The integration of road membranes into construction and infrastructure projects marks a significant advancement in the longevity and durability of roadways. These critical components play a vital role in enhancing the performance and sustainability of road surfaces.

This guide aims to equip professionals with the essential knowledge to select and utilize the most suitable road membranes for their specific project requirements by highlighting the benefits and applications of geotextile membranes in road construction.

Introduction to Geotextile Membranes for Road Construction

Road membranes are specialized, permeable fabrics designed to reinforce, protect, and stabilize the ground under roadways. They are crucial for preventing soil erosion, improving drainage, and separating layers of aggregate and soil. Geotextile membranes, in particular, are a robust solution for reinforcing the soil beneath roads, which makes them indispensable in modern road construction practices.

Exploring the Types and Benefits of Road Membranes

There are various types of road membranes available, each with a specific function:

Geotextile Membranes

Ideal for separation and reinforcement, geotextile membranes are made from synthetic fibers and are highly permeable, which makes them perfect for drainage applications.

Asphalt Overlay Membranes

Asphalt Overlay Membranes are used to prevent water ingress and protect the pavement structure.

Grid and Mesh Membranes

Grid and mesh membranes are designed for soil stabilization and reinforcement, especially in areas prone to erosion.

Utilizing road membranes in construction projects offers numerous advantages:

- Durability and Longevity: Extends the life of roadways by preventing common issues such as rutting and cracking

- Cost-Effectiveness: Reduces the need for frequent repairs by enhancing the durability of roads

- Environmental Benefits: Supports sustainable construction practices by reducing the need for natural resources and minimizing runoff

Geotextile Membranes for Roads: Enhancing Road Durability and Efficiency

Geotextile membranes serve as a cornerstone for numerous road construction projects by providing solutions that markedly improve the durability, safety, and cost-effectiveness of road infrastructures.

Here’s a closer look at how these innovative materials are applied in the field:

Road Base Stability Enhancement

Geotextile membranes are instrumental in strengthening the road base as a robust foundation for road surfaces. By distributing loads more evenly and mitigating the risks of rutting and deformation, geotextile membranes help to ensure that roadways can withstand heavy traffic and adverse weather conditions over time.

Erosion Control Underneath Roads

One of the critical challenges in road construction is preventing soil erosion caused by water runoff. Geotextile membranes act as a barrier that protects the soil from erosion while also allowing water to drain effectively in order to preserve the road's structural integrity and longevity.

Improving Water Drainage Alongside Roadways

Proper drainage is vital for maintaining road quality and safety. Geotextile membranes, with their permeable nature, facilitate the swift and efficient removal of water from the roadbed. This prevents water accumulation, which can lead to surface damage and reduce the road's lifespan.

Practical Examples and Project Insights

The application of geotextile membranes in projects like the construction of highways in rain-prone areas or the reinforcement of roads on unstable soils showcases their versatility and effectiveness. For instance, the use of non-woven geotextiles for a highway project in a coastal region significantly reduced maintenance needs by preventing soil erosion and enhancing drainage, which extended the roadway's service life and helped to ensure smooth operation even under heavy rainfall.

Integrating geotextile membranes into road construction not only addresses immediate engineering challenges, it also contributes to the long-term sustainability and efficiency of transportation networks. By leveraging these materials, professionals can deliver safer, more durable roads, to pave the way for future innovations in infrastructure development.

Selecting the Right Geotextile Membrane for Your Road Project

Choosing the right road membrane involves considering several factors:

- Climate: The local climate can significantly affect the choice of membrane, as certain materials perform better in specific weather conditions.

- Soil Type: The underlying soil type dictates the need for either separation or stabilization, which can influence membrane selection.

- Traffic Conditions: Heavier traffic loads necessitate more durable membranes to withstand the stress.

Polyguard’s experts can assist professionals in making the right choice by matching project needs with the ideal membrane solution.

