Concrete block walls made of concrete masonry units (CMUs) are an economical and efficient method for constructing above grade and foundation walls.

A building's long-term integrity and safety depend on covering the concrete walls in order to prevent water infiltration. Waterproofing also provides insulation benefits and can reduce insect problems. Designing a concrete wall without adequate waterproofing can cause uneven floors, cracked walls, and expensive and complicated repairs.

Polyguard waterproofing products help to ensure protection against moisture and air infiltration by hydrostatic pressures and capillary action in the most severe conditions to maintain a building's long-term integrity, safety, and health. For help selecting the best products and methods for coving your concrete block walls, contact our Polyguard waterproofing professionals today.

Concrete Block Walls

Concrete block walls typically use large (8-in or 10-in wide and 16-in long) hollow concrete blocks; however, the size varies depending on the building's weight load. To optimize stability and strength, workers install the blocks in a running bond pattern with steel reinforcing bars inserted in the core of the blocks. Next, mortar joins the blocks together, which rest on concrete footings.

The Pros of Concrete Block Walls

Properly built concrete block walls offer more compression strength than a poured concrete foundation, which means a concrete block wall can hold more weight on the foundation's top.

Concrete blocks do not require forms (like those needed for poured concrete foundations) to configure and secure the blocks.

Concrete blocks do not require a ready-mixed plant, like poured concrete foundation.

Concrete blocks do not require curing time, like poured concrete walls.

Builders can reinforce concrete blocks with steel rebar and mortar to create strong walls.

The uniform size of concrete blocks makes them easy to stack.

The Cons of Concrete Block Walls

Moisture problems with concrete block walls mandate quality air and moisture barrier coverings.

Concrete Blocks Are Porous

Concrete blocks' large pores make them semi-permeable (3.2 perms per inch of thickness) and susceptible to water and vapor intrusion due to capillary action. Capillary action refers to water's ability to flow into narrow channels between porous building materials, like concrete.

Erosion

Water and weather can wear down the mortar used to join concrete blocks together which can cause leaks. Joint areas will develop hairline cracks as the wall responds to soil settlement and hydrostatic pressure. Hydrostatic pressure happens when gravity pushes static (stagnant-dense) water (hydro) against below grade walls built entirely below the water table, or partially on a hillside. Hydrostatic pressure rises with depth and soil wetness and causes moisture to infiltrate through joints and cracks, that will permeate solid concrete through wicking (capillary action).

Other Problems with Concrete Block Construction

Concrete blocks are heavy: 8-in blocks weigh 36 lbs, and 10-in blocks weigh 42 lbs.

Improperly reinforced concrete blocks create weak walls.

Concrete block foundations may bow and buckle if the water around a structure's soil builds up, which can result in expensive repairs.

Concrete block walls have good load-bearing strength, but can lose lateral stability if not fully grouted with rebar.

10 Steps To Cover Concrete Block Walls

Successfully covering and sealing concrete block walls against moisture and air leaks by hydrostatic pressures, capillary action, hairline cracks, worn down mortar, etc., involves the proper application of a system of high-quality waterproofing products like

Polyguard's architectural products.

Step 1. Waterproofing manufacturers vet and test their products to work seamlessly together. Therefore, waterproofing professionals strongly recommend using products from a single manufacturer for your system.

Step 2. Follow manufacturer instructions, and pay special attention to the application products in recommended temperature conditions.

Step 3. To ensure the successful and long-lasting performance of the moisture barrier products, gather your tools and materials and properly prepare the substrate.

Clean the concrete surfaces to remove all damaged mortar, overcoating, paint, efflorescence, or contaminants to achieve an open pore profile and ensure adherence and performance of the sealant.

Smooth and fill rough flush concrete, surface protrusions, defects, and voids greater than 1/2-inch in depth with a high-quality product like Detail Sealant PW™ or Polyguard BB GF (Blue Barrier Gap Filler). Allow the products to dry according to the manufacturer's instructions before applying flashing and air barrier.

Step 4. Apply a sealant to the concrete block. Covering a concrete block wall with a quality sealant, like Polyguard's Airlok Flex®, will help prevent water and soluble contaminants, such as chlorides, from infiltrating porous concrete.

Polyguard Airlok Flex®

Protect and seal concrete walls against moisture and air intrusion with permeable, water-based, non-combustible Airlok Flex® WG (Weather Guard) and WG LT (Weather Guard Low Temp) above grade air, weather, and vapor coverings.

Polyguard's Airlok Flex® barrier systems spray or roll directly on the block wall's bare side for a first-line of defense against moisture infiltration. Builders can use both products on concrete walls and plywood, exterior-grade gypsum sheathing, and oriented strand board (OSB) for long construction schedules.

Airlok Flex® WG and Airlok Flex® WG LT contain a non-combustible, water-based blend of high-performance, elastomeric acrylic polymers. However, Airlok Flex® WG LT contains selected fillers with a VOC content of 115 g/L, while Airlok Flex® WG contains a VOC content of 79 g/L.

