In a residential home, corroded pipes are a serious problem. In commercial and industrial applications, pipeline corrosion is a nightmare. Pipeline corrosion occurs when old metal pipes rust from exposure to water or moisture from the environment. Corroded pipelines can damage the quality of whatever they’re carrying, from water to oil. When pipelines are damaged by corrosion, they eventually break down and wear out, or can even burst.

Industrial coatings are one of the best methods of prevention of pipe corrosion. Coatings and linings can be used on pipes that are above ground, submerged, or buried underground. The longevity of a pipeline has to do with several factors, including the type of materials the pipe is made of, how and where it is installed, maintenance needs, and whether pipe corrosion protection measures were used.

Pipelines that are damaged can lead to leaks or ruptures. While leaks and ruptures are often caused by natural forces (the earth shifting underneath them in earthquake-prone areas, for instance), improper materials, poor welding of seams, and environmental exposure can all be contributing factors. However, the damage can be mitigated by using pipeline corrosion protection.

Causes of Pipeline Corrosion

Pipeline corrosion can be caused by a number of environmental factors — pH of the water or soil, temperature of the water or air, minerals in the water, exposure to sunlight. The material the pipeline is carrying (oil, gas, fertilizer, compressed air, non-revenue water, waste, etc.) can also contribute to corrosion. An abundance of oxygen in the water will degrade metal through oxidation. Atmospheric corrosion caused by contact between metal and moist air can occur in above-ground conditions but is more prevalent in underground environments; the majority of pipelines in the U.S. are buried underground.

Above-ground pipelines can be subject to damage from pitting, which can be caused by constant blasting by sand grains, among other things. Metal is strong, but it is not impervious, and many factors can slowly erode the metal’s structural integrity. Protection of a pipeline through coatings can mitigate all of these concerns. Once a source of corrosion has been dealt with, either through a coating or other chemical inhibitor, it is considered non-active corrosion — this means the corrosion process has been stopped.

Pipeline Corrosion Protection Products

Steel is the primary material used for hazardous liquid pipelines. Gas distribution pipelines are typically constructed of steel or high strength plastic or composites.

Prevention is key when it comes to properly maintaining pipes. Pipe corrosion protection starts with cathodic protection, corrosion inhibitors, and exterior industrial coatings.

Cathodic protection uses an electrical current to allow another metal to provide protection instead of the steel pipeline. Corrosion inhibitors are substances that can be added as internal protection in the pipeline.

Polyguard IRO & Polyguard IRO HD

Polyguard makes two pipe corrosion protection products that are designed to protect field joint coatings and mainline coatings from abrasion damage which might occur due to backfilling, drilling, or other conditions. Polyguard IRO & IRO HD products create an outer, sacrificial layer that is allowed to abrade so that the pipeline material doesn’t erode. IRO stands for Impact Resistant Outerwrap and HD stands for Heavy Duty. The IRO consists of a strong fiberglass wrap that is impregnated with a water-activated resin that hardens in minutes. Polyguard IRO HD is a heavy-duty version of its original IRO pipeline corrosion protection product.

For field-approved coatings that are used on pipeline joints and other coatings, IRO & IRO HD both provide real mechanical protection for the underlying material. This coating can be efficiently applied in any project environment and can be applied over Polyguard’s coatings such as RD-6, epoxy products, or RG-2400 gel corrosion inhibitors. Anchoring of the IRO or IRO-HD requires only a roughened surface. Polyguard IRO is proven to work in conjunction with a cathodic protection system, so it can be utilized in accordance with DOT and PHMSA codes.

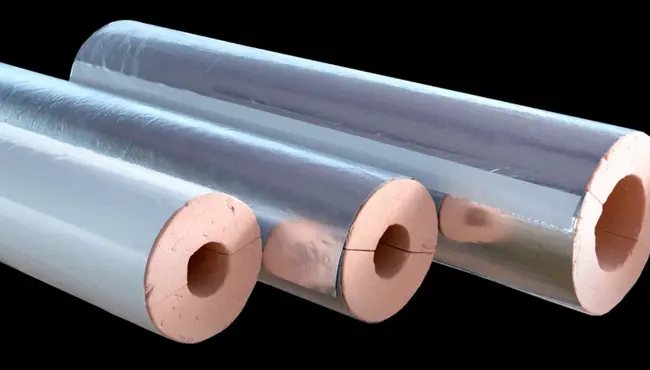

Polyguard ZEROPERM

Polyguard ZEROPERM is one of several vapor barriers the company makes. ZEROPERM is a 3-ply composite membrane consisting of a white 0.5 mil polyester film, 1.0 mil aluminum foil, and one 0.5 mil clear polyester film. It is reversible, with white on one side, and silver on the other. The foil provides zero permeance in the composite while the tough and tear-resistant polyester layers protect the foil.

