Bridge deck construction is a crucial component of infrastructure development. It requires meticulous attention to detail, innovative approaches, and a deep comprehension of materials and construction techniques to guarantee the durability and safety of bridges for the long-term.

Understanding Bridge Decks

Bridge Decks

Bridge decks form the surface of the bridge, where vehicles and pedestrians travel. The design and construction of bridge decks can significantly affect the durability and functionality of bridge structures. Various types of bridge decks are used, each suitable for different span lengths and structural requirements:

Solid Slab Bridge Decks

Solid Slab Bridge Decks stand out for their straightforward construction and cost efficiency, which makes them an ideal choice for spans up to about 65 feet. This deck type benefits from simple formwork and reinforcement arrangements that lead to faster construction times and reduced costs for both the deck surface and associated approaches due to the reduced deck thickness.

Voided Slab Decks

Voided Slab Decks are optimized for medium spans, typically ranging between 65 to 98 feet, using polystyrene voids to decrease the structure's weight without sacrificing its strength. Although this design introduces additional complexity and costs, the reduction in concrete volume and self-weight is a significant advantage, particularly for medium-span applications.

T-Slab Sections

T-Slab Sections are engineered for their superior resistance to bending moments, which makes them suitable for spans between 65 and 131 feet. The sections can be precast or constructed on-site, with the design focused on minimizing deflection and compression. However, their complexity can introduce challenges, particularly in managing shear forces and potential cracking in areas where the cross-section changes.

Box Slab or Girder Sections

Box Slab or Girder Sections are favored for their economic and structural efficiency in applications that exceed 131 feet. Their design allows for a wider bridge with excellent torsion resistance, thanks to the presence of two webs and strong flanges. The box girder's interior space also provides utility accommodation, such as pipelines and cables to enhance the structure's functionality.

Steel Orthotropic and Composite Bridge Decks

Steel Orthotropic and Composite Bridge Decks represent advanced solutions that significantly reduce the structure's weight while also maintaining durability. These decks are particularly useful for specialized applications, given their installation ease and extended lifespan. However, it's essential to address potential fatigue issues in the design phase to ensure long-term durability.

Innovative Materials Transforming Bridge Deck Construction

Bridge deck construction is entering a new era, thanks to the adoption of advanced materials. Two such innovations, polymer concrete and fiber-reinforced polymers (FRPs), are at the forefront of this transformation.

Polymer Concrete

Known for its enhanced durability and lower maintenance needs, polymer concrete has emerged as a superior choice for fast-paced bridge construction projects. Its robustness makes it an attractive option, especially for accelerated bridge construction methods, that offers a longer lifespan with reduced upkeep.

Fibre-Reinforced Polymers (FRPs)

FRPs stand out for their exceptional strength-to-weight ratio, corrosion resistance, and adaptability. These materials are proving to be a valuable alternative to conventional construction materials, particularly in challenging environments or where reducing the structural weight is crucial. Their use in bridge decks not only ensures longevity, it also enhances the structure's resistance to environmental stresses.

These innovative materials are redefining the standards for bridge deck construction by extending their functional life and improving their aesthetic and structural qualities. Their introduction underscores the critical role of technological advancement in the evolution of bridge construction.

Step-by-Step Process of Concrete Bridge Deck Construction

1. Planning and Design: This phase is the blueprint of the project, where detailed planning, including environmental impact assessments and load analyses, takes place. It's crucial for selecting materials that are both environmentally sustainable and structurally sound.

b: Involves clearing the area and creating access paths, setting the stage for construction. This step is vital for ensuring a smooth operation throughout the project.

3. Foundation and Substructure Construction: The foundation supports the entire bridge, which makes its construction critical. This stage often involves driving piles into the ground and building substructures like piers and abutments that will support the bridge deck.

4. Formwork and Reinforcement: Here, formwork provides the mold for the concrete, while steel reinforcement adds tensile strength to the concrete structure. This combination is essential for the structural integrity of the bridge deck.

5. Pouring Concrete: The concrete mix is carefully prepared and poured into the formwork. This step requires careful monitoring of weather conditions to avoid issues that could compromise the concrete's strength.

6. Curing Concrete: After pouring, concrete needs to be properly cured to reach its maximum strength and durability. This stage is crucial for the longevity of the bridge deck.

7. Waterproofing and Protection: Applying waterproofing measures is critical for protecting the bridge deck from moisture and environmental damage, to ensure the structure's durability and longevity.

8. Final Touches and Quality Checks: The last step involves thorough inspections and any necessary finishing touches to ensure the bridge deck meets all safety and quality standards.

PolyGuard Waterproofing Solutions for Bridge Deck Construction

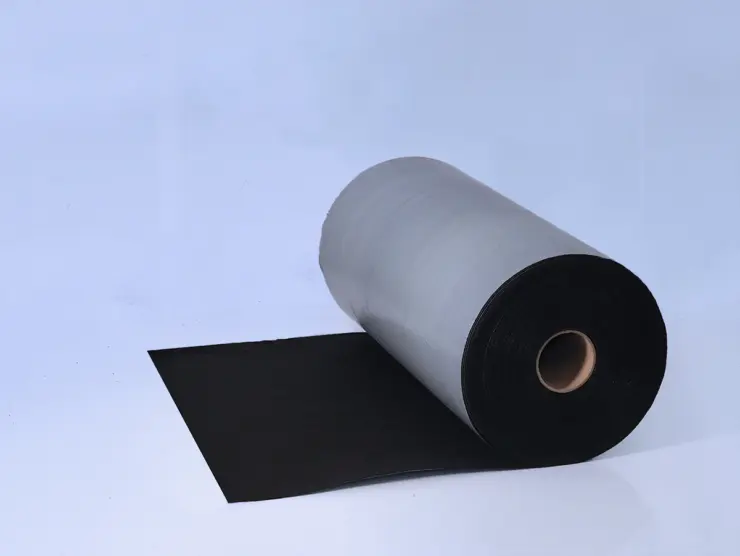

NW75 Membrane

This innovative waterproofing solution is designed specifically for bridge deck construction. This robust membrane provides unparalleled protection against moisture and environmental damages, ensuring the longevity and durability of the structure. Its easy application and superior performance make it an indispensable choice for engineers and construction professionals aiming for excellence in bridge projects.