Temperature Limitations

Airlok Flex® WG application temperatures start at 40°F (5°C) and above.

Airlok Flex® WG LT application temperatures begin as low as 20°F (-6°C) to no more than 65°F (18ºC).

Benefits of Water-Based Airlok Flex® WG and Airlok Flex® WG LT include:

Simple to prep, roll or spray, and clean up - saving both money and time

Blocks inward-moving water from penetrating through the coating to the substrate to lessen energy loss

Permeable up to 21 perms

NFPA 285 compliant

20 wet mils to 10 dry mils

UV resistance of 2 years

Low cost

Forms durable protection up to 100 PSI adhesive pull-off strength

Note: Do not apply sealant if you plan to use stucco since it requires some moisture to stick. The sealant will impair the stucco's ability to bond to the substrate.

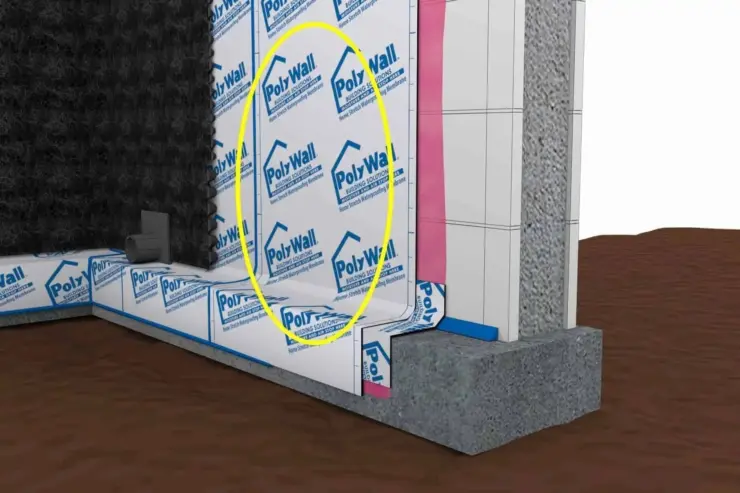

Step 5. Use a breathable-permeable barrier. A breathable-permeable barrier, like Polyguard Poly Wall®Blue Barrier™Liquid Wrap 2300, forms a hydrophobic barrier within (and on) the block's surface to repel moisture and vapor. The barrier also allows moisture within the block to evaporate. It can replace house wrap products because it bonds directly to the substrate.

Poly Wall® Blue Barrier™ Liquid Wrap 2300

Eco-friendly Polyguard Poly Wall® Blue Barrier™ Liquid Wrap 2300 allows the substrate to breathe and cure over damp, above grade concrete walls. It is a thin mil, seamless substrate coating that creates a fully-adhered, protected moisture and air-building envelope membrane that was developed using the latest Silyl Terminated Polyether Technology (STEP).

Benefits of Polyguard PolyWall® Blue Barrier™ Liquid Wrap 2300 include:

Blue Barrier™ Liquid Wrap 2300 is a single component that does not require priming.

It applies by hand, power rolling, or with an approved airless sprayer.

It works with Blue Barrier 2400 Flash ‘N Wrap Window and Door fluid applied Flashing as a complete system.

It offers embedded adhesion (bond) into the wall substrate - other products provide only surface adhesion properties.

It has a low VOC.

It is mold-resistant.

It can be used for wet surface applications.

It is permeable.

Step 6. Use a weather-resistant elastomeric layer. Peel-and-stick UV2-40 minimizes the threat of condensation within the concrete block by repelling water during rains and general exposure. The elastomeric nature of UV2-40 allows it to stretch and not tear if the structure moves slightly. UV2-40 is UV-resistant for up to two years of sunlight without compromising its waterproofing capabilities.

Polyguard UV2-40 (Formerly Aluma Flash Plus)

Rubberized asphalt, UV2-40 is a waterproofing sheet membrane that is laminated to two high-strength polyethylene films with a top protective aluminum layer. Polyguard coating is in the form of rolls with an easy-to-remove film release sheet.

To ensure an impermeable barrier, prime the substrate with Polyguard 650 LT Liquid Waterproofing Adhesive, then apply the Aluma Flash™ by overlapping seams by 2 to 3 inches. Next, use a bead of Polyguard BB GF over the seams for an added layer of protection.

Step 7. Apply a high-quality peel-and-stick waterproofing barrier for concrete block foundations. Peel-and-stick waterproofing membrane barriers provide a uniform surface to dimensions of a factory-set thickness. They do not need fastening and taping. A quality peel-and-stick waterproofing barrier for concrete block foundations, like Home Stretch™ Peel ‘N Stick/ICF Waterproofing Membrane (the pink stuff), will provide long-term performance, durability, and adhesion when correctly applied.

