Builders install through wall flashings (TWF) on the inside of above grade building envelopes to direct water away from the exterior wall system to the exterior finish layer, which is vital when using absorbent building materials like brick. TWF also prevents water from pooling along the brick's porous surfaces that can lead to costly repairs.

A through wall flashing directs the water:

From the face of the backing wall to the face of the exterior finish

From the innermost face of the structural wythe to the exterior face of the wythe

From the innermost part of a windowsill or door threshold frame in a wall assembly to the exterior face of the sill or threshold

Through Wall Flashing Material

Manufacturers design through wall flashings (TWF) for different building types, such as masonry and metal buildings. Common materials used for flashings include stainless steel and metal through wall flashing.

Problems with Metal, Galvanized Steel, or Aluminum Flashings

Problems can occur with metal flashings due to improper installation, exposure, foundation settlement, and corrosion.

Improper installation may cause the flashing to detach from the building.

Metal flashing can expand and contract due to temperature changes, which can result in warping that allows water to penetrate the building envelope.

Flashing will loosen and detach from a structure as a building's foundation settles.

To prevent galvanic corrosion and resulting holes in the flashing, builders must ensure compatibility between the metal flashing and the adjoining building materials.

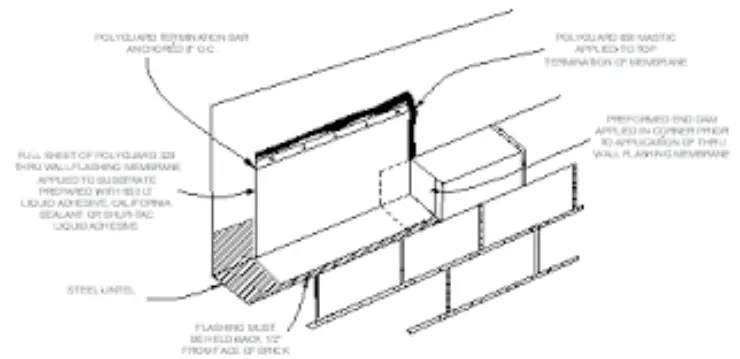

Polyguard Through Wall Flashing

Polyguard Private Brands offers a low-cost alternative material to metal TWF - Polyguard through wall flashing rubberized-asphalt membrane.

Self-sealing, fully-adhered Polyguard through wall flashing membranes apply to exterior masonry wall systems to deflect water from wall penetration, and they will not crack or corrode (like metal flashings do). Polyguard through wall flashing membranes will also maintain integrity if punctured or subjected to foundation settlement.

Through Wall Flashing Details

An effective TWF design must ensure efficient water passage to the walls' exterior layer:

Location: The flashing should rise at least 8 inches from the building's exterior low point to the higher points inside the wall where any flow of water would be interrupted.

End Dams: The end dams of a TWF collect the water from the flashing, and direct it out the weeps, similar to how a gutter's end cap directs collected water into the downspout.

Weeps: TWFs need weeps (dedicated openings) in the exterior for water passage. The weeps act like the downspout of a gutter.

Cant Strips: Installing cant strips will provide a smooth transition from vertical to horizontal planes and maintain a continuity of slope to drain to reduce ponding in areas of different elevations.

NOTE: Installing through wall flashing membranes behind siding, stucco, or other exterior finishings, makes them accessible for routine inspection and repairs. The long-term integrity and health of a building depend on adequately installed and maintained flashings. It is good to routinely check for loose or unattached through wall flashings.

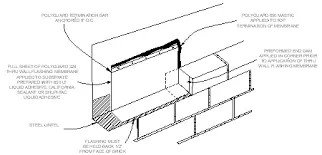

Masonry Through Wall Flashing Details

Builders should extend the flashing of a brick wythe by at least eight inches, with weeps spaced a maximum of 24 inches O.C. The Brick Institute of America (BIA) recommends using a gravel bed on top of the flashing to help prevent mortar droppings from clogging weep holes.

