Steam systems depend on insulation. One of the most important elements is the choice of steam pipe insulation material. Contractors and facility managers know that the right insulation strategy can extend the life of a mechanical system, meet code requirements, and lower operating costs over decades of use.

Why Steam Pipe Insulation Matters

Steam pipe insulation matters first and foremost for energy efficiency.

- Uninsulated pipes lose significant heat to the surrounding environment, forcing boilers to work harder and increasing utility expenses.

- Worker safety is another important driver, as surface temperatures on unprotected steam pipes can exceed levels that cause severe burns on contact.

- Condensation control also plays a role, since poorly insulated lines are more likely to collect moisture and promote corrosion that weakens both piping and surrounding structures.

- Similar principles apply to water line pipe insulation, where moisture protection is just as foundational to long-term system reliability.

Beyond these performance concerns, codes and standards such as ASHRAE 90.1 and local energy codes require minimum levels of insulation on mechanical systems, making compliance part of every project specification.

Common Steam Pipe Insulation Materials

Several types of insulation are used on steam lines, and the choice of material depends on temperature, environment, and performance priorities.

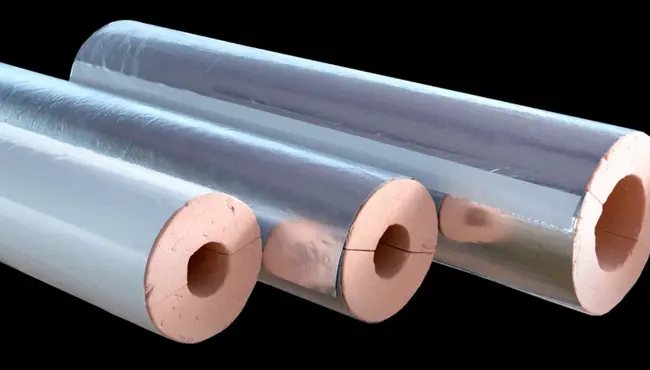

Fiberglass

Fiberglass remains one of the most common, favored for its relatively low cost and ease of handling. It performs well in high-temperature conditions but requires protective jacketing or vapor barriers to keep moisture out, since water intrusion can degrade its thermal resistance. Typical fiberglass pipe insulation is rated for continuous use up to around 850°F, though performance declines if moisture penetrates the jacket.

Mineral Wool

Mineral wool is another widely used option, providing non-combustible protection that can withstand extreme heat without losing form or efficiency. Mineral wool insulation commonly carries a service temperature rating of 1,200°F or higher, making it suitable for demanding industrial steam systems. Contractors often choose mineral wool for industrial applications where fire resistance is a priority.

Calcium Silicate

Calcium silicate has a long history in steam piping insulation, valued for its durability and ability to resist physical abuse in mechanical rooms or exterior locations. It also offers high compressive strength, often exceeding 100 psi under ASTM C533, which makes it a strong choice where piping may be subject to mechanical impact.

Foam Glass and Aerogels

Foam glass and advanced aerogel products fill specialty niches, delivering low thermal conductivity and moisture resistance for highly demanding environments, though they come at higher cost and installation complexity.

Key Performance Factors in Steam Line Insulation

Each insulation material brings unique benefits and limitations, which is why evaluating performance factors is so important. Selecting the correct steam pipe insulation material ensures compliance, safety, and long-term efficiency across mechanical systems.

Thermal Conductivity and Thickness

Thermal conductivity determines how effectively insulation limits heat transfer, with lower values indicating better performance. The right thickness must be specified based on pipe diameter, operating temperature, and efficiency goals, and resources such as the U.S. Department of Energy provide charts and calculators to guide these decisions. For example, DOE testing shows that a bare 350°F steam pipe loses roughly 850 Btu per linear foot per hour, a loss reduced by more than 90% with proper insulation.

Code Requirements and ROI

ASHRAE 90.1 and local energy codes also set minimum insulation thicknesses for steam piping, which ensures not just energy conservation but also predictable system performance. Thicker insulation generally improves efficiency but must be balanced against space constraints and installation costs. Contractors often evaluate return on investment by comparing initial material and labor expense against projected fuel savings, which can be significant over the lifespan of a system.

Worker Safety and Moisture Resistance

Surface temperature limits also matter, since codes specify maximum allowable exterior temperatures to protect workers. Moisture resistance is another key consideration, as water penetration can reduce insulation performance and accelerate corrosion under insulation.

