Preventing road deterioration and steel reinforcement corrosion to the bridge deck requires repair methods that stop moisture and chloride exposure as well as infiltration to the bridge deck. In addition, a properly implemented concrete bridge deck repair should:

- Protect the bridge's integrity and extend its life

- Preserve the infrastructure's safety

- Lessen maintenance and repairs that can lead to disruptive and costly bridge closure

- Contribute towards a sustainable design that avoids demolition and rebuilding

Many of the aging bridges in the U.S. desperately need repairs or replacement, which poses a financial and safety risk to numerous towns and cities. The American Road and Transportation Builders Association (ARTBA) reports that of the 617,000 U.S. bridges, one in three need replacement or repair, with three percent (6,191 bridges) explicitly requiring deck rehabilitation. It is a situation that offers bridge deck waterproofing professionals a significant business opportunity.

Causes of Bridge Deck Deterioration

Many factors threaten the integrity of bridges, particularly those not protected with a bridge deck membrane system and surface overlay:

- Increasing traffic levels

- Greater weight of today’s vehicles

- Exposure to harsh weather

- Chloride ions from de-icing salts

Why Bridge Deck Repairs Need Bridge Deck Waterproofing

Repairing a bridge deck with a bridge deck waterproofing membrane can protect against early deterioration, expensive repairs, potential replacement, and unsafe road conditions. The bridge deck waterproofing membrane under the overlay provides the following protections:

- Stops de-icing salt from passing through cracks of a concrete bridge deck that can cause reinforcement corrosion. Chloride and moisture will deteriorate concrete bridge decks and cause scaling, cracking, spalling, and corrosion of the steel bars within the concrete.

- Stops water from infiltrating through bridge cracks, which causes freeze-thaw damage to the bridge deck

- Limits oxygen and moisture from oxidizing and corroding the bridge’s steel parts, which leads to further cracks, spalls, and corrosion

- Protects a bridge if a tanker leaks dangerous chemicals, which will deteriorate concrete bridge decks

Polyguard Bridge Deck Waterproofing Membranes

Polyguard bridge deck waterproofing membrane is the best option for bridge deck repair to protect the bridge's long-term integrity, increase its lifespan, reduce maintenance and repairs, and ensure the infrastructure's safety.

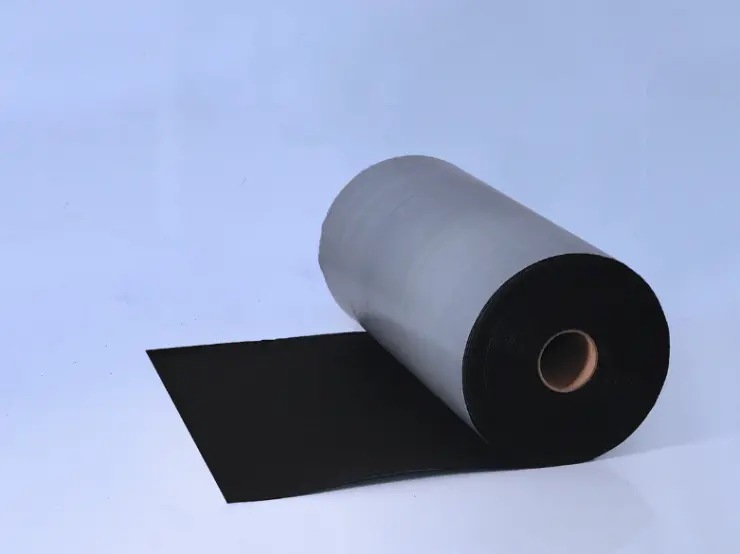

Most states' Department of Transportation recognizes Polyguard Pavement membranes for repairing and protecting bridge decks from moisture. Our membranes contain a rubberized asphalt waterproofing adhesive that is laminated to polypropylene fabric backings. A disposable silicone-treated release sheet is applied to the laminated membrane to stop the membrane from sticking to itself while in the roll.

Tough and Durable 665 Waterproofing Membrane

As a self-sealing product, the 665 Waterproofing Membrane helps bridge deck repairs by providing crack control and waterproofing. Furthermore, the rubberized asphalt, which is laminated to a woven solid polypropylene mesh backing, provides a minimum 65-mile membrane on bridges. This acts as a durable, long lasting bridge deck repair method.

NW75 Bridge Deck Membrane

To reinforce breakups and limit corrosion and cracking, Polyguard NW75 waterproofing seal is built to block water infiltration.

Not to mention, NW75 can protect a bridge’s integrity against traffic and environmental attack while also limiting structural deterioration and extending the life of the bridge deck overlay.

650 RC Liquid Adhesive

Polyguard recommends applying 650 RC Liquid Adhesive before the membrane to concrete bridge decks. New asphalt pavement surfaces do not require adhesive between 40ºF (4.44°C) and 50ºF (10°C). Only use liquid adhesive for asphalt surfaces (except milled surfaces) for temperatures less than 70ºF (21°).

Applying solvent-based Polyguard 650 RC Liquid Adhesive asphaltic primer under waterproofing membranes improves the bond between the pavement and membrane. Simple-to-apply, 650 RC Liquid Adhesive meets the requirements of ASTM D-41.

Polyguard Products for Bridge Deck Repair

Polyguard waterproofing membranes and companion products for bridge deck repair is the best solution for renovating damaged concrete bridges. Our waterproofing products will prevent chlorides and moisture from infiltrating a bridge deck to prevent deterioration and corrosion.

By applying Polyguards’ high-quality products to existing (and new) bridge decks, you can preserve their integrity, extend their life spans, decrease costly repairs, and help avoid expensive and disruptive bridge closures, and improve the infrastructure’s safety.

For more information on using bridge deck waterproofing membranes for bridge deck repair, don’t hesitate to contact the professionals at Polyguard today!