Pipeline systems are indispensable for the efficient transportation of resources across vast networks. However, these infrastructures face significant threats, including AC induced corrosion—a specific type of electrochemical degradation that can weaken pipelines over time.

This article explores the mechanisms of AC corrosion, its challenges for pipeline operators, and practical strategies to mitigate its impact.

What is AC Induced Pipeline Corrosion?

AC induced corrosion occurs when alternating current (AC) from nearby electrical infrastructure, such as high-voltage power lines, interacts with metallic pipelines. This interference creates localized currents on pipeline surfaces, accelerating metal loss in areas where coatings are compromised. Unlike traditional corrosion caused by direct current (DC) electrochemical reactions, AC induced corrosion introduces unique risks that require specialized prevention methods.

Factors Contributing to AC Corrosion

Several factors increase the likelihood and severity of AC induced corrosion:

- Proximity to Electrical Infrastructure: Pipelines located near high-voltage lines are more exposed to AC interference, heightening their vulnerability.

- Soil Conditions: Low-resistivity soils provide a conductive environment, intensifying corrosion rates.

- Coating Defects: Small imperfections in coatings can allow current concentration, exposing underlying metals to rapid deterioration.

Identifying these contributing factors early helps operators take proactive measures to reduce risks and extend pipeline longevity.

How AC Interference Weakens Cathodic Protection

While cathodic protection (CP) is widely used to safeguard pipelines, its effectiveness can be significantly compromised by the presence of AC interference.

Challenges to Cathodic Protection Systems

AC interference disrupts the protective electric potential that CP systems provide, reducing their ability to shield pipelines effectively. This can lead to localized corrosion at coating defects. For example, AC-induced polarization can alter the electrochemical balance of protected pipelines, leaving exposed areas more vulnerable to accelerated degradation.

Accelerated Corrosion in High-AC Environments

Pipelines in close proximity to high-voltage power lines often experience rapid corrosion. For instance, studies indicate that significant metal loss can occur within two years in areas with sustained AC interference. Without additional mitigation measures, these environments present persistent risks to pipeline integrity.

With these challenges in mind, identifying and monitoring areas of high-risk interference becomes the next critical step.

Identifying and Assessing AC Induced Corrosion Risks

Accurate detection and assessment of AC induced corrosion are fundamental to identifying risks and implementing effective prevention strategies.

Monitoring Techniques

Effective detection begins with targeted monitoring efforts:

- AC Voltage Surveys: Regularly measuring AC voltage along pipeline routes helps identify high-risk areas, typically where AC potential exceeds 15 volts.

- Corrosion Probes: These devices measure current density on pipeline surfaces, providing valuable data on corrosion activity in affected zones.

- Continuous Monitoring Systems: Real-time monitoring devices now include automated alerts, enabling operators to respond swiftly to interference.

Advancements in AC Monitoring Technology

Recent innovations in AC monitoring technology further enhance detection capabilities. Modern systems incorporate predictive modeling tools that offer insights into how AC interference may evolve, allowing for proactive adjustments to cathodic protection systems. By leveraging real-time data analysis and predictive capabilities, operators can address potential issues before they escalate into costly damage.

By combining traditional monitoring methods with advanced technologies, pipeline operators can minimize risks more effectively, ensuring the long-term safety and reliability of their infrastructure. Clear and precise detection processes are the foundation for implementing targeted and effective mitigation strategies.

Comprehensive Strategies to Combat AC Induced Corrosion

Implementing prevention and mitigation strategies is essential to address the multifaceted challenges posed by AC induced corrosion.

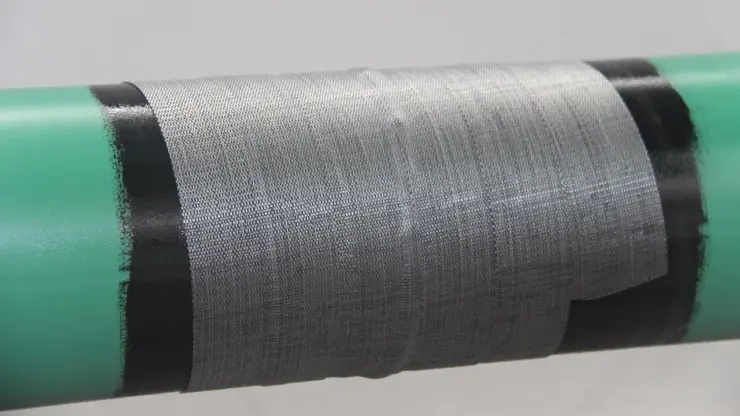

Coating Solutions

A strong coating system is the first line of defense against AC induced corrosion. Polyguard’s RD-6® Coating Systems provide an advanced solution by delivering a durable, defect-resistant barrier. These coatings are engineered to adhere firmly to pipeline surfaces and resist the damaging effects of AC interference, even in challenging conditions. For instance, RD-6® is specifically designed to maintain adhesion on pipelines exposed to high thermal stress and fluctuating temperatures, ensuring long-lasting protection where traditional coatings may fail.

Improving Cathodic Protection

Optimizing CP systems with supplementary tools enhances their effectiveness in high-AC environments:

- Gradient Control Mats: These mats safely dissipate AC currents into the ground, reducing interference at the pipeline surface.

- Zinc Ribbon Anodes: These anodes divert corrosive currents away from the pipeline, ensuring greater protection for exposed areas.

- Decouplers: Devices that separate AC currents from CP systems while maintaining DC continuity improve the overall efficiency of protective measures.

Strategic Pipeline Design

Careful planning during the design phase reduces exposure to AC interference:

- Route Optimization: Positioning pipelines at safe distances from high-voltage infrastructure limits AC exposure.

- Grounding Systems: Installing grounding beds at strategic points disperses stray currents, protecting the pipeline from prolonged exposure to interference.

With these strategies in place, operators can ensure long-term protection and reliability, further strengthened by Polyguard's advanced solutions.

Safeguard Your Pipelines with Polyguard's Expertise

Polyguard is a leader in pipeline protection, offering innovative solutions tailored to the most demanding conditions. Our expertise in addressing AC induced corrosion ensures pipeline systems remain operational, secure, and efficient. Learn how our advanced tools and techniques can fortify your pipeline systems against even the most challenging environments.

Contact us today for more information.