Home Stretch™ 'Peel ‘N Stick/ICF Waterproofing Membrane

Home Stretch™ Peel ‘N Stick waterproofing membranes are made from high-density polyethylene (HDPE) facing that is sealed to a rubberized asphalt waterproofing compound in order to provide strength and flexibility. Home Stretch™ is available in 36-inch wide by 66.7-foot long rolls for easy application, and it includes an expendable release liner.

Builders can use Home Stretch™ high-quality waterproofing to ensure long-lasting protection for below grade CMU, ICF, and poured concrete walls. It can also be used for spaces with positive-side hydrostatic pressure or in crucial need of waterproofing.

Benefits of Home Stretch™ include:

Exceptional puncture resistance, tensile strength, and durability

Release film protects the adhesive layer and does not easily tear

ClearBond can be used to apply Poly Wall® Home Stretch™ in frigid weather (25℉ and greater)

Extended selvage edge for asphalt-to-asphalt adhesion at the seam

Starts waterproofing immediately after installation

Side lap design more effectively delivers water tightness

Factory-controlled manufacturing offers 40-mil uniform and consistent thickness

Lacks VOCs and is odorless

To maximize the waterproofing system, Polyguard suggests using Home Stretch™ in combination with their BB GF (Formerly Blue Barrier 2200), Detail Tape, Totalflow, 650 WB (Water Based) Liquid Adhesive, Stretch Flex, Quick Grip, and Polyflow 10.

Step 8.Apply elastomeric Polyguard Stretch Flex over below grade concrete block, precast concrete, CMU, and other vertical surfaces to combat hydrostatic pressure. Next, apply the liquid membrane (without priming) using a roller, power roller, or airless sprayer.

Polyguard Stretch Flex (formerly Home Stretch Liquid Waterproofing)

Polyguard Stretch Flex is solvent-based and cures to form a durable membrane capable of bridging up to 1/16th inch cracks. When used with Polyguard Polyflow® 10 and Blue Barrier Gap Filler, Stretch Flex is a complete foundation wall waterproofing system. However, builders should not use it for above grade applications, or horizontal substrates like decks, patios, roofs, or over ICF systems.

Step 9: Apply a continuous air and moisture barrier to limit air movement and water vapor in and out of the structure. The best moisture barrier for sealing concrete block walls allows moisture to flow through it, which prevents condensation within the wall system. Air and moisture barriers come in many forms (sheets, self-adhered membranes, liquid membranes, and insulating boards), and the wire ties that stick out from concrete walls make fluid-applied barriers best for sealing concrete block walls.

PolyguardAir and Moisture Barriers

Polyguard Building Solutions provide quality protection against air and moisture infiltration for above- and below-wall systems, to ensure a high-performing building envelope as well as the long-term integrity of the structure. Polyguard’s air and moisture barrier systems include liquid flashings, air barriers, below grade waterproofing systems, and window and door flashings.

Don't hesitate to call the team of Polyguard waterproofing professionals (214-515-5000) to help select the best air and moisture barrier for your concrete block wall project.

Step 10: For new concrete block wall construction, install exterior drain boards. Installing a drainage board (mat) creates an air gap that directs water away from the concrete foundation. Without a drainage board, water will pool at the foundation's bottom.

Stopping water and harmful contaminants from entering the building requires a high-quality, below grade waterproofing membrane and drain board, like Polyguard below grade waterproofing and drainage board for foundation walls.

Polyguard For Superior Drainage Options

Polyguard offers engineered solutions to drain, collect, and redirect water away from a concrete block wall.

Polyflow® 10, 15, and 15P Sheet Molded Drainage Mats

Polyflow® 10, 15, and 15P Sheet Molded Drainage Mats are installed vertically over Polyguard waterproofing membranes to direct moisture into the drain core and minimize soil particle movement, which can clog the core. In addition, Polyflow® 10, 15, and 15P drainage mats can also limit hydrostatic pressure when connected to the high-capacity collector and outlet drainage system, Totalflow™.

Polyflow® 18 DRAINAGE MAT

Polyflow® 18 offers a lightweight, high-capacity drainage system that is compatible with Poly Wall engineered liquid and sheet membrane products used for below grade waterproofing.

Polyflow® 18 drainage mats are straightforward to install, and provide a compressive strength of 21,000 psf, capable of handling the most complex horizontal applications. It is designed with a woven filter fabric that is specifically for concrete pours to allow flow under loaded conditions.

Polyguard - The Best Products for Covering Concrete Block Walls

Concrete block walls are an economical and efficient method for constructing above grade and foundation walls. Builders need to adequately cover the concrete block walls in order to prevent water and air infiltration and ensure durable, strong, and safe structures. Waterproofing also creates insulation and lessens insect problems.

Polyguard waterproofing products are a superior solution for protecting concrete block walls against moisture and air infiltration, and contributing to a building's long-term integrity, safety, and health.

Don't hesitate to contact Polyguard today for more information on covering concrete block walls.