Insulated concrete forms (ICF) create airtight wall systems that minimize moisture intrusion through thermal convection. The permeability of ICF ensures that if moisture gets in, it will evaporate out - a vital component to stopping structurally damaging and unhealthy mold growth.

To avoid ICF moisture problems, the structure must include the following design features:

To avoid leaks around above-grade ICF wall openings at the walls' roofline, doors, and windows requires applying proper flashing, like Aluma Flash™

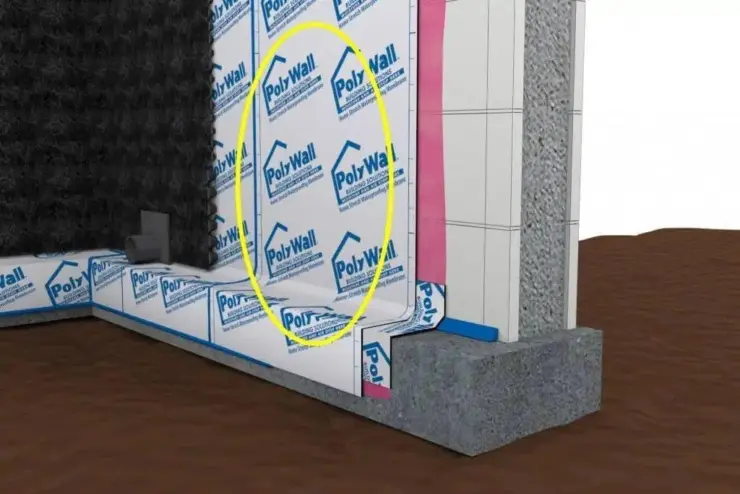

Moisture problems in below-grade ICF walls due to hydrostatic pressure and capillary action requires installing quality waterproofing (Home Stretch™ 40 Mil Membrane) and adequate drainage systems (Polyflow® 10).

Waterproofing ICF Below-Grade Walls

The site's rainfall, drainage, and soil condition all contribute to the need and extent of moisture protection for the below-grade wall.

In addition, building codes specify a foundation level or type of water protection: damp proofing or waterproofing.

The 2021 International Residential Code (IRC R406) designates the conditions requiring damp proofing or waterproofing or damp proofing.

The IRC mandates damp proofing from the top of the footing to the finished grade for any masonry or concrete foundation walls that retain earth and enclose below-grade interior spaces and floors.

The IRC requires waterproofing in areas with a high water table or severe soil-water conditions.

Furthermore, the American Concrete Institute (ACI 515.1) defines waterproofing as treating a structure or surface to prevent water intrusion under hydrostatic pressure. In contrast, they define damp proofing as treating a surface or structure to prevent water intrusion without hydrostatic pressure.

Waterproofing vs. Damp Proofing

Waterproofing protects against hydrostatic pressure. Hydrostatic pressure happens when gravity pushes static-dense water against below-grade walls built partially or completely below the water table or on a hill, that causes liquid water to flow through cracks and joints, and permeate solid concrete through capillary action (wicking). Notably, hydrostatic pressure increases with soil wetness and depth.

Damp proofing prevents soil moisture from infiltrating the wall. It does not protect against water under pressure. Therefore, damp proofings work best in relatively dry building sites.

ICF Below-Grade Waterproofing System

A below-grade ICF wall waterproofing system includes a barrier and drainage system. A high-performing system will effectively stop moisture infiltration, accumulation, condensation, and structurally damaging and unhealthy mold and mildew.

Common waterproofing barriers include peel-and-stick (self-adhered) membranes and liquid waterproofing systems (sprayed, rolled, or towel applied). However, builders commonly prefer easy-to-apply peel-and-stick waterproofing membranes over liquid-applied waterproofing membrane ICF Peel-and-stick waterproofing membrane peel barriers create a uniform surface due to factory-set thickness dimensions. In addition, they do not need fastening and taping.

A dimple drainage board over the membrane adds protection and hydrostatic pressure relief. Dimpled drainage mats allow the moisture in the soil adjacent to the wall to filter through the fabric, down the dimple board and drain board, and finally into the drain tile.

Home Stretch™ 40 Mil Membrane

Polyguard® engineered peel-and-stick Home Stretch™ 40 Mil Membrane specifically for ICF technology or other critical waterproofing application or systems that are subjected to hydrostatic pressure like below-grade concrete masonry units (CMU) and poured concrete foundation walls.

Strong, flexible, self-adhering Home Stretch™ 40 Mil waterproofing membranes consist of high-density polyethylene (HDPE) facing bonded to a rubberized asphalt waterproofing compound. Home Stretch™ 40 Mil comes in 36-inch wide by 66.7-foot long rolls for quick and easy handling and application, with an expendable treat release liner.