Where to Install Through Wall Flashings

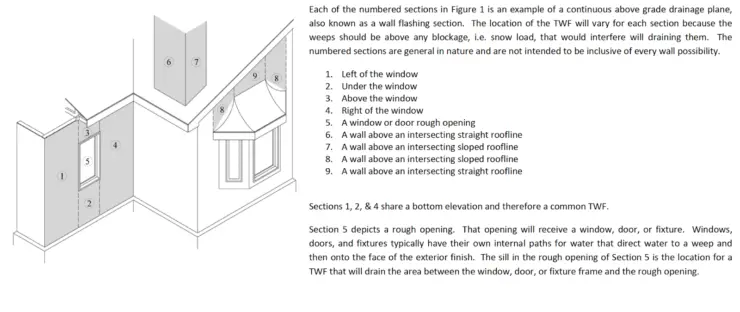

Creating a continuous above grade drainage plane (wall flashing section) involves installing TWFs on the exterior wall system in general locations. It is important that always place TWF above any blockage (i.e., snow) points that may interfere with drainage.

1. Left of the window

2. Under the window

3. Above the window

4. Right of the window

5. At windows’ or doors’ rough opening

6. At the wall above an intersecting straight roofline

7. At the wall above an intersecting sloped roofline

8. At the wall above an intersecting sloped roofline

9. At the wall above an intersecting straight roofline

Placement of TWFs must include all areas of the wall that are susceptible to moisture intrusion and will vary based on a building's design and industry standards. For help determining the optimum points to place TWFs on your building, don't hesitate to contact the Polyguard Private Brands professionals at 612-801-8476.

Polyguard Through Wall Flashings

Polyguard Private Brands offers through wall flashing (TWF) in 30 and 40-mil membranes. Builders can use the membranes for through wall flashings, window and wall flashing, joint flashing, and non-vapor permeable sheet air barriers.

The Benefits of Polyguard Through Wall Flashing

Polyguard through-wall 30 and 40 mil flashings have several features to help ensure their long-term effectiveness for deflecting water from wall penetrations in exterior masonry wall systems.

Polyguard TWF is more durable than metal flashing

Stretchable Polyguard TWF can accommodate a high degree of masonry movement compared to metal flashing.

Polyguard TWF rubberized-asphalt membranes create a firm adhesion between the surface and itself, which eliminates the cracking or corrosion experienced with metal systems.

The strength and flexibility of Polyguard TWF membranes allows builders to field cut and shape the membranes to meet various job site conditions.

Once installed and protected from ultraviolet light, the Polyguard TWF membrane will not decay or rot from mildew, mold, or plasticizer migration like metal or PVC materials.

Applying polyguard TWFs in corrosive waterproofing applications in high alkali conditions will create a permanent waterproofing system for over 25 years.

Polyguard TWF costs significantly less than fabricated metal flashings, and also saves money by eliminating the need for reglets. Builders can seal top terminations with a troweled bead of asphalt-based adhesive/sealant or detail sealant.

The Benefits of Polyguard Through Wall Flashing

Polyguard through-wall 30 and 40 mil flashings have several features to help ensure their long-term effectiveness for deflecting water from wall penetrations in exterior masonry wall systems.

Polyguard TWF is more durable than metal flashing

Stretchable Polyguard TWF can accommodate a high degree of masonry movement compared to metal flashing.

Polyguard TWF rubberized-asphalt membranes create a firm adhesion between the surface and itself, which eliminates the cracking or corrosion experienced with metal systems.

The strength and flexibility of Polyguard TWF membranes allows builders to field cut and shape the membranes to meet various job site conditions.

Once installed and protected from ultraviolet light, the Polyguard TWF membrane will not decay or rot from mildew, mold, or plasticizer migration like metal or PVC materials.

Applying polyguard TWFs in corrosive waterproofing applications in high alkali conditions will create a permanent waterproofing system for over 25 years.

Polyguard TWF costs significantly less than fabricated metal flashings, and also saves money by eliminating the need for reglets. Builders can seal top terminations with a troweled bead of asphalt-based adhesive/sealant or detail sealant.

Why Use Polyguard Through Wall Flashings?

Installing Polyguard through-wall flashings inside the above grade building envelope will effectively and cost-efficiently direct water away from the exterior wall system.Polyguard through wall flashings are both flexible and strong in order to better protect a building’s long-term integrity than metal flashings.

For more on effective TWF, contact the Polyguard Private Brands professionals at 612-801-8476 or email pdoud@polyguard.com.