Builders place wood sill plates on top of the foundation wall to keep the building's exterior joist, studs, and floor level. Unfortunately, exposure to moisture and termites at the joint between the concrete and sill plate can cause wood rot and structural damage.

To create a tight seal and protect the building's integrity, the builder should apply the best sealant between concrete and wood at the three likely access points of the sill plate:

- Sill Plate: an application of a quality sill plate sealer, like TERM® Sill Plate Barrier or synthetic rubber

- Outside Gap: sealing the outside where the framing meets the foundation with Polyguard BB GF

- Inside Gap: sealing inside where the framing meets the foundation with Polyguard Gap Filler

NOTE: Only use pressure-treated lumber for the framing since concrete tends to wick moisture from the ground.

Why Air Seal at the Framing Stage?

Adequating air sealing at the framing stage will protect a building's integrity and create a more comfortable and safe indoor environment. Several significant reasons to air seal at the foundation and framing joint include:

- Helping to keep up with the evolving energy codes that demand tighter building envelopes

- Limiting outdoor air from infiltrating inside, to prevent it from bringing outdoor contaminants like pollen, pollution, mold spores, etc.

- Allowing a tremendous amount of moisture to deposit within the wall cavity, which can lead to condensation and structurally damaged and unhealthy mold

- Sealing at the framing stage to help keep insects and other critters from setting up house inside your walls

Creating an Airtight Seal Between Foundation and Framing

The joint between the foundation and framing includes three openings that air, moisture, and pests can infiltrate. Therefore, effectively sealing the joint must address all three gaps.

Apply a Quality Sill Sealer

Builders often use a foam sill seal between the foundation and framing. It does a good job as a capillary break, and forms an air seal as the weight of the framing crushes the foam. This method only works effectively on smooth-topped foundations. Rough-topped foundations will produce uneven gaps under the sill plate.

A Better Sill Sealer - Synthetic Rubber

Applying a synthetic plastic gasket with two neoprene bulbs at the base of the wall provides a much more effective air seal than foam. The bulbs will crush down between the framing and concrete, to create an exceptionally tight air seal between the foundation and framing.

The Best Sill Sealer - TERM Sill Plate Barrier

The TERM Sill Plate Barrier prevents moisture and pests from accessing wood framing through concrete cracks or joints in the floor.

TERM Sill Plate Barrier installed underneath the sill plate offers several advantages:

- Provides a full vapor and waterproofing barrier for wood framing against moisture from the concrete

- Blocks moisture and air from the exterior and energy leaks from the interior contribute to a tight building envelope

- Is a non-chemical barrier to subterranean termites

- Prevents foraging insects, like cockroaches and ants and from entering gaps between the sill plate and unlevel slabs

Seal the Outside and Inside Gaps Between the Foundation and Framing

A quilty fluid-applied flashing, like Polyguard BB GF, is a straightforward way to seal effectively the joints connecting the framing to the foundation, compared to taping methods. Wax, concrete additives, oils, and moisture can affect the bonding of sealing tape to the concrete and framing.

Fluid-applied sealants offer several benefits to a home's performance:

- Forms a rubber barrier to the home's interior and exterior base

- Protects the vulnerable bottom edge of the wood sheathing against splash-back

- Gives a place to shingle your weather barrier over later

Polyguard Blue Barrier Gap Filler

Permeable Polyguard Blue Barrier Gap Filler is a structural adhesive and detail sealant that is used to fill gaps and bond dissimilar materials like concrete and wood. Builders can use Gap Filler2200 to seal the interior and exterior gaps between the foundation and framing. In addition, you can use Gap Filler to prepare surfaces before applying other Polyguard products for air barriers and flashings.

Polyguard engineered GF uses Silyl Terminated Polyether (STPE) Technology. It comes in 20 oz. sausages or 10 oz. caulking tubes.

Benefits of Polyguard BB GF

- Superior shore hardness to prevent filler wear and tear

- Large joint and seam filler to bridge gaps up to 3/4-inch on multiple substrates

- Class A surface burning rated to provide added fire protection against flame spread and smoke development

- Environmentally friendly, Solvent-free, isocyanate-free, and low VOC

- Exceptional adhesion: Bonds well to select substrates, including gypsum, ICF, CMU block, concrete, and (untreated) OSB or plywood sheathings

- Non-sag to create a better and cleaner application bead

- Biological growth resistance: Does not provide a food source for biological growth, such as mold

- Advanced proprietary technology to provide superior adhesion

- Wet surface applications: Bonds and cures over damp wall substrates clear of detectable surface water, frost, ice, or snow

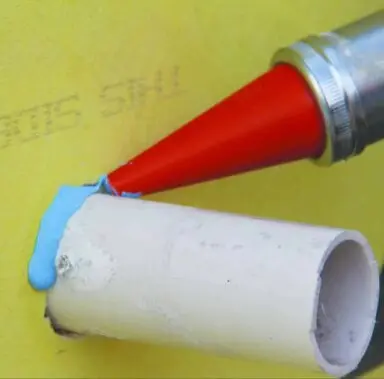

Applying Polyguard BB GF

You can simply and quickly apply Polyguard BB GF over dry and damp surfaces:

- Clean the surface with a brush, to ensure a dust, debris, coatings, and membrane-free surface.

- Apply the filler using a sausage gun with an applicable tip to achieve the desired bead of material.

- Spread to even out using a plastic putty knife.

- Allow a minimum of four hours to set/cure.

Choosing the Best Sealant Between Concrete and Wood

Selecting the best sealant between concrete and wood in order to seal the space between the foundation and wood framing will contribute towards a tight building envelope, help meet modern energy codes, limit damaging condensation in the wall cavity, and stop pests from entering the wall system. Adequately sealing the space between the concrete and wood must include an application of a quality sill plate sealer, like TERM® Sill Plate Barrier, and a quality fluid-applied flashing for the interior and exterior joints, like Polyguard Blue Barrier Gap Filler.

Contact our Polyguard professionals today for more information on the best sealant between concrete and wood!