Home Stretch™ 40 Mil Membrane Advantages

Home Stretch™ 40 Mil waterproofing membranes ensure long-lasting protection for below-grade expanded and extruded polystyrene ICF, CMU, and poured concrete walls. Home Stretch™ comes in 40 mil 36-inch wide by 66.7-foot long rolls (200 ft2 roll) with a disposable treated release liner.

Benefits and features of Home Stretch™40 Mil membrane include:

Factory-controlled manufacturing offers 40-Mil uniform and consistent thickness

Side lap design more effectively delivers water tightness

Does not produce odors and lacks V.O.C.Tee Outlets

Release film protects the adhesive layer and does not easily tear®

Extended selvage edge for asphalt-to-asphalt adhesion at the seam

Offers excellent durability, puncture resistance, and high tensile strength

Home Stretch™ Companion Products

Home Stretch™ , used our other waterproofing products

BB GF (formerly Polyguard® Blue Barrier Gap Filler), Home Stretch™ Detail Tape, Totalflow™, Polyflow®10, Totalflow™ Tee Outlet, Totalflow™ End Outlet), and 650 WB Liquid Adhesive to produce a complete and effective waterproofing system for ICF, poured concrete, and CMU, below-grade walls.

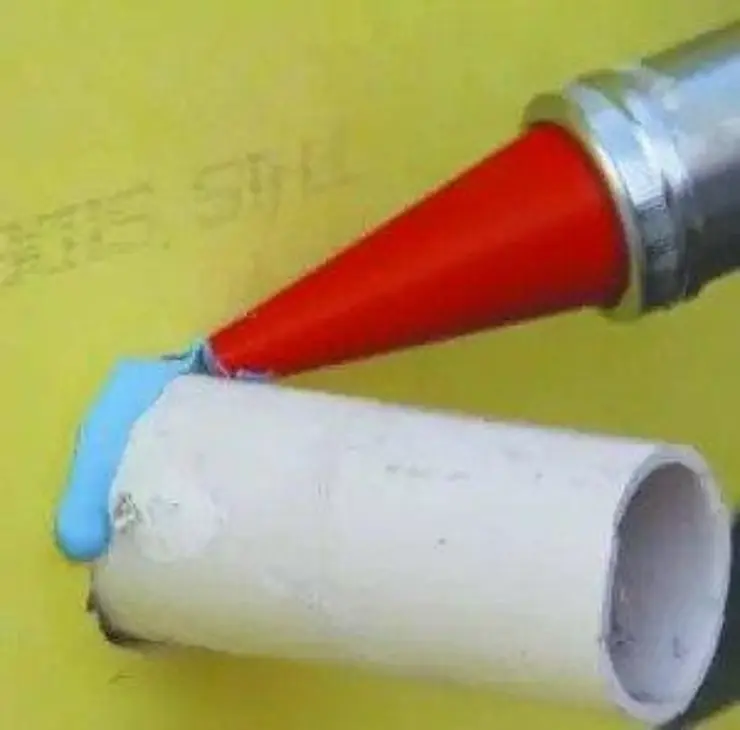

Polyguard® BB GF (formerly Blue Barrier Gap Filler)

Builders can use Polyguard® BB GF (formerly Blue Barrier™ Joint Filler) sealant and structural adhesive to caulk seams and voids and bond dissimilar products.

Home Stretch™ Detail Tape

Flexible, robust, and self-adhesive Home Stretch™ Detail Tape is made with a cross-laminated, high-density polyethylene (HDPE) backing bonded to a rubberized asphalt compound. Home Stretch™ Detail Tape can fabricate the inside and outside corners, seal penetrations, cold joints, and damaged areas of the Home Stretch™ Waterproofing Membrane.

Totalflow™ System

Prefabricated, tapered, high-capacity sheet molded Totalflow™ perimeter drainage panel, constructed using a formed polystyrene core, transitions the water collected from Polyflow® 10 to an outlet drain. The Totalflow™ ¼-inch wide top meets the Polyflow® 10, tapering to 1-inch wide at the bottom. The tapered design allows more water to move away from the structure and into the drain. Totalflow™ rests on the waterproofed footer as the first component of the Polyguard® drainage system.

Polyflow® 10

Polyflow® 10 Drain Boards create a path for below-grade water management. The factory-applied fabric allows water to flow into the drain core to assigned drainage areas while stopping soil particle movements that can clog the core. The core permits the water to flow to designated drainage exits. The design of Polyflow® 10 allows for vertical application and protection layers for Polyguard® waterproofing membranes.

