Insulating HVAC ductwork is central to reducing energy waste and preventing costly moisture damage. When ducts are left exposed, they leak conditioned air into attics, basements, or crawlspaces. Properly installed materials show how to insulate ductwork in ways that preserve performance and reduce system strain.

Why Uninsulated Ducts Waste Energy and Create Moisture Risks

Most metal ducts are made from galvanized steel or aluminum, which transfer heat rapidly. Uninsulated duct surfaces lose heat in winter and absorb heat in summer. These temperature shifts reduce system efficiency and increase energy use.

- In humid environments, cold air moving through unwrapped ducts can trigger condensation.

- Surface dampness may contribute to microbial growth or corrosion over time.

- Proper insulation prevents these issues by stabilizing duct surface temperatures.

Air leaks add another layer of inefficiency. Gaps at seams, joints, and transitions allow conditioned air to escape. Running the HVAC fan and feeling along seams can help identify unnoticed leaks before sealing. That loss forces HVAC systems to run longer to meet demand. Sealing ducts can improve HVAC efficiency by approximately 15%, cutting energy waste and lowering utility costs. Leaks can also pull in dirty air from crawlspaces or attics, impacting indoor air quality.

Preparation Comes First: Inspection and Surface Cleanup

Effective ductwork insulation begins with a clean surface.

- Oil, dust, and moisture must be removed before any insulation or adhesive is applied.

- Installers should also remove degraded tape or failed wrap materials.

- Basic tools like a utility knife, foil tape, and safety gloves should be on hand before starting.

Once the surface is clean and dry, all joints and seams should be sealed. To meet building code and HVAC standards, this step requires a UL 181–rated foil tape or mastic designed specifically for duct air sealing. High-performance insulation wraps—like those from Polyguard—should only be applied after this sealing step to maintain full system efficiency and moisture resistance. These wraps work best when paired with approved duct sealants that ensure joints stay airtight over time.

Choosing the Right Insulation for Ductwork Applications

Material selection depends on duct layout, temperature exposure, and code requirements. R-6 insulation is typical for residential use. In commercial or unconditioned spaces, R-8 or higher may be necessary to prevent temperature drift.

Contractors looking at how to insulate ductwork in mixed environments—such as buildings with both interior and rooftop runs—should evaluate wrap flexibility, moisture control, and fire ratings to match each zone's demands.

Common Insulation Types and Their Use Cases

Each type of insulation has its benefits, depending on layout and access.

- Fiberglass wrap is widely used for long, straight duct runs. Its thermal resistance and availability make it a practical choice for attic or basement installations.

- Foam board works well in narrow spaces, especially with rectangular ducts. Its rigid profile provides strong thermal protection, but it may need careful sealing at corners.

- Elastomeric insulation is flexible and continuous. It wraps around curves and tight spaces with fewer seams. This option is especially useful in vibration-prone areas or when ducts run near mechanical equipment.

Once the insulation material is selected, the next consideration is how much thermal resistance—measured as R-value—is needed for your region.

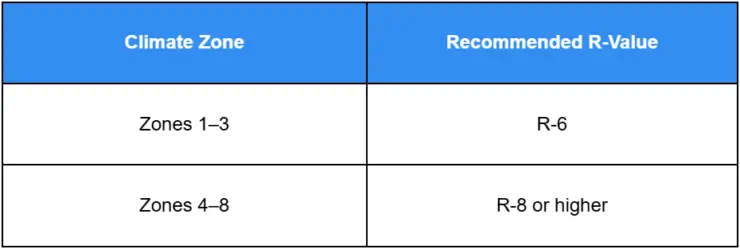

Climate-Based R-Value Guidance

Insulation requirements vary by zone. This guide shows typical recommendations based on regional climate conditions:

Following IECC guidelines helps maintain compliance and thermal efficiency in both residential and commercial builds.

Installation Sequence: Seal First, Then Wrap

1. Sealing must always occur before insulation is applied. Even a high-R-value material won’t prevent energy loss if the duct leaks. Foil tape or mastic should be applied to every joint, seam, and termination point.

2. After sealing, installers can measure and cut insulation to size. All seams should overlap and be sealed again with tape designed for insulation facings. Avoid compressing the material, which reduces its R-value.

- This is a foundational step in insulating ductwork properly to achieve energy and moisture performance goals.

- In tight areas, installers should trim insulation carefully around hangers or transitions. The wrap should remain continuous to prevent moisture intrusion. Where ducts connect to HVAC units, insulation must be sealed without blocking access panels.

3. Use a jobsite checklist to confirm all seams, wrap overlaps, and terminations are sealed and continuous.

How to Insulate Ductwork in Challenging Areas

Attics, crawlspaces, and drop ceilings often complicate insulation work. These areas may have limited access or environmental hazards. Dust, humidity, and extreme temperatures require durable, field-tested materials.

