Internal pipeline coating helps maintain the integrity and efficiency of pipeline systems.

Because corrosion can lead to significant economic losses, environmental hazards, and safety concerns, pipeline construction and maintenance managers need to use effective pipeline coatings to ensure the longevity of pipelines.

Understanding Internal Pipeline Coatings

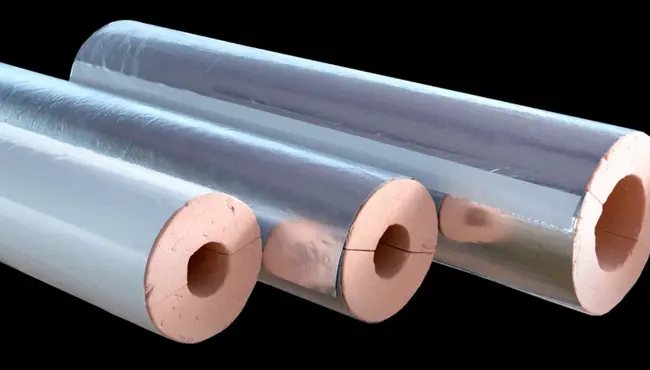

Internal pipeline coating involves applying a protective layer to the interior surfaces of a pipeline that prevents corrosion and reduces friction within the pipeline.

These coatings act as barriers against corrosive substances and environmental factors that can degrade the pipeline material over time. For pipeline managers, however, understanding the different types of coatings and their applications can help them select the best coating method.

Types of Internal Pipeline Coatings

In terms of internal pipeline coating, there are 4 types that you should be aware of. For instance:

Fusion-Bonded Epoxy (FBE) Coatings

Fusion-Bonded Epoxy (FBE) coatings are high-performance anti-corrosion coatings that are applied as a powder, which later melts and bonds to the pipe surface when heated, forming a hard, protective layer.

It’s suitable for temperatures up to 120°C and is known for providing excellent adhesion, chemical resistance, and durability.

They can also be applied to various pipe sizes and provide superior long-term corrosion protection, which makes them ideal for harsh environments like oil and gas pipelines.

Application Process

1. Surface Preparation: Thoroughly clean using abrasive blasting to remove rust and contaminants, to achieve a roughness value of 50-100 microns.

2. Heating: Induction or oven heat the pipe to 180-250°C.

3. Coating: Use a spray gun to apply the FBE powder uniformly while the pipe rotates.

4. Curing: The melted powder forms a solid coating through chemical cross-linking that results in a durable protective layer.

Cement Mortar Linings

Cement mortar linings are another type of internal pipeline coating, which are commonly used for the protection of water pipelines.

They provide long-term protection by creating a stable hydroxide film at the steel-mortar interface, which acts as a barrier against corrosion, and the type of lining is known for its cost-effectiveness and ease of application.

Benefits

- Active corrosion protection even at discontinuities in the lining

- Long-term durability and low maintenance

- Suitable for large-diameter pipelines.

Liquid Epoxy Coatings

Liquid epoxy coatings are also applied to the internal surfaces of pipelines that prevent corrosion. These coatings are known for their strong adhesion, chemical resistance, and ability to provide a smooth internal surface, which reduces friction and improves flow efficiency.

Application Process

1. Surface Preparation: Clean the internal surface to remove contaminants.

2. Coating Application: Use airless spray equipment to apply the epoxy coating evenly.

3. Curing: Allow the coating to cure and form a hard, protective layer.

Key Benefits of Internal Pipeline Coatings

Internal pipeline coatings offer multiple benefits, including

- Corrosion prevention

- Flow efficiency

- Maintenance costs

By minimizing friction and turbulence within the pipeline, these coatings enhance flow rates and reduce energy costs. Not to mention, because they reduce the amount of repairs in the future, they are a more cost-effective solution for maintaining pipelines.

Cost Considerations for Pipeline Coatings

The cost of internal pipeline coatings, however, depends on several factors, including material costs, application methods, pipeline size and condition, and additional services like inspection and testing.

Why Use Internal Pipeline Coatings?

Internal pipeline coatings help pipelines meet environmental regulations and safety standards such as ISO 21809 and NACE, and the compliance ensures the pipelines safe and reliable

But internal pipeline coatings also reduce downtime and enhance the reliability of pipelines by protecting against corrosion and other environmental factors, which leads to fewer interruptions.

Protect the Internal Pipeline by Protecting the External Surface

Protecting the longevity and reliability of pipeline systems, however, is limited by how well the external surface of a pipeline is protected. In other words, there is a clear relationship between the protection of the external pipeline and the internal pipeline's longevity.

To ensure your internal and external pipeline safety, explore high quality pipelines coating protection materials, such as those offered by us at Polyguard. For instance:

The RD-6® Coating System

The RD-6® Coating System by Polyguard is a non-shielding anti-corrosion system used on buried and submerged pipelines, as well as rehabilitation and new construction girth welds. This system consists of a liquid adhesive, a geotextile-backed protective coating, and the SP-6™ outerwrap. It is suitable for pipelines operating up to 145°F (63°C), with RD-6 HT® available for higher temperatures. The RD-6® coating provides excellent resistance to soil stress and can be backfilled immediately after application.

The RD-6 HT® Coating System

The RD-6 HT® Coating System is designed for high-temperature applications, up to 190°F (88°C). Similar to the RD-6® system, it includes a liquid adhesive, geotextile-backed protective coating, and SP-6™ outerwrap. The RD-6 HT® provides superior resistance to cathodic disbondment, even with less-than-ideal surface preparation.

The SP-6™ Unbonded Outerwrap

The SP-6™ Unbonded Outerwrap is an integral part of the RD-6® Coating System. It consists of a non-woven, felt-like polypropylene fabric engineered to provide high bursting strength and low tensile and elongation properties. Unlike bonded outerwraps, the SP-6™ outerwrap moves independently of the anti-corrosion coating layer, to reduce the transfer of soil stress to the underlying coating and prevent deformation and electrolyte penetration.

The UV Overcoat

The UV Overcoat (UVO) is a highly resistant coating that protects the RD-6® anti-corrosion coating from damaging UV rays. It is a single-component, low-VOC, water-based liquid coating that can be applied with a brush, roller, or airless spray method. The UVO coating ensures the durability and effectiveness of the RD-6® system when used above ground, by preventing UV-induced degradation.

By utilizing Polyguard's advanced external coating systems, pipeline operators can significantly enhance the protection of both external and internal surfaces of pipelines to help ensure long-term reliability and operational efficiency.

Use Advanced Coating Solutions From Polyguard to Protect Your Pipeline

Partner with Polyguard for top-tier pipeline coatings that ensure unmatched corrosion protection and operational efficiency.

Our expertise and innovative products will help to safeguard your pipeline investments and enhance project success.

Contact us today for more information.