Properly installed and maintained pavement waterproofing membranes minimize repair and maintenance costs and extend the pavement’s service life. The long-term effectiveness of waterproof pavement depends on preventing deterioration due to moisture and chemical contamination and managing the salt-laden water that attacks the pavement.

Why Waterproof Pavement?

Pavement waterproofing will slow the pavement's rate of deterioration and help ensure its safe, long-term use. Protecting pavements with high-quality waterproofing will also limit closures, lessen long-term capital expenditure costs, and help maintain the pavement’s value. Conversely, inadequate waterproofing often results in costly structural repairs, loss of revenue, extensive closures, and vehicle damage.

Studies Reflect the Value of Pavement Waterproofing

A four-year evaluation of seven chloride-contaminated bridge decks found that adequate selection and application of waterproofing membranes reduces the oxygen and moisture supply at the rebar level enough to lessen corrosion to a non-destructive level. Furthermore, a six-year Georgia DOT study on 20 test sections of I-85 found that waterproofing membranes will reduce the rate of reflective cracking. In addition, with membrane treatment, reflective cracking over joints will stay tighter than those without membrane treatment.

A properly installed, well-maintained, high-quality waterproofing system, like Polyguard's 665 Membrane, NW75 Membrane, Cold Flex™ Membrane, and 650 Sheet Membrane, provides pavement with a front-line defense against damaging moisture, salt-infused water, and chemicals.

What to Consider When Waterproofing Pavement

Preventing water pavement damage demands professional design instructions, like from Polyguard waterproofing specialists. Our team can help you avoid crucial waterproofing pavement design mistakes during construction, particularly regarding terminations, transitions, and penetrations, which can cause time delays, budget overages, and costly litigation.

A Strong Waterproofing Design

The waterproofing pavement system must withstand an aggressive environment, with heavy wear and tear from trucks, cars, and other vehicles. A poorly designed pavement waterproofing system will quickly deteriorate and allow moisture and chloride to infiltrate the system.

An effective waterproofing system bridges cracks that open and close with temperature changes and cyclical loading as the pavement ages. Not bridging cracks will create a path for moisture and chlorides to infiltrate a surface-applied waterproofing system, that leads to corrosion of the rebar.

Sealing Joints in Pavement

You must correctly engineer and install joint sealants to maximize the pavement's lifespan and avoid significant maintenance and repair costs. Properly applied joint sealant will limit surface water infiltration and incompressible material into the joint system. Sealants also lessen dowel bar corrosion potential by decreasing the entrance of de-icing chemicals.

Designing sealing joints should consider sealant material, expected joint movement, and joint configuration. You can reference ASTM C1193 and ASTM C1299 for more information on joint design.

Selecting a Quality Sealant for Joints

Joint sealants must adhere to clean concrete, accept joint movement, and resist extreme environmental conditions. The market provides single and multiple-component products.

The physical demands of pavement joint sealants require a primer to protect against unplanned conditions, like long-term snow cover, ponding water, chemical exposure, and some forms of surface contamination. The pavement's joint design should also accept sealants capable of ±25 percent movement. However, some sealants can take 100 percent extension and 50 percent compression. Designing to the lower movement standard may lead to errors.

To combat mechanical forces on the sealants from trucks, cars, etc., you must recess the sealant from the surface of the concrete. The sealant must resist heavy heat and UV (ultraviolet) rays, particularly in warm climates like Florida and Texas. In Maine and Michigan, the sealant must withstand extreme cold and snow and the abrasion of salt and sand on the surface.

Providing Proper Drainage to the Pavement

Draining water away from the pavement will protect the waterproofing membrane and concrete slab, all essential to the pavement’s service life. Extensive damage will happen if pooled water freezes and thaws in colder climates. Therefore, waterproofing pavement must include a drainage system that directs water away from the pavement.

Polyguard Pavement Waterproofing Membranes

Polyguard pavement membranes protect pavement bases, bridge decks, and highways from water and moisture infiltration damages. Here are a few of the products that Polyguard provides for Pavement waterproofing:

Durable Polyguard 665 Waterproofing Membrane

Self-sealing, 665 Waterproofing Membrane comprises rubberized asphalt laminated to a woven solid polypropylene mesh backing. It forms a minimum 65-mile membrane that works effectively on asphalt and concrete pavements, and bridges for crack control and waterproofing.

Flexible and long-lasting 665 waterproofing membranes, with a perm of 0.05, protect and offer a superior bond to pavement surfaces with long-term waterproofing. It maintains its integrity against environmental attacks and traffic to extend the pavement service life. Polyguard sells 665 waterproofing membranes in 12 to 48-inch widths, which can be cold-applied without special adhesives and cause minimal traffic disruption.

