Underseal® Blindside™ Membrane

Overview

(Formerly 751)

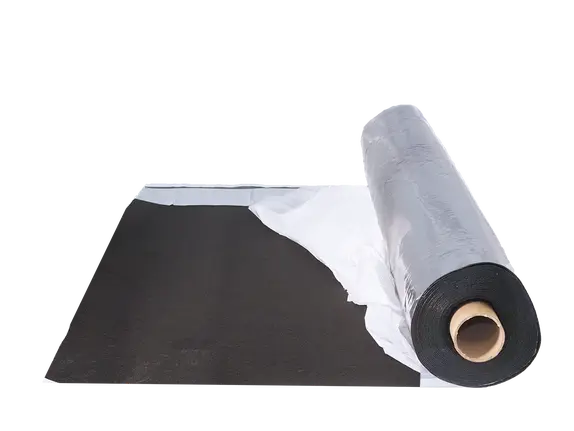

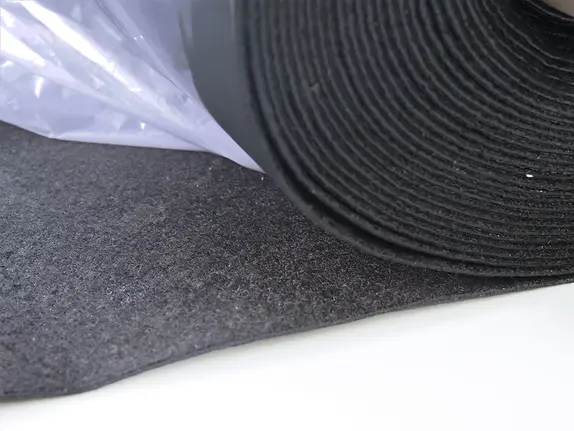

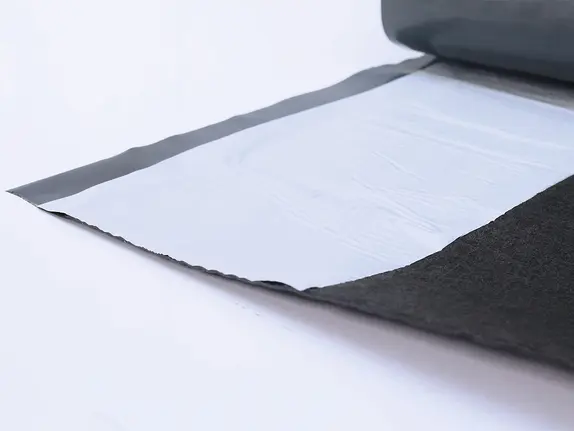

Blindside Membrane is a tough, 73-mil pre-concrete pour waterproofing membrane/vapor barrier designed to virtually eliminate water and vapor transmission through below grade concrete walls.

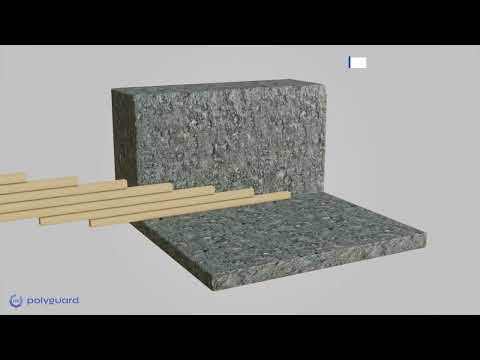

Blindside Membrane is used as a waterproofing membrane where vertical, positive-side waterproofing is required to be installed before the foundation walls are poured. A strong mechanical bond is developed between the membrane and concrete at the time of pouring as the concrete intermingles with the fibers of the nonwoven geotextile. A strong adhesive bond is created when the static load and thermal reactive heat of the concrete slab causes sealant/adhesive compound to have an intimate contact with the concrete surface preventing water migration. With both a mechanical and adhesive bond, the concrete will be tightly sealed and bonded to the membrane, creating superior protection against moisture intrusion. 73-mil Blindside can also be used in certain horizontal applications. Contact Polyguard for more information.

Companion Products

Product Resources

- Architectural

- Detail(s)

- Architectural

- Detail(s)

- Architectural

- ICC-ES Evaluation Report 5580

Best Sellers

Explore our articles to learn more about products in application.