Polyguard now master distributor for Powersleeve, Aquawrap

Texas-based Polyguard Products Inc. is proud to announce that it is now the master distributor of the Aquawrap and Powersleeve brands of products, manufactured by Field Applied Composites Systems (F.A.C.S.).

Aquawrap and Powersleeve add to Polyguard’s current line of products – including its RD-6 Wrap and NHT-5600 two-part epoxy. The adjacent market Aquawrap and Powersleeve serves expands the diversity of solutions the industry has counted on from Polyguard over the past 70 years.

Polyguard will stock both the Aquawrap and Powersleeve and their accessories at its manufacturing headquarters in Corsicana, Texas. The goal is to provide expedited access to customers in the region with a more centralized distribution point.

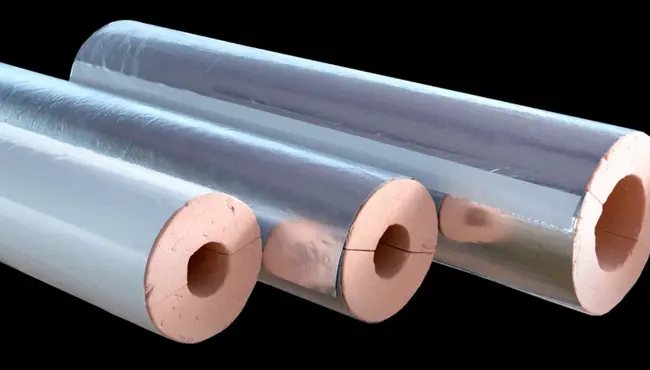

Aquawrap® BP-1 is a low-cost composite system for use in repair and reinforcement of existing mechanical systems, structures and piping. Furnished factory-impregnated fabric with the proprietary 22-77 resin system and the unique BP-1 urethane primer. It is odorless and solvent-free. Cured Aquawrap® is a very durable, high strength, long-term material, impervious to fuels, most chemicals and solvents. It permanently bonds to a wide variety of surfaces such as metals, composites, concrete, plastics and wood. This product meets the requirements of the ASME PCC-2 standard and is certified to ANSI/NSF Standard 61 when the BP-1 primer is used. The Aquawrap® fabric is ready to apply, right out of the bag and cures by way of a chemical reaction with field-applied water. This offers considerable advantages over conventional cloth-resin systems in that there is no resin measuring, mixing, spreading, solvents, or dripping polymer residue.

Powersleeve® Carbon is available in two bi-axial fabrics; a 12” wide, 18 oz. stitched fabric and a 6 oz. tape available in 2”, 4” and 6” widths for spiral wrapping smaller diameter pipes. This product is designed for applications where high strength and/or modulus are required. It can be used for the repair and reinforcement of existing mechanical systems, structures, and piping. The cured product is a very durable, high strength material, impervious to fuels, most chemicals and solvents. It permanently bonds to a wide variety of surfaces such as metals, composites, concrete, plastics and wood. The 12” wide, 18 oz. product is especially useful in the repair of large diameter piping systems and provides a cost-effective alternative to our glass reinforcement systems.

Please email pipeline@polyguard.com for more information.