Approved air barrier materials include features that ensure minimum code compliance based on the environment, wall design, and building use and type. Builders can use various air barrier materials or continuous film or coating as long as it includes the following attributes:

- There must be continuous installation over the whole building enclosure, with all terminations and penetrations thoroughly sealed.

- The air barrier must tolerate ultraviolet light, freezing, thawing, and precipitation to maintain its integrity over the building's expected lifetime.

- Meet permeability requirements or Impermeable to airflow:

- The ASTM E2178 mandates that an air barrier's air permeance is no higher than 0.02 L/(s·m²) at a pressure difference of 75 Pa (0.004 cfm ft2 at a pressure difference of 1.56 lb ft2). Air permeance is the amount of air that flows through a material. In contrast, air leakage flows through holes, gaps, and cracks.

- The ability to resist forces, like dimensional stress or changes, that act on them during and following construction.

NOTE: The success of an air barrier system depends on following the manufacturer's installation instructions and adequately integrating the air barrier system and building enclosure components.

What is an Air Barrier?

Air barriers help produce sustainable, energy-efficient, long-lasting, comfortable, and healthy buildings.

A properly installed air barrier system should continuously prevent air (and the moisture associated with it), heat, and moisture infiltration and exfiltration in and out of the building envelope. The building enclosure includes the below- and above-grade elements that physically separate the interior and exterior environments of the building.

Air barriers can be either impermeable or vapor permeable (allowing vapor to pass through).

Meeting Air Barrier Code Requirements

An approved air barrier must comply with the IRC (International Residential Code) and the IBC (International Building Code) code requirements for residential and commercial buildings.

Commercial Buildings

The 2021 IBC, Section C402.5.1, mandates a continuous air barrier around the building envelope for commercial buildings (except climate zone 2B). Additionally, builders can place air barriers inside or outside the building envelope, within the envelope assemblies, or any combination thereof. The air barrier must meet the requirements of Sections C402.5.1.1 and C402.5.1.2.

Residential Buildings

The 2021 IRC (Table R402.4.1.1) mandates sealing breaks in its joints and applying a continuous air barrier in a building envelope. IRCs cover detached one-and-two residential buildings and townhouses no higher than three levels above the grade plane.

They should also have a separate means of egress with accessory structures (e.g., barns, garages, carports, playhouses, sheds, private greenhouses) no higher than three stories above the grade plane.

The IBCs apply to all structures that do not conform to the required provisions of the IRC.

Designing an Approved Air Barrier System

An approved air barrier design must consider the climate, wall design, building type and use, and substrate.

Climate Considerations

The air barrier system design must consider the climate zone. Climate conditions directly impact energy efficiency and moisture control. Each zone presents unique challenges to an air barrier's performance.

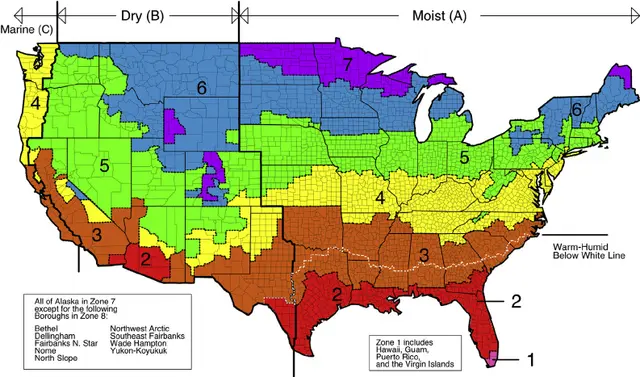

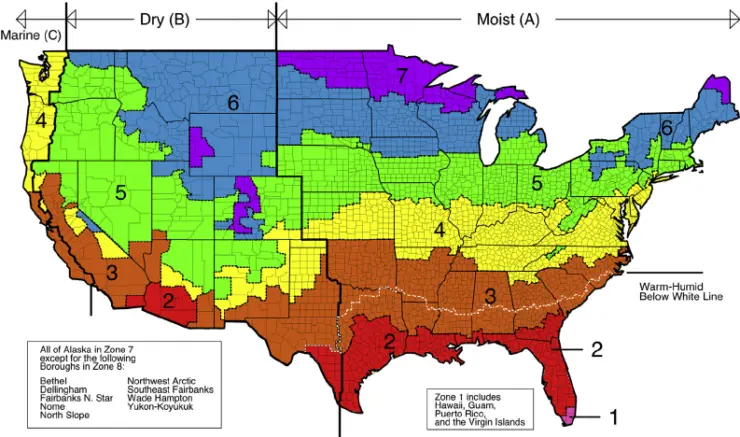

The U.S. climate zone map includes eight temperature zones. Further divisions in the map divide the regions by moisture levels designated A, B, and C, which creates 24 potential climate designations within the IECC map. For reporting reasons, the IECC divided the zones into five climate categories: cold/very cold, hot-humid, hot-dry/mixed dry, mixed-humid, and marine.

