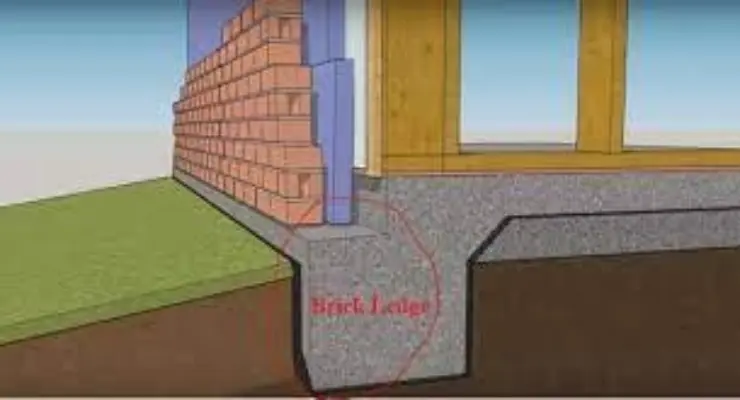

Brick ledge flashing protects against bulk water infiltration at the joint where the concrete ledge of the foundation meets the wood framing.

Brick ledge flashings also prevent the brick or masonry siding and trim from directly butting up against the concrete foundation.

Applying house wrap over the wood framing without using brick ledge flashing will not sufficiently protect your structure against bulk water. Brick ledge flashing takes water that hits the wall and kicks it out towards the exterior, to prevent accumulation within the wall system. A high-performing brick ledge flashing, like TERM Flashing Moisture | Termite Barrier also protects against pest intrusion.

Why Apply Brick Ledge Flashing?

Correctly applying a high-quality brick ledge flashing can prevent costly structural damage and poor indoor air quality by:

- Stopping water intrusion where the wall meets the foundation, to help prevent structurally damaging and unhealthy mold

- Limiting water vapor from condensing inside the masonry's surface and cores

- Minimizing infiltration of bulk water to a building's interior, which can lead to considerable damage to its contents

- Stopping infiltration of moisture into the masonry, which can freeze, causing the masonry or mortar to crack and spall

- Preventing infiltration of pests, like termites

TERM Flashing Moisture | Termite Barrier

Polyguard TERM Flashing Moisture | Termite Barrier, part of the Polyguard TERM Barrier Systems Division non-chemical termite barrier system, provides energy sealing, waterproofing, and insect resistance. Building owners can apply TERM Flashing Moisture | Termite Barrier, where the horizontal concrete brick ledge intersects with exterior wood sheathing, a frequent insect entry spot.

TERM Flashing Moisture | Termite Barrier provides the following benefits and features:

- Strong, pliable, self-adhesive TERM Flashing Moisture | Termite Barrier sheets consist of 4-mil high-density polyethylene film bonded to 36 mils of sealant

- Formulation of TERM Flashing Moisture | Termite Barrier allows for low-temperature application down to 30 ℉ (-1℃)

- TERM FUV Flashing Moisture | Termite Barrier offers 12-month ultraviolet resistance

- A flexible membrane that keeps air, moisture, and pests excluded when adequately installed as part of the building envelope

- A strong, pliable, self-adhesive sheet flashing with special silver foil facing

- 40-mils thick: 4-mil high-density polyethylene film bonded to 64 mils of sealant

- For flashing applications, Polyguard TERM Flashing Moisture | Termite Barrier comes in 12-inch and 18-inch, 75-feet long rolls and winds on a disposable treated release sheet

- NFPA 285 rated

- The only physical termite barrier with 21 years of testing and an evaluation report by the ICC (International Code Council) AC 380 ESR 3632

Applying the TERM Flashing Moisture | Termite Barrier

Temperature Restrictions: Apply TERM Flashing Moisture | Termite Barrier in temperatures above 30°F (-1°C) and greater. Wet and cold conditions can hinder adhesion; however, applying 650 LT Liquid Adhesive (designed for applications down to 25°F (-4°C)) will aid in adhesion.

- Before applying TERM Flashing Moisture | Termite Barrier, clean all dust, dirt, etc., and remove sharp protrusions. The tape's adhesive surface should not touch caulks or sealants (including most polyurethane and silicone) that contain solvents or plasticizers

- Prime the dry surfaces that you need to apply the TERM Flashing Moisture| Termite Barrier on with 650 LT Liquid Adhesive at an average rate of 250-350 ft.2/gallon by brush or roller. Wait for 30 to 60 minutes after applying primer, before placing flashing on the ledge.

- Cut pieces of flashing to the needed length.

- Place the flashing with its horizontal portion extending no closer than ½-inch from the edge of the horizontal ledge.

- Remove the release liner's first 6-12 inches and adhere the exposed adhesive face to the brick ledge.

- Overlap the adjacent flashing pieces by at least 2 inches. Shingle the pieces vertically so the piece closest to the exterior (lower piece) overlaps the other piece.

- Extend the flashing past the TERM Sill Barrier edge to ensure tie-in.

- Roll the flashing securely into place with a hand roller.

- Use 650 Mastic to seal all top horizontal terminating edges on walls, pipes, and other protrusions.

Polyguard Brick Ledge Flashings

Strong, flexible, self-adhesive sheet Polyguard TERM Flashing Moisture | Termite Barrier brick ledge flashings efficiently protects the joint between the concrete ledge and wood framing to direct water down and away from a building, which is critical to maintaining a building's health and integrity.

Contact the Polyguard professionals today for more on understanding brick ledge flashing!