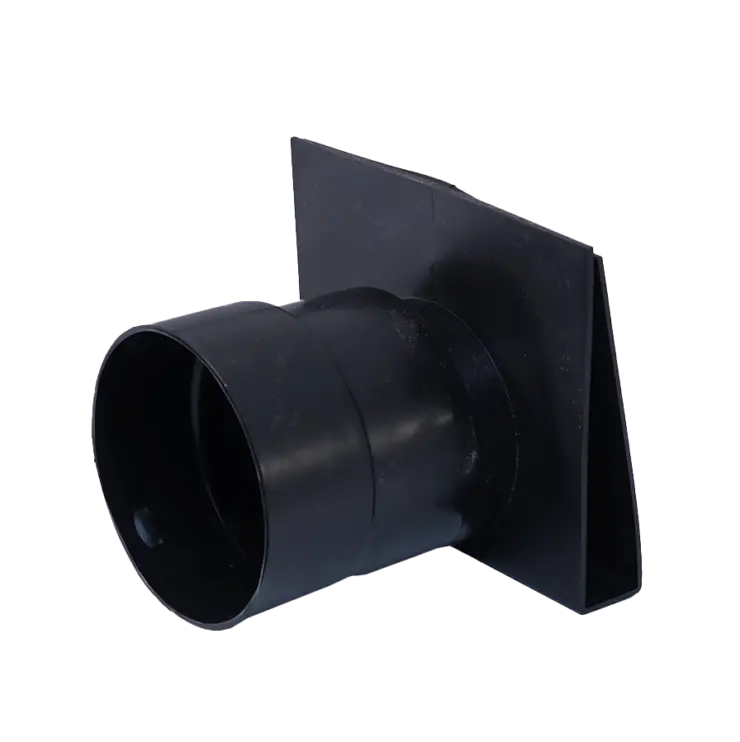

Totalflow™ Tee Outlet

The Totalflow™ Tee Outlet transitions and re-directs collected water from Totalflow™ to a hard pipe system for evacuation to daylight. It fits a standard 4-inch drain pipe. The Tee Outlet also allows connection to traditional French drainage systems.

Totalflow™ End Outlet

The Totalflow™ End Outlet transitions and re-directs collected water from Totalflow™ to a hard pipe system for evacuation to daylight. It fits a standard 4-wide drain pipe.

Home Stretch™ Water-Based Liquid Adhesive

650 WB Liquid Adhesive

Water and rubber-based, 650 WB Liquid low-tack adhesive provides excellent adhesion with all the Polyguard® waterproofing and flashing membranes under various surface conditions. The liquid adhesive applies to dry, dust- and frost-free surfaces to condition the substrate before applying Poly-Wall® Self-Adhering Membranes and Flashings. Its design allows use at ambient and rising temperatures of 40°F (5°C).

Moisture Barriers for Above-Grade ICF Construction

Insulated concrete form construction creates a more effective and higher-quality vapor and water barrier than traditional house wrap products; therefore, the above-grade walls do not require a moisture barrier. However, above-grade ICF construction does need proper flashing at the roofline, window, and doors with a high-quality product like Aluma Flash™.

Aluma Flash™

Self-adhering, self-sealing, waterproof rubberized asphalt Aluma Flash™ applies to straight window frames, door frames, and other construction seams.

Self-adhering, 20-mil thick Aluma Flash™ offers several benefits:

Polyguard® specifically designed easy-to-apply rolls of Aluma Flash™ for walls, with a simple-to-remove film release sheet.

Its self-sealing nature provides a smooth, watertight surface around staples, nails, and fasteners.

20 Mil thick aluminum-backed rubberized asphalt sheet creates an air barrier membrane

Its elastomeric properties stretch and resist cracking and tearing if structural movement occurs

Resists most chemicals

The aluminum top allows UV exposure times up to one year after application.

75 linear feet rolls of Aluma Flash™ come in 4, 6, 9, and 12-inch widths.

Solving ICF Moisture Problems with Polyguard® Products

Not adequately flashing at the roofline and openings can lead to above-grade ICF moisture problems. In addition, hydrostatic pressure and capillary action can also cause moisture problems in below-grade ICF walls. Fortunately, Polyguard® has the solution to both problems. Applying Aluma Flash™ to above-grade walls and Home Stretch™ 40 Mil Membrane to below-grade walls, and their companion products, can protect your ICF structures from moisture infiltration and the structurally damaging and unhealthy effect of mold and mildew.

Contact the professionals at Polyguard® today for more on how to solve ICF moisture problems with Polyguard® products.