Water pipelines form the backbone of our daily water supply by ensuring that both homes and businesses have access to clean, potable water. Their maintenance is not just a routine task, but a necessity to prevent disruptions and ensure the longevity of these critical infrastructures.

This article considers the importance of water pipeline maintenance, explores common issues affecting pipelines, and introduces effective maintenance techniques and products from Polyguard that can help in mitigating these types of problems.

The Different Types of Water Pipelines

Water pipelines are integral to societal well-being, and they come in various forms: municipal, agricultural, and industrial, each fulfilling essential roles:

- Municipal pipelines ensure the delivery of potable water, and are vital for public health.

- Agricultural pipelines, crucial for irrigation, can directly influence food production and water conservation.

- Industrial pipelines support key processes in manufacturing, and require stringent maintenance for efficiency and safety.

Constructed from resilient materials such as PVC, steel, and copper, these systems require stringent maintenance routines. The difference between residential and commercial pipelines highlights the need for customized maintenance approaches to ensure a dependable water supply. This underscores the importance of recognizing and tackling the distinct challenges posed by each type of pipeline.

Addressing Common Pipeline Issues and Their Broader Consequences

Pipeline integrity is compromised by leaks, corrosion, and blockages that can lead to immediate challenges like water loss and potential long-term infrastructure damage. These problems not only incur significant repair costs, they can also disrupt the quality and flow of water, which poses risks to public health and safety.

The Far-Reaching Effects of Pipeline Neglect

The neglect of maintenance tasks amplifies the environmental, economic, and health repercussions of pipeline failure:

- Environmental impacts include water scarcity and ecosystem harm due to leaks and contaminants.

- Economically, the costs of emergency interventions far surpass those of regular maintenance, which affects community budgets.

- Health-wise, the risks of waterborne diseases increase with the deterioration of water quality, which highlights the necessity of a proactive maintenance strategy to safeguard infrastructure and community well-being.

Detailed Water Pipeline Maintenance Techniques

To ensure the longevity and reliability of water pipelines, maintenance can be categorized into preventive, corrective, and predictive approaches, each vital to a comprehensive maintenance strategy.

Preventative Maintenance

Preventive maintenance focuses on regular checks and routine activities to prevent failures. This includes scheduled inspections, cleaning, and the replacement of parts that have a known lifespan. The goal is to catch and address potential issues before they escalate into major problems.

Corrective Maintenance

Corrective maintenance is performed after a failure has been detected and aims to correct the fault so the pipeline can be returned to service. Techniques vary based on the issue, but can include patching leaks, replacing sections of pipe, or applying corrosion protection measures.

Predictive Maintenance

Predictive maintenance leverages technology to predict when a maintenance task should be performed. This approach uses sensors and data analytics to monitor the condition of the pipeline in real time, in order to preduct potential failures before they occur. Examples include the use of smart sensors to detect changes in pressure or flow that could indicate a leak or blockage.

Incorporating these maintenance techniques ensures a proactive approach to managing water pipeline infrastructure, to significantly reduce the risk of unexpected failures and extend the service life of the system.

Highlighting Polyguard Pipeline Products

Polyguard offers a range of products designed specifically for water pipeline maintenance. These products provide solutions that enhance the protection and longevity of pipelines by addressing common issues such as corrosion and leaks. The benefits of utilizing Polyguard products include extended pipeline life and improved reliability of the water supply system.

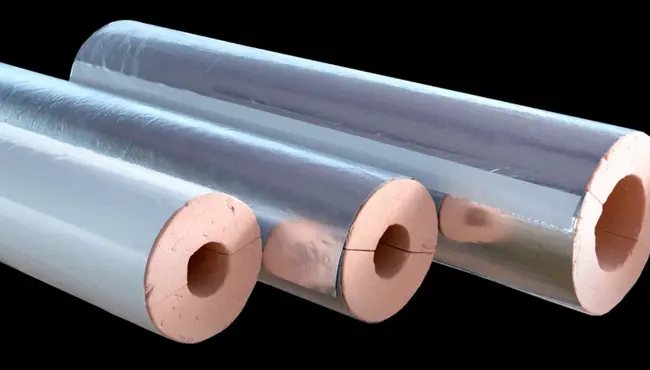

RD-6®

RD-6® coating system offers advanced external protection for pipelines. It's a non-shielding, anti-corrosion coating that's easy to apply and provides strong protection against environmental and chemical corrosion. It's perfect for new builds and rehab projects alike.

CA-9™ Mastic

CA-9™ Mastic is a cutting-edge coating solution that seals pipeline fittings, joints, and welds against moisture and corrosion. It's straightforward to use and flexible, which makes it a key part of any pipeline maintenance plan. The formula is tough, and it provides lasting protection in tough environments.

RD-6® HT

RD-6® HT is Polyguard's innovative solution for pipelines in high-temperature environments. Designed specifically for extreme temperatures, this coating system stays protective when ordinary coatings fail. It's perfect for industrial uses where resisting high temperatures is crucial.

Best Practices in Water Pipeline Maintenance

Effective pipeline care and maintenance incorporate a blend of best practices, including:

- Regular professional evaluations to assess the condition of pipelines and identify potential issues

- Adoption of new technologies and methods for early detection and prevention of leaks, corrosion, and blockages

- Implementation of a scheduled maintenance program to ensure ongoing care and upkeep of water pipelines

Explore Polyguard's Solutions for Water Pipeline Integrity

Ensuring the integrity and longevity of water pipeline systems is crucial for maintaining public health, safety, and environmental well-being. Polyguard's innovative maintenance solutions provide a robust defense against common pipeline issues for enhanced system reliability. Explore our range of products, including RD-6® and the 600 Liquid Adhesive to safeguard your water pipeline infrastructure against corrosion, leaks, and other potential threats.

Contact our experts today to learn more about how our products can be the key to effective water pipeline maintenance and the preservation of a clean, uninterrupted water supply.