The jacket protector option is used either between layers of insulation on sub-freezing projects like LNG pipelines, or as the outer vapor-barrier jacket on ammonia, brine or glycol pipelines. ZEROPERM can also be installed in the field. There are two types of ZEROPERM tape which adhere with a high-quality acrylic adhesive to complete the installation, both with excellent cold weather performance. ZEROPERM A Tape has a kraft release liner and is typically used for sealing longitudinal and circumferential laps. ZEROPERM Self-Wound Tape has no liner and is used on valves and fittings.

Polyguard RD-6 Coating System

Coatings are one of the primary means of protection for a pipeline. Polyguard’s RD-6 pipe corrosion protection is a coating system that is used on buried and submerged pipelines. Once a UV-protective coating such as RD-6 UV Overcoat is used in conjunction with RD-6, it can be used above ground. For pipelines that carry materials reaching 190° F (88° C), a heat-protective high-temperature coating system such as Polyguard’s RD-6 HT is suitable.

The RD-6 Coating System consists of a liquid adhesive, a geotextile backed protective pipeline coating, and a tightly woven, polypropylene geotextile fabric outerwrap. The system provides pipeline corrosion protection through the polymer modified outer coating layer. RD-6 has been used on thousands of projects for over 30 years. It is impervious to external corrosion and stress corrosion cracking (SCC), which occurs when a corrosive environment and tensile stress combine to create a weak point.

With the RD-6 coating system, the cathodic protection current can still reach the sacrificial layer. The geotextile backing used with RD-6 HT has extremely high breaking strength, low elongation, and high temperature resistance. RD-6 HT is fast, easy to apply, and can be backfilled immediately after coating.

Polyguard VaporGuard Butyl Tape

Provide freeze-thaw and other cold temperature protection for a pipeline with Polyguard VaporGuard Butyl Tape. Butyl tape is a non-curing elastomer developed for use as a vapor stop on sub-freezing insulation systems. It remains flexible down to -20º F, and can be used on terminations, in-line vapor stops, and expansion joints. The tape easily presses into place once the paper backing is removed.

VaporGuard prevents moisture from entering along insulation systems, which protects the pipe from rust and corrosion, while also protecting it from freezing temperature damage, and freeze-thaw damage. VaporGuard is available in two convenient sizes: 1-1/4″ x 100′ or 12″ x 40′.

Polyguard RG-2400

One of the other primary methods for prevention of pipeline corrosion is a corrosion inhibitor, such as Polyguard RG-2400 Corrosion Control Gel. Even when a pipe is wrapped with insulation, pipes can begin to show leaks. RG-2400 was developed to prevent CUI, or corrosion under insulation in food processing, beverage, and other industries which use ammonia refrigeration systems.

RG-2400 AK gel is a hand-applied formulation that can withstand application to pipes with a surface temperature up to 250° F (121° C). It will not harden or set up over time. Its color provides an easy method to tell when it is applied correctly — when you can no longer see the pipe through the purple gel, you should have sufficient coverage.

Another way to take the guesswork out of your pipe corrosion protection system is by using the Polyguard AccuTrowel. It is a hand-held metering trowel tool set that accurately determines mil thicknesses when applying viscous coatings to pipe surfaces. AccuTrowel ranges from 2″ to 12″ and is manually operated to make sure your pipe coverage is precise. The trowel allows you to save material costs by removing any excess gel.

Protecting Your Pipeline

Pipe corrosion protection begins with coatings and ends with outer wraps that protect the pipes as well as the coatings themselves. Polyguard products meet both of these goals for pipeline corrosion protection from the inside out, in cold weather or hot, and in any environment, whatever the pipe is carrying.

Interested in discussing your options for pipeline protection? Contact Polyguard’s Pipeline Division today for expert insights.