The parameters of climate regions include average temperatures, heating degrees, and precipitation.

Wall Design/Substrate Considerations

Selecting the right air barrier must take into account the wall assembly design, including:

- The substrate that the barrier will attach to?

- The complexity of the design details. Does it contain geometries or rough surfaces?

- Is the insulation's location only in the cavity, stud spaces, or split between the stud space and cavity?

- Does the design need compliance with NFPA 285?

Building Use and Type

An approved air barrier design should consider the intended use, building type, and design - all of which impact the building's interior climate (relative humidity and temperature).

Achieving an Approved Air Barrier with Polyguard Products

Polyguard offers high-quality permeable and impermeable fluid-applied barriers and five self-adhesive, non-permeable air barriers.

Polyguard Fluid-Applied Air Barriers

Polyguard above-grade fluid-applied air barrier for application to most substrates include Airlok® Flex® VP and Stretch Flex

Airlok® Flex® VP

Water- and acrylic-based, permeable, single-component, cold fluid-applied Airlok® Flex® VP elastomeric membrane prevents air and moisture infiltration while still allowing water vapor to escape. Airlok® Flex® VP allows for applications between 40°F (4.4°C) and 120°F (48.8°C) and provides one year of UV resistance.

Stretch Flex

Polyguard vapor-impermeable Stretch Flex allows for application temperatures ranging from -20°F (-29 °C) to 120°F (48.8°C) and provides six months of UV resistance.

Polyguard Self-Adhered/Peel-and-Stick Membranes

Polyguard’s self-adhesive, non-permeable membranes come with similarly specified complementary flashing products. Polyguards also offer a series of fluid-applied flashing and detail products.

Airlok® Sheet 200 BU/NP

Non-permeable, self-adhesive 28-mil, 100-foot laminated butyl Airlok® Sheet 200 BU/NP sheet membrane bonds to a cross-laminated polyethylene sheet designed for air and moisture applications. Builders can use Airlok® Sheet 200 BU/NP as a field membrane, through-wall flashing, and window flashing, like brick facades.

Airlok® Sheet UV 200 BU/NP

Self-adhesive, non-permeable 28-mil Airlok® Sheet UV 200 BU/NP consists of a foil/polyscrim film laminated to a butyl layer designed for air and moisture applications. Airlok® Sheet UV 200 BU/NP offers one-year UV exposure. Airlok® Sheet UV 200 BU / NP can be used as field membranes and window flashings for high UV exposure assemblies due to extended construction schedules.

Airlok® Sheet 400 HT/NP

Non-permeable, self-adhesive, 40-mil, 36-inch x 75-foot laminated, modified asphalt Airlok® Sheet 400 HT/NP sheet membrane bonds to a cross-laminated polyethylene sheet designed for moisture and air applications. Airlok® Sheet 400 HT/NP can be used for high-temperature field membrane, window flashing, and through-wall flashing for assemblies like metal cladding and coping caps.

Airlok® Sheet 400 NP

Non-permeable, self-adhesive, modified-asphalt, 40-mil Airlok® Sheet 400 NP sheet membranes bond to a cross-laminated polyethylene sheet, which makes it suitable for air and moisture applications. Airlok® Sheet 400 NP field membrane can be used for window flashing, and through-wall flashing like brick facades.

Airlok Sheet UV Ultra 400

Non-permeable, self-adhesive, 40-mil Airlok® Sheet UV Ultra 400 composite sheets and complementary flashings consist of a durable foil facing laminated to a rubberized asphalt layer, designed for two years of UV exposure. Airlok® Sheet UV Ultra 400 can be used as field membranes and window flashings for high UV exposure areas due to long construction schedules

Understanding Approved Air Barrier Materials

Approved air barrier materials, like Polyguard fluid-applied and self-adhered high-quality air barriers, must comply with current code requirements and meet permeability requirements based on the environment, wall design, and building use and type.

Achieving an air-tight building envelope requires the installation of a long-lasting, approved air barrier continuously over the building envelope.

Contact our Polyguard architectural professionals for more on understanding approved air barrier materials and the benefits of applying Polyguard’s fluid and self-adhered air barriers.