Although there are several different types of air barrier tests, every test has the same goal in mind: to verify the effectiveness of air barrier systems.

But what are the different types of air barrier testing methods, and how do you conduct an air barrier test yourself?

Here’s what you need to know.

What Are Air Barriers?

Air barriers are critical components in modern building envelopes that have been designed to prevent uncontrolled air leakage. The perform to main roles:

- Improve energy efficiency by minimizing the amount of conditioned air that escapes and by preventing unconditioned air from entering.

- Protect against moisture infiltration, which can lead to structural damage and mold growth.

Air barriers can be made from various materials, including fluid-applied membranes, sheet-applied products, and factory-bonded assemblies.

Why Air Barrier Testing Matters

Air barrier testing is essential for several reasons.

1. Ensure compliance with building codes and standards, such as those set by the United States Army Corps of Engineers and the International Energy Conservation Code (IECC).

2. Testing verifies that the air barrier performs as intended, to reduce energy costs by up to 30% through improved airtightness.

3. It helps identify and address potential failures, such as improper lapping or detailing, incompatible products, and lack of adhesion, which can compromise the barrier's effectiveness.

Different Types of Air Barrier Tests

Air Barrier Tests for Residential Buildings

Blower Door Test (ASTM E779)

- Purpose: To measure the air leakage rate of the entire building envelope.

- Procedure: Involves pressurizing and depressurizing the house using a blower door fan and measuring the air leakage rate. This test helps identify leaks and assesses the overall airtightness of the home.

Duct Leakage Test

- Purpose: To measure the air leakage in the duct system.

- Procedure: Uses a fan to pressurize the ductwork and measure the leakage rate, to help ensure that the ducts are properly sealed and not contributing to energy loss.

Thermal Imaging

- Purpose: To identify areas of heat loss and air infiltration.

- Procedure: Involves using infrared cameras to detect temperature differences on the surface of walls, ceilings, and floors, which can indicate air leaks.

Air Barrier Tests for Commercial Buildings

ASTM E2178: Standard Test Method for Air Permeance of Building Materials

- Purpose: To measure the air permeance of a single material.

- Procedure: Assesses whether a material is suitable as a component of an air barrier system. The air permeance limit is set at 0.004 cfm/ft² at 1.57 psf. This test is crucial for assessing the fundamental performance of air barrier materials before they are incorporated into a building system.

ASTM E2357: Standard Test Method for Determining Air Leakage of Air Barrier Assemblies

- Purpose: To evaluate the performance of an assembled air barrier system, including various penetrations such as pipes, brick ties, and electrical boxes.

- Procedure: Subjects the assembly to both positive and negative pressures by mimicking real-world conditions. An acceptable air leakage rate for this test must not exceed 10% of the leakage rate through an opaque wall assembly.

Whole Building Air Leakage Test (ASTM E779, ASTM E3158)

- Purpose: To measure the air leakage rate of large or multi-zone buildings.

- Procedure: Similar to the blower door test used in residential buildings but adapted for larger structures. These tests involve pressurizing and depressurizing the building and measuring the air leakage rate to ensure compliance with energy codes and standards.

Component Leakage Test (ASTM E1827)

- Purpose: To assess the air leakage of specific components such as windows, doors, and other penetrations.

- Procedure: Uses specialized equipment to test the airtightness of individual building components under various pressure conditions. This test helps identify and rectify leaks at critical points in the building envelope.

Infrared Thermography

- Purpose: To detect thermal anomalies that indicate air leakage and insulation defects.

- Procedure: Uses infrared cameras to capture thermal images of the building's envelope, identifying areas where heat is escaping and where air barriers may be failing. This test is often conducted in conjunction with other air leakage tests.

Smoke Testing

- Purpose: To visually identify air leaks in the building envelope.

- Procedure: Involves pressurizing the building and using smoke pencils or fog machines to visualize where air is escaping in order to provide a clear indication of leaks that need to be sealed.

Polyguard Above-Grade Air Barrier Solutions

Blue Barrier™ Gap Filler (BB GF)

BB GF is a fluid-applied air and moisture barrier designed for above-grade applications. It provides a seamless, durable barrier against air and moisture infiltration for enhanced energy efficiency and structural protection.

Blue Barrier™ Liquid Flashing (BB LF)

BB LF is a fluid-applied flashing membrane that seals around windows, doors, and other penetrations. It provides excellent adhesion to various substrates and ensures a watertight seal that enhances the overall air barrier system.

Blue Barrier™ Liquid Wrap (BB LW)

BB LW is a fluid-applied air and water barrier that creates a continuous, monolithic membrane that is easy to apply and provides superior protection against air and moisture infiltration for above-grade walls.

These products are integral to forming effective air barriers to enhance energy efficiency, and ensure the durability of above-grade residential structures.

Polyguard Below-Grade Air Barrier Solutions

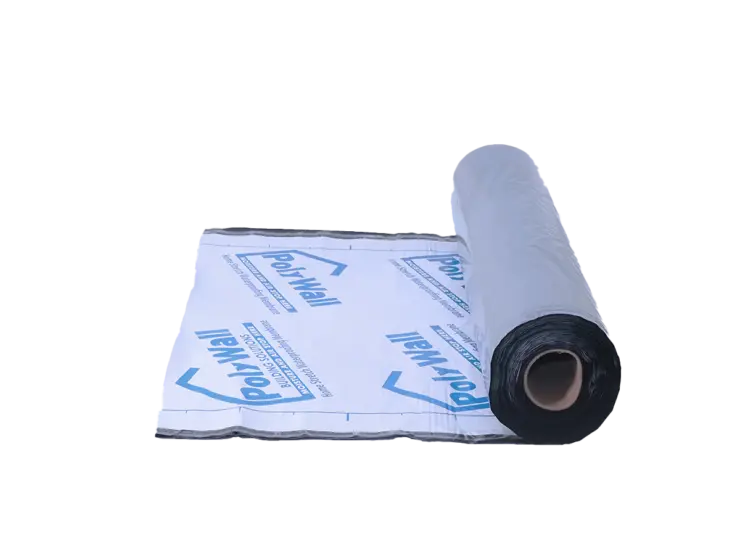

Home Stretch™ 40 Mil Membrane

This is a self-adhering, peel-and-stick waterproofing membrane designed for below-grade applications, such as foundations and basements. It provides a continuous barrier against moisture and hydrostatic pressure to ensure long-term structural protection.

Home Stretch™ Detail Tape

Home Stretch™ Detail