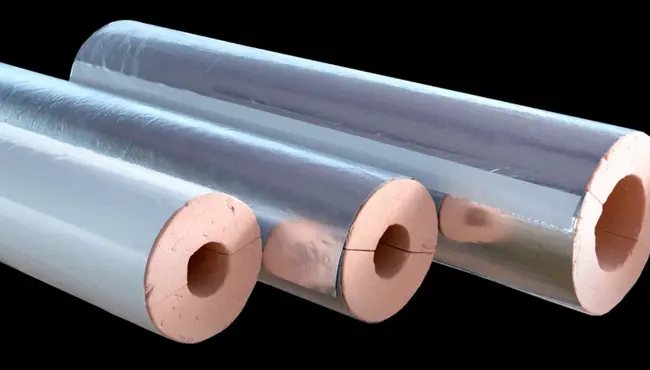

- Liquid-applied systems, such as epoxy or polyurethane, conform closely to weld contours and are applied using brush, roller, or spray.

- Heat-shrink sleeves combine a polymer backing with an adhesive layer that activates under heat, shrinking tightly for a mechanical and adhesive seal.

- Multi-component systems may add a liquid primer with a wrap or sleeve to enhance barrier properties.

Each approach balances installation speed, handling requirements, and long-term performance.

Risks of Skipping or Improper Application

Skipping or mishandling a girth weld coating can lead to severe structural and financial consequences.

Corrosion and Structural Weakness

The risks of skipping or improperly applying this protection are documented in failure analyses. Corrosion at welds can propagate circumferentially and longitudinally, weakening the pipe wall and threatening pressure containment. Even minor pitting at a weld can initiate cracks under cyclic pressure changes.

Costly Remediation Requirements

Field repairs drive up costs, forcing excavation, shutdowns, and often environmental remediation. These operational risks far outweigh the time and cost of applying the right coating during construction.

Inspection and Quality Assurance

Inspection and quality assurance close the loop.

- Holiday detection using low- or high-voltage methods identifies pinholes or thin spots in the coating.

- Adhesion tests, measured in pounds per inch (ASTM D4541), confirm that the applied material meets project specifications.

Documenting these inspections ensures every weld joint matches the protection level of the mainline coating. Some operators link inspection data to GPS coordinates, creating a maintenance-ready record of each coated joint.

Performance Demands in Harsh Environments

As pipelines are built in harsher environments — from arctic permafrost to high-salinity coastal zones — demands on weld protection grow. Coatings must stay flexible in extreme cold, resist chemical attack from aggressive soils, and retain adhesion through repeated freeze-thaw cycles.

The system design, including primers, wraps, and topcoats, should account for every environmental and operational stress anticipated over the pipeline’s life. Selecting a material proven in similar service reduces the risk of premature failure.

Polyguard Product Solutions for Girth Weld Protection

Polyguard’s systems address multiple coating challenges, from corrosion control to abrasion resistance in demanding environments.

Core Girth Weld Coating Systems

The RD-6® Coating System is a non-shielding, geotextile-backed solution designed for fast application and immediate backfill, maintaining strong adhesion to both bare steel and mainline coatings. For pipelines operating at higher temperatures, RD-6 HT extends performance up to 190 °F (88 °C) without loss of bond strength.

Outer Wrap Protection for High-Abrasion Scenarios

In high-abrasion installations such as horizontal directional drilling, X-Wrap and X-Wrap HD act as impact-resistant outer wraps, preserving coating thickness and integrity during pull-through and backfill. These systems integrate to deliver long-term girth weld coating performance in a wide range of field conditions.

Protect Pipeline Welds with Polyguard Girth Weld Coatings

We deliver advanced solutions in this category, with coatings engineered for long-term protection in the industry’s most demanding applications. These formulations are built for strong adhesion to both bare steel and mainline coatings, maintaining bond strength through temperature extremes and ground movement. Contact us today for more information.