Properly installing air ducts, including ductwork insulation when necessary, will help maintain efficient airflow. Efficient airflow promotes a comfortable indoor temperature and enhances the occupants' mental and physical health. Poorly installed ducts will leak and can lose 20 to 30 percent of the air flowing through them, which can result in high utility bills and reduced comfort levels.

When is Insulation Required on Air Ducts?

The need for air duct insulation depends on the climate and the ducts’ location relative to the building:

- Duct systems located outside or in unconditioned indoor spaces, like attics and crawl spaces, require air duct insulation, and are vital in cold and humid climes to prevent condensation, which can lead to unhealthy mold and damaging corrosion.

- Ducts in a basement ceiling or between floors require insulation to avoid condensation, which can leave water stains on the below ceilings.

- Duct joints require insulation because they are more susceptible to leakage.

IMPORTANT: Local and state codes may require stricter insulation fire codes in crawl spaces; therefore, always check with local and state building officials on codes before installing duct insulation in a crawl space.

In addition, before applying air duct insulation, check the ductwork for the presence of an insulated lining (installed during its fabrication process) by removing the filter from the furnace’s filter box and shining a flashlight inside the ducts. Bare metal indicates uninsulated ducts.

The Benefits of Ductwork Insulation

Ductwork insulation provides numerous benefits that save money and improve indoor environmental quality (IEQ):

- Enhances the efficiency of the air duct system, which lowers energy bills

- Prevents wear and tear on the ductwork, which reduces maintenance costs and protects its integrity

- Protects the air ducts from dust particles and bacteria, which makes it easier to maintain and clean ductwork

- Reduces noise, which improves IEQ

- Minimize or prevent air leakage and condensation, which improves indoor air quality.

- Improves airflow inside the air ducts, which creates a more comfortable indoor temperature

- Enhances safety by minimizing the risk of combustion gasses (like carbon monoxide) coming from gas appliances and back drafting into living spaces

Protecting Exterior Insulated Ductwork with Polyguard Weather-Proofing Jackets

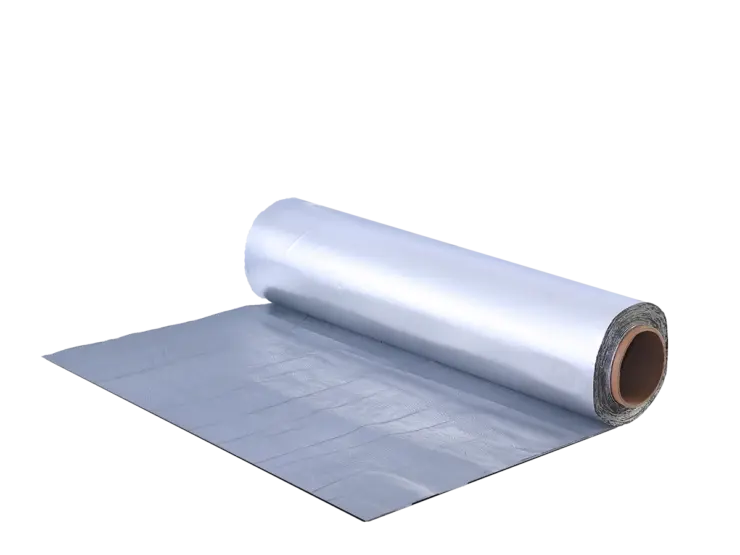

Appling a Polyguard Alumaguard® self-adhering peel and stick zero-perm, flexible, weather-proof claddings over the air duct insulation provides several vital benefits:

- Protects the insulation from damaging water

- Helps preserve the insulation’s efficiency and integrity

- Reduces energy costs

- Acts as a vapor retarder to prevent moisture migration to the duct's service

Polyguard offers self-healing rubberized bitumen and acrylic adhesion systems for all-weather installations. Polyguard Alumaguard® products all carry a 10-year warranty and include Alumaguard® All-Weather, Alumaguard®, and Alumaguard® Lite.

Alumaguard® All Weather

Polyguard's Alumaguard® All-Weather weather-proofing cladding offers the only flexible insulation cladding in today's market.

Alumaguard® All-Weather protects ductwork from moisture, air, and vapor infiltration. It combines rubberized asphalt self-healing features with straightforward application and the cold-weather performance of acrylic adhesive-based materials.

Companion Products:

Alumaguard® Air Release Valves on the duct's bottom furnish a one-way air pressure release related to stress under the duct's bottom.

Alumaguard® Lite installed on the underside of the duct removes the need for pinning.

Alumaguard® Self-Healing Membrane

Foil-faced, flexible, zero perms, and self-healing Alumaguard® provides exterior air ducts superior weather, vapor, and UV protection, with excellent emissivity properties and sound attenuation.

Composite Alumaguard® is a quick peel-and-stick installation that does not require any special tools. However, when installing Alumaguard® to rooftop ductwork, the rooftop's slope must stop ponding water.

Alumaguard® Lite

Lightweight, durable, puncture-resistant UV-resistant, zero-perm Alumaguard® Lite weather barrier membrane applies to exterior insulated ductwork that is not prone to physical abuse, but needs a zero-perm vapor barrier.

Alumaguard® Cool Wrap™

Alumaguard® Cool Wrap™ offers a flexible, energy-saving cladding in configurations for all Alumaguard® family products. Cool Wrap™ technologies include:

- A matte white finish

- Solar reflectance

- Qualifies for LEED credits

Alumaguard® Lite Cool Wrap™

Sustainable Alumaguard® Lite Cool Wrap™ offers a matte white, high emissivity/reflectivity coated membrane. It qualifies for LEED credits and meets the requirements for emissivity and solar reflectance. The Alumaguard® Lite Cool Wrap™ acrylic adhesive is an eco-friendly zero perm weather and vapor barrier.

Insulation Requirements for Air Ducts

The need for air duct insulation depends on the climate and location. In general, ducts in unconditioned and exterior spaces, duct joints, and ducts installed between a building’s floors require air duct insulation. Polyguard suggests you check with your local and state building offices for specific codes and mandates for air duct insulation.

Ductwork insulation can save money through reduced energy, maintenance, and replacement costs. It also improves IEQ by creating more comfortable indoor temperatures, improving air quality, and reducing noise. In addition, installing waterproofing products, like Polyguard's Alumaguard® Family of Cladding Products, over air duct insulation will preserve its integrity and efficiency, lower energy costs, and prevent moisture infiltration into the duct system, which leads to condensation, mold, and corrosion.

For more on when to apply air duct insulation, contact our experts at Polyguard today!