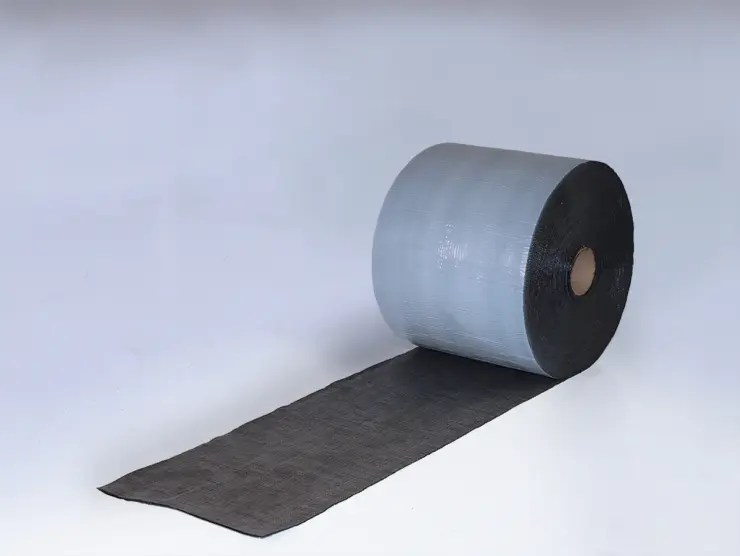

665 Membrane

The 665 Membrane is another cutting-edge solution from PolyGuard that has been designed to enhance bridge deck construction. Highly versatile and durable, this membrane is engineered for effective waterproofing and protection under various environmental conditions to ensure a robust defense against water ingress and structural damage. Its seamless integration with bridge construction practices makes it a favored choice among industry professionals.

650 Membrane

The 650 Sheet Membrane marks a revolutionary advancement in the field of bridge deck waterproofing. Its superior flexibility and high tensile strength allow it to accommodate natural bridge movements without compromising its waterproofing integrity. Ideal for a broad range of applications, this membrane ensures a dependable barrier against water and environmental elements to safeguard the bridge's structural health and longevity.

650 RC Liquid Adhesive

The 650 RC Liquid Adhesive serves as a critical component in the application of waterproofing membranes that ensures a strong and durable bond. Its formulation is designed for optimum compatibility with PolyGuard's waterproofing systems to provide an effective and reliable adhesive solution for bridge deck construction projects. This adhesive is known for its ease of application and rapid curing time, for a quicker project turnaround without compromising quality.

650 Mastic

650 Mastic is a highly resilient sealing compound that has been designed to complement the PolyGuard waterproofing systems. Its superior sealing capabilities ensure a watertight seal at critical junctions and points of vulnerability to enhance the overall integrity of the bridge deck construction. This product's ease of application and compatibility with a variety of materials make it an essential component for any waterproofing project.

LM 95

The LM 95 solution represents a leap forward in liquid waterproofing technology. Specially formulated for high-performance applications, it offers unparalleled resilience and adaptability across a variety of bridge deck environments. This product's innovative composition ensures lasting protection against moisture and environmental stressors, to solidify its position as a premier choice in modern bridge construction projects.

Each product is tailored for optimal performance in protecting bridge decks against moisture, chlorides, and deterioration, to help extend the lifespan of the infrastructure.

Preventive Measures for Common Construction Challenges

In bridge construction, many challenges can delay or disrupt projects. It's crucial to adopt thorough preventive measures to overcome these types of obstacles.

Weather-Related Delays

Implementing weather forecast monitoring systems allows project managers to plan construction activities around adverse weather conditions. Utilizing weather-resistant materials and construction methods can further reduce weather-related impacts.

Material Shortages

Establishing strong relationships with multiple suppliers and maintaining an inventory of critical materials can help circumvent the delays caused by material shortages. Early identification of material requirements and proactive procurement planning are vital.

Environmental Compliance Issues

Conducting thorough environmental impact assessments before construction begins ensures compliance with all regulatory requirements. Continuous monitoring and adherence to environmental protection plans minimize the risk of non-compliance penalties.

Labor Shortages and Skill Gaps

Investing in training programs to enhance the skills of the existing workforce and adopting automated construction technologies can alleviate the impacts of labor shortages. Building a pipeline of talent through apprenticeships and partnerships with educational institutions helps to ensure a skilled labor force for the future.

Safety Incidents

Implementing a comprehensive safety management system, including regular safety training, rigorous enforcement of safety protocols, and the use of personal protective equipment, can significantly reduce the risk of workplace accidents.

By proactively addressing these common construction challenges, project stakeholders can ensure smoother operations, minimize delays, and maintain the integrity of the construction timeline and budget.

Build Stronger with Polyguard: Transform Your Bridge Deck Projects

Polyguard's suite of waterproofing and sealing solutions stands at the forefront of innovation by offering unparalleled protection and durability for bridge deck projects. Our advanced technologies help to ensure that your projects are not only safeguarded against moisture and environmental damage, but are also completed on schedule, without compromising quality or safety.

Contact us today and speak with one of our experts for more information!