Moisture intrusion is one of the most costly and persistent threats to a building’s long-term performance. Construction professionals rely on precision when specifying products that protect the building envelope from hidden failures. That’s why understanding the function and application of a polyethylene vapor barrier is essential for achieving consistent, code-aligned results.

The Material Behind Moisture Control

Polyethylene is a durable and flexible thermoplastic that offers low vapor permeability, making it ideal for resisting water vapor diffusion.

- Its use in building applications has grown due to its performance under slab-on-grade construction and other moisture-sensitive environments.

- Builders count on it to separate the moisture-rich ground from structural elements like insulation, flooring, and embedded reinforcements.

Though often concealed within the structure, vapor barriers play a decisive role in protecting system integrity and are a frequent source of failure when improperly installed or omitted.

Selecting the Correct Barrier Thickness and Design

The range of thicknesses available for vapor barriers directly impacts their durability and placement. While lightweight sheets might hold up in protected areas, most job sites demand thicker materials in the 10 to 15 mil range to withstand traffic and installation over rough substrates. In these conditions, puncture resistance isn’t a bonus, it’s a baseline requirement.

Reinforced polyethylene vapor barriers provide even greater strength by incorporating mesh layers that prevent tearing while still allowing flexibility. This becomes especially useful on job sites where movement, sharp rebar, or subbase irregularities can cause thin materials to fail during installation or early concrete placement.

Where Standard Polyethylene Falls Short

While polyethylene vapor barriers offer broad utility, commodity-grade sheeting often lacks the consistency and resilience required for demanding applications. These basic films can vary in thickness and quality, making them vulnerable to tearing during installation or under slab loads. Their performance is especially inconsistent over rough or uneven substrates, where minor movement or puncture can compromise the barrier plane entirely.

Sealing challenges also arise around complex penetrations, footing transitions, and irregular surfaces. Without integrated reinforcement or system-based sealing materials, traditional sheeting leaves room for moisture intrusion that may not reveal itself until long after construction is complete. These limitations highlight the performance gap between generic polyethylene rolls and the multi-layered, purpose-engineered assemblies offered by Polyguard.

Advanced Vapor Barrier Solutions by Polyguard

To overcome these limitations, Polyguard designs advanced barrier systems that incorporate polyethylene films into multi-layered assemblies, delivering significantly stronger performance profiles across a variety of industrial and building construction applications.

1. Insulrap™ 30-SJ: Self-Healing Below-Grade Protection

Insulrap™ 30-SJ is a fiberglass-reinforced composite membrane designed specifically for mechanical insulation applications in industrial HVAC and temperature-controlled facilities. Featuring a polymer film coated with rubberized asphalt, it delivers superior puncture resistance and self-healing properties that support reliable below-grade protection in demanding industrial environments. Its durability and sealing consistency make it well suited for applications where performance and longevity are critical.

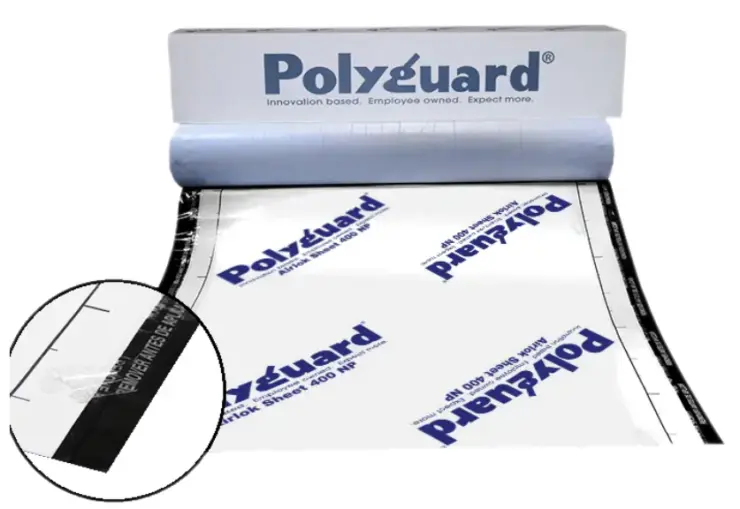

2. Airlok® Sheet 400 NP: Zero-Perm Air and Moisture Control

Airlok® Sheet 400 NP combines a cross-laminated polyethylene layer with a modified-asphalt adhesive to form a highly durable, zero-perm membrane. It’s engineered for air and moisture barrier performance in structural wall systems, offering long-term adhesion and weather resistance even in extreme conditions.