Polyguard’s Road Membrane Solutions

Polyguard's comprehensive range of road membrane products includes solutions for most needs:

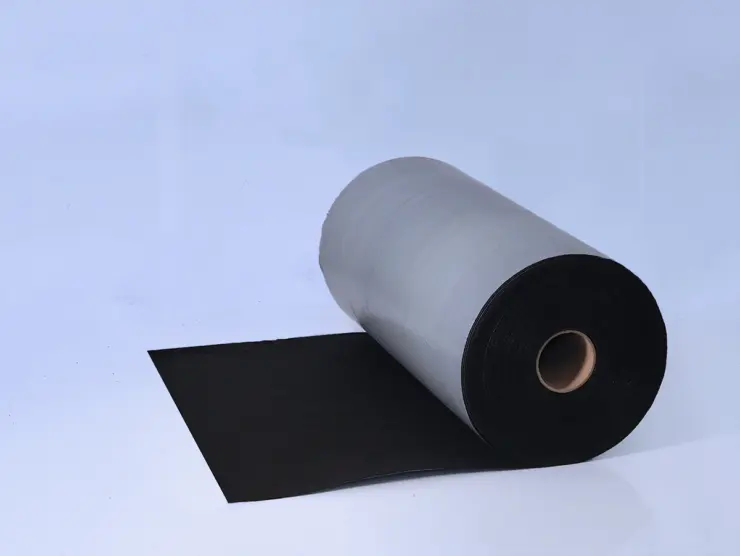

NW75 Membrane

The NW75 Membrane stands as a premier offering from Polyguard that is specifically engineered for applications that require superior separation and stabilization. The NW75 Membrane is best suited for waterproofing applications in highway and bridge deck constructions. It's designed to offer a reliable barrier against water ingress to protect the structural integrity of roads and bridges. It is particularly effective in environments where water protection is critical to maintaining the longevity and safety of infrastructure projects.

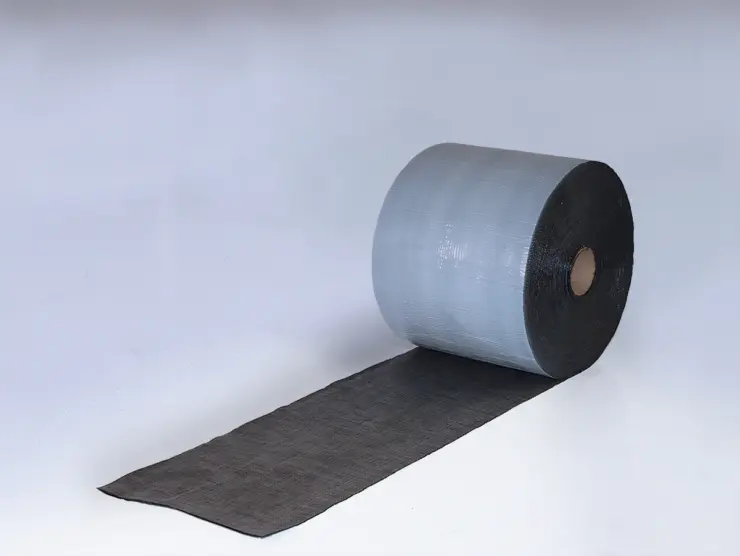

665 Membrane

The 665 Membrane is another cutting-edge solution from Polyguard that is tailored for projects that demand high-performance waterproofing and stress absorption. The 665 Membrane is designed for use in waterproofing applications across a variety of construction projects, including highways and bridge decks. Its primary function is to provide a robust barrier against moisture and water ingress in order to protect the structural components of these types of infrastructures.

650RC Liquid Adhesive

For projects that require a dependable bonding agent, the 650 RC Liquid Adhesive is a highly effective solution. This specialized adhesive is designed for use with Polyguard membranes to ensure a secure and durable bond under various environmental conditions. Its ease of application and compatibility with a wide range of materials make it an indispensable tool for any road construction project.

Membrane Installation Cart

The Membrane Installation Cart by Polyguard streamlines the process of deploying road membranes to make installation both quicker and more efficient. Designed with ease of use and operational efficiency in mind, it is an essential tool for professionals looking to enhance their road construction projects. Its adaptability to various membrane sizes and types ensures a versatile solution for a wide range of applications.

Versatile Applications of Membrane Technology Beyond Roadways

Beyond road construction, membranes have diverse applications in environmental engineering, agriculture, and building construction. They're used in waterproofing buildings, lining landfills to prevent leachate contamination, managing wastewater in treatment plants, and in agricultural practices to conserve soil moisture and improve crop yields.

Membranes also play a crucial role in constructing dams and embankments by offering stabilization and protection against erosion, which underscores their versatility across various sectors.

Discover Polyguard's Road Membrane Solutions

Explore the wide range of road membrane solutions at Polyguard to boost durability and efficiency in your road construction projects. Our products cater to diverse modern infrastructure needs in order to ensure top-notch quality and performance.

Contact us today for personalized advice on integrating our solutions into your next project!