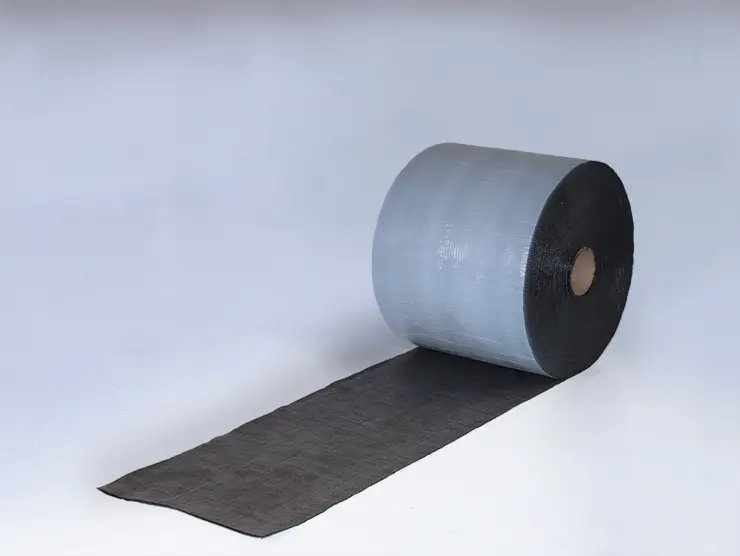

NW75 Pavement Membrane

Peel and stick Polyguard NW75 reinforces breakup and reduces corrosion and cracking. In addition, the waterproofing seal built into the NW75 prevents water infiltration. Polyguard NW75 contains non-woven polypropylene fabric laminated to a rubberized asphalt waterproofing sealant adhesive. The non-woven geotextile fabric's open fibers provide a mechanical bond to the new asphalt overlay, while the rubberized asphalt sealant-adhesive bonds to the existing pavement surface.

NW75 Waterproofing Membrane, with a perm of 0.05, protects the long-term pavement waterproofing by maintaining its integrity against traffic and environmental attacks, limiting structural deterioration, and extending the pavement service life of the overlay and bridge deck. It comes in 12 to 48-inch widths and is compatible with both concrete and asphalt pavements, helping it become one of the most popular pavement waterproofing application.

Polyguard Cold Flex™ Membrane

High-strength, 135-mil, peel-and-stick Cold Flex™ Membrane waterproofing membrane lowers the severity and occurrence of reflective cracking in new pavement overlay and potential water infiltration. Cold Flex™ Membrane can be applied to cracks or joints on the existing pavement before applying a new asphalt overlay. The membrane acts as an "umbrella" over cracks and joints in order to limit moisture penetration of the existing pavement and subbase.

Cold Flex™ Membrane has a top layer of high-strength fabric with a thick layer of rubberized asphalt adhesive sealant (reinforced with a second layer of high-strength fabric) for stress relief and waterproofing. Available in widths from 12” – 48”, it can be hot-applied or self-applied while still maintaining an exceptional bond to pavement surfaces.

650 RC Liquid Adhesive

We suggest applying 650 RC Liquid Adhesive before installing a waterproofing membrane to concrete bridge decks or milled pavement surfaces. Between temperatures of 40ºF (4.44°C) and 50ºF (10°C), new asphalt pavement surfaces do not require adhesive. You only need liquid adhesive for asphalt surfaces (except milled surfaces) at temperatures less than 70ºF (21.11°C) or old concrete.

Polyguard 650 RC Liquid Adhesive is a solvent-based, asphaltic liquid adhesive primer applied below waterproofing membranes. It improves the bond between the membrane and the pavement. Simple to apply, 650 RC Liquid Adhesive meets the requirements of ASTM D-41.

Polyflow® 18 Drainage Mat

The design of Polyguard's high-capacity Polyflow® 18 Drainage Mat offers a lightweight drainage solution that is compatible with our engineered sheet and liquid membrane products.

Lightweight and easy to install, the Polyflow® 18 drainage mat has a compressive strength of 21,000 psf and can handle the most challenging horizontal applications like split slabs, parking decks, and plazas. This product uses a woven filter fabric designed for concrete pours to facilitate flow under loaded conditions.

Protecting Pavement with Polyguard Waterproofing Pavement Products

To protect pavement from moisture and chemical damages, it’s important to install a proper waterproofing system. Not only can doing so save you money on repair and maintenance requests, but it can also keep the pavement safer for the traffic that is on it.

Contact our professionals at Polyguard for more information on waterproofing pavement.