3. ZeroPerm® Membranes: Maximum Vapor Exclusion

ZeroPerm® vapor barriers feature a multi-layer composite that includes foil-faced polyester and polyethylene films. This system is designed for applications that require absolute moisture exclusion, ideal for controlled environments, sensitive materials storage, or high-humidity facilities. Its zero permeance rating ensures full vapor stoppage across the barrier plane.

Each of these assemblies uses polyethylene as part of a system, but they are engineered far beyond commodity-grade sheeting.

Installation Quality Directly Impacts Performance

No vapor barrier will perform as intended if it’s installed incorrectly. Seams must be overlapped and sealed with tapes or adhesives that meet ASTM standards. The system needs to remain uninterrupted, tightly fitted around footings, piers, or service penetrations, and secured so it won’t shift during concrete pours or slab preparation. Even minor defects, like torn corners or improper overlaps, can compromise long-term performance, especially once hidden beneath cured concrete.

Matching Barrier Performance to Application Type

Different construction types place unique demands on vapor barrier materials. In residential projects, polyethylene vapor barriers are commonly installed beneath basements and crawl spaces to block moisture migration. These settings are particularly vulnerable to seasonal moisture swings, condensation, and indoor humidity shifts that impact comfort and indoor air quality.

Climate and Structural Considerations

- Homes built in colder climates or flood-prone areas may require barriers with higher tensile strength or additional drainage planning.

- Commercial structures, such as warehouses or manufacturing spaces, call for vapor barriers that maintain their integrity beneath expansive slabs under heavy load conditions.

- Climate zone and site-specific variables, like groundwater levels or freeze-thaw cycles, must also be factored into the design and specification process.

Barrier Placement in Wall and Roof Assemblies

Barrier placement in walls and roofs must account for the building’s thermal boundary and seasonal vapor drive. In assemblies that include rigid insulation and air barriers, the vapor barrier functions as one component of a coordinated moisture control system. It must be positioned where it blocks inward vapor diffusion without preventing drying potential.

Design teams should address this detailing early in the specification phase, not in the field, ensuring that placement supports both performance and building longevity.

Code Compliance and Material Standards

Many regional building codes reference ASTM criteria for vapor barrier materials, particularly those used below grade or under structural slabs. Standards for puncture resistance, tensile strength, and vapor permeance ensure that materials used on site perform consistently across applications. Polyethylene vapor barriers that meet or exceed these requirements give builders confidence in passing inspections and satisfying warranty criteria.

Lower-grade polyethylene sheeting, such as agricultural or non-rated products, often lacks the uniformity and traceability required for permanent installations. Polyguard’s vapor barrier systems are designed to meet the most rigorous industry expectations, offering documented strength, zero-perm options, and verified assembly performance.

Long-Term Value Through Consistency

The consistency of material thickness, composition, and sealability separates a high-performance vapor barrier from basic plastic sheeting. With so many systems relying on effective moisture exclusion, insulation, adhesives, flooring, any breach in the barrier can trigger a cascade of failures. These issues may surface years after construction, often requiring invasive repairs and disrupting occupied spaces.

Proven Performance in the Field

Field-proven vapor barriers do more than prevent failure, they help protect operational budgets and occupant comfort. When moisture is properly managed at the barrier level, insulation retains its R-value, adhesives maintain their bond, and HVAC systems operate under consistent conditions. These outcomes translate to lower energy costs, fewer maintenance issues, and stronger long-term value for building owners and facility managers.

Build with Confidence Using Polyguard Polyethylene Vapor Barriers

Polyguard’s engineered systems offer a dependable upgrade from conventional plastic sheeting, incorporating polyethylene into high-performance composite membranes. Used beneath slabs or integrated into air and moisture control systems, these solutions deliver long-term resilience where it matters most. Contact us today for more information.