Not purchasable online

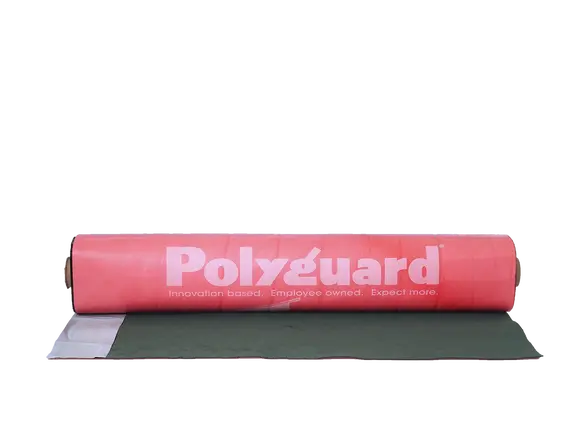

Underslab TRM

SKU: TERMUS50

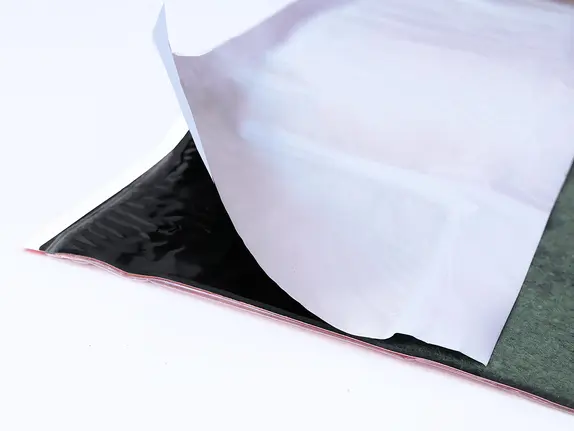

Underslab TRM is a pre-concrete pour waterproofing membrane/vapor barrier which also serves as a physical termite barrier.

Overview

Underslab TRM is a pre-concrete pour waterproofing membrane/vapor barrier which also serves as a physical termite barrier.

Key Features of Underslab TRM:

|

Companion Products

Here are some helpful items that work well with what you're buying. They make your project easier and better.

Product Resources

Underslab TRM – Detail Set (UST1-24)

- Termite Prevention

- Detail(s)

ICC-ES Evaluation Report 3632

- Termite Prevention

- ICC-ES Evaluation Report 3632

TRM Underlab - Methane Testing

- Termite Prevention

- Technical Sheet

Best Sellers

Explore our articles to learn more about products in application.