In commercial retrofits with drop ceilings or mechanical rooms, insulation access may be restricted by panels, fire dampers, or utility obstructions. Installers may need to insulate sections in stages or use materials that can be cut and sealed in place.

Return lines often carry air closer to ambient temperature. Sealing and insulating them still improves balance and prevents condensation.

Why Vapor Barriers Improve Insulation Performance

Insulation facings serve as vapor barriers, especially important in humid or unconditioned environments. They prevent water vapor from reaching the duct’s cold surface. This barrier reduces the risk of condensation and mold.

Facings also improve fire resistance and mechanical durability.

- Every seam and edge must be sealed to preserve the integrity of the barrier.

- Tape should match the insulation type to ensure adhesion.

When insulating ductwork in high-humidity environments, vapor barriers are necessary to maintain insulation performance and indoor air quality.

Long-Term Results Depend on Proper Material Selection

Materials rated for both jobsite wear and energy codes perform more reliably over time. They also reduce the chance of callbacks and system imbalance. Products that hold their R-value in real conditions protect the investment made in HVAC systems.

Choosing proven products helps ensure success when insulating ductwork in environments with heat cycling, vibration, or high moisture exposure.

Insulation should retain its loft and structure. Over time, compressed or degraded wrap loses its ability to resist heat flow. Installers should follow all product guidance to avoid future failures. Ductwork should be inspected each season to ensure insulation stays intact and seams remain sealed.

Field-Ready Wraps Simplify Installation in Harsh Conditions

Self-adhering insulation wraps reduce install time and increase reliability. These products eliminate the need for separate fasteners and adhesives. They’re especially effective in rooftop, exterior, or high-humidity areas.

Peel-and-stick designs allow installers to reposition and reseal sections as needed. This flexibility reduces installation errors and helps maintain a consistent insulation layer across bends and transitions.

This approach is especially useful when insulating ductwork in tight spaces or retrofit conditions.

High-Performance Polyguard Products for Duct Insulation and Vapor Control

Polyguard offers a range of mechanical insulation wraps designed for HVAC ductwork in both exposed and protected conditions. These materials improve thermal retention, resist weather damage, and simplify sealing on new and retrofit projects.

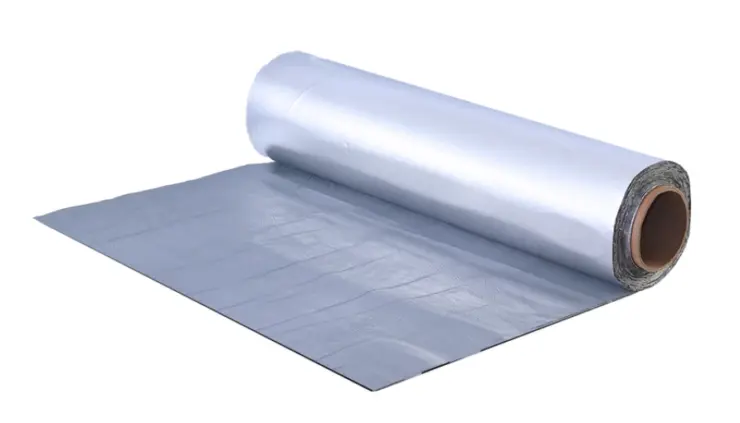

Alumaguard®: Flexible Vapor Barrier for Exterior Ducts

Alumaguard® is a multi-ply membrane engineered to act as both a vapor barrier and weatherproofing jacket. It installs over insulation to protect against UV, rain, and mechanical wear. The self-adhesive backing adheres directly to foil-faced or fiberglass insulation, creating a durable outer layer for rooftop or exposed systems. Alumaguard is especially useful in high-humidity environments where moisture intrusion threatens insulation integrity.

Alumaguard® All-Weather: Cold-Weather Performance Without Heat Guns

Alumaguard® All-Weather offers the same protection as the original but installs at low temperatures without surface priming or heating tools. It maintains flexibility in cold climates and bonds reliably even during winter installs. This makes it a practical choice for duct insulation on commercial roofs or outdoor systems in northern regions. The pressure-sensitive adhesive reduces install time and creates a sealed, reinforced barrier against moisture, UV, and thermal loss.

RG-2400® Series: Exterior Jacketing for Long-Term Durability

The RG-2400® Series includes high-strength jacketing systems built for industrial and commercial duct systems. These jackets protect against UV degradation, impact, and environmental wear while maintaining thermal performance. They are especially effective on horizontal rooftop ducts, vertical chases, or mechanical room ducts requiring long-term resilience.

Improve HVAC Duct Performance with Polyguard Insulation Products

At Polyguard, we manufacture high-performance wraps, barriers, and jacketing systems that simplify installation and deliver lasting protection. Our products resist moisture, support energy code compliance, and install cleanly on both residential and commercial ductwork. Contact us today for more information.