Durability and Maintenance

Long-term durability cannot be overlooked, because insulation exposed to vibration, impact, or weathering must be inspected and repaired to preserve performance. By focusing on these criteria, facility managers can protect both operating budgets and worker well-being over time.

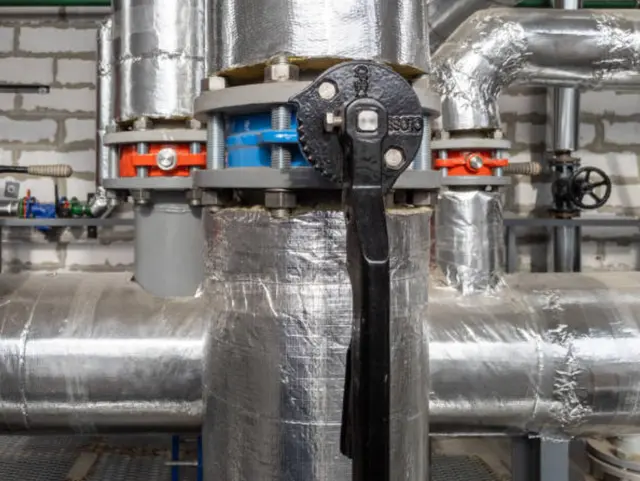

How to Insulate Steam Pipes in Industrial Systems

Installing insulation for steam pipes in industrial systems requires planning and attention to detail. The process begins with reviewing the system layout, identifying pipe sizes, fittings, and temperature ranges. The choice of insulation must match both operating conditions and environmental exposure.

- Insulation should fit tightly to the pipe surface without gaps, with sealed joints preventing thermal bridging, while vapor barriers and jacketing add protection in high-humidity environments.

- Mechanical protection may also be required in exposed areas to shield insulation from impact or abrasion.

- After installation, contractors and facility staff should establish inspection schedules, looking for signs of damage, wet spots, or compression that can reduce thermal efficiency.

Routine maintenance keeps steam line insulation working as designed for decades.

Challenges and Mistakes to Avoid

Many common mistakes can compromise the value of even the best insulation for steam pipes. One of the most frequent errors is underspecifying thickness, which leaves systems vulnerable to unnecessary energy losses and higher surface temperatures. Another is overlooking vapor barrier protection, especially in humid environments where condensation can quickly penetrate and deteriorate insulation.

Some projects fail to account for code requirements, leading to costly corrections or fines during inspections. Others skip ongoing maintenance, allowing insulation to degrade unnoticed until efficiency drops or corrosion becomes visible. Avoiding these pitfalls requires a balance of engineering guidance, compliance awareness, and field-tested installation practices.

Polyguard’s Role in Steam Piping Protection

Polyguard contributes to steam piping projects by addressing risks that insulation alone cannot solve, extending the protection and service life of mechanical systems.

Beyond Insulation Alone

For many building owners and operators, the question becomes not only how to insulate steam pipes but how to do so in a way that supports long-term system reliability. While insulation materials provide the primary line of defense, other protective measures extend their performance.

Protective Barriers and Coatings

This is where Polyguard reinforces long-term system reliability. Our solutions are not insulation products themselves, but rather barrier membranes, coatings, and jacketing systems that prevent moisture and contaminants from reaching mechanical components.

- ZEROPERM® Vapor Barrier Membrane provides zero-perm protection that stops vapor drive from penetrating fiberglass or mineral wool insulation, preserving thermal performance over time.

- Alumaguard® Jacketing Systems combine vapor barrier performance with durable exterior protection, making them a reliable choice for above-grade piping where insulation must resist weathering and mechanical damage.

By pairing the right steam pipe insulation material with these protective solutions, contractors and facility managers can ensure energy savings, worker protection, and durability align for decades of service.

Proven Performance in the Field

Polyguard has spent decades helping the industry address hidden risks such as moisture penetration and below-grade deterioration. In the context of steam piping insulation, our membranes and protective systems provide proven protection by working alongside insulation to stop external conditions from undermining system performance. Contractors who integrate both insulation and protective barriers into their projects reduce repair budgets, extend service life, and improve compliance outcomes.

Protect Mechanical Systems with Polyguard Solutions

Protecting mechanical systems is an investment in reliability and compliance. With the right steam pipe insulation material, supported by Polyguard’s building protection solutions, owners and contractors can prevent energy losses, limit maintenance costs, and keep workers safe. Contact us today for more information.