Closed-cell foam insulation is a superior and effective insulator for attics, crawl spaces, rim joists, pole barns, existing homes and buildings, vans, new construction, and more.

The best closed-cell foam insulation offers several significant features that contribute to a sustainable and safe building:

- A relatively high R-value of 6.5 to 7 per inch, which more effectively prevents heat transfer and enhances your building's efficiency and comfort, compared to other insulation types like fiberglass and cellulose, with an R-value of 3.5 and 3.7

- A thickness of 1.5 inches creates an air barrier and a perm of less than 1, making it vapor semi-impermeable and preventing condensation without a vapor barrier

- A sheer density that provides structural integrity

Spray Closed-Cell Foam Insulation?

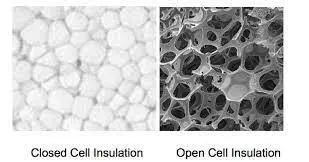

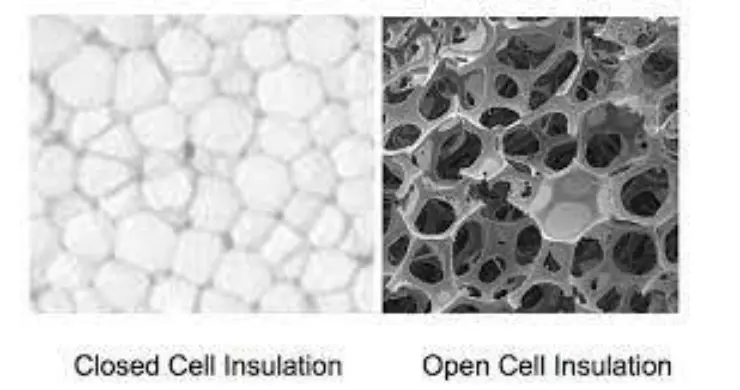

A spray gun dispenses two chemicals from separate tanks (typically isocyanate and polyol resin) that meet at the tip to form a foam. Once sprayed into the intended areas, the foam expands rapidly into unconnected-uniform cells, quickly filling the small nooks and crannies, to provide excellent coverage, and create an effective air, vapor, and sound barrier.

The Advantage of Choosing the Best Closed-Cell Foam Insulation

Closed-cell foam insulation offers builders and designers several significant benefits for new and remodeled construction:

Moisture Impermeability

Closed-cell insulation does not absorb moisture; only the surface becomes moist, which protects the structure's integrity. Additionally, if water enters a damaged area of the closed-cell insulation, it will not spread.

Air-Barrier That Resists Convection

The compact design of closed-cell foam provides a greater R-value that resists heat transfer through convection.

Durable Closed-Cell Foam Density

- The dense composition of closed-cell insulation creates high compressive strength

- Structural support

- Impact resistance

- Resistance to extreme weather events, like hail and severe winds

Improved Air Quality

Closed-cell insulation significantly improves air quality by blocking toxins and preventing unhealthy mold growth.

FAQ - Closed-Cell Foam Insulation

Spray polyurethane closed-cell insulation in residential building envelope applications has grown from 1 percent to over 15 percent over the last 20 years, largely due to its ability to minimize air and moisture leakage and provide structural support. However, questions about its application still circulate in the construction industry.

As A Vapor Retarder, Can Builders Use Closed-Cell Foam In Warm, Humid Climates?

Closed-cell foam has a perm rating of 1 per 2 inches and an R-value of 6.5 to 7 that helps manage air and moisture infiltration through the foam, which prevents condensation. 1 inch of foam will prevent condensation in warm and mixed climates, while 2-3 inches will prevent condensation in colder climates.

Does Spray Foam Release Toxic Gases, Such As Formaldehyde, After It Cures, Which Diminishes Indoor Air Quality?

Spray polyurethane closed-cell insulation does not contain formaldehyde. Furthermore, the fumes and mist that develop during application dissipate within 24 hours of application.

Can Builders Install Closed-Cell Foam Installed To The Underside Of Wood Roof Decks?

Yes, closed-cell spray foam correctly installed to the underside of the wood decking seals cracks and crevices in the wood deck. Water that gets past the roofing system stays on the wood deck's top so that gravity takes it down to the edge of the building and off the roof. In addition, spray foam keeps a roof deck cold, to minimize ice damming in cold climates and further reduce the chance of water damage to the building.

What Is the Best Closed-Cell Foam Insulation?

The best closed-cell foam insulation provides air and moisture resistance, durability, and improved air quality.

Vital features of closed-cell foam insulation contributing to its high performance include its high R-value of 6.5 to 7 per inch, low permeability of 1, and sheer density. Choosing the best closed-cell foam insulation will lower energy bills, save money, and protect your building's integrity and health.

For more information, don't hesitate to contact our team of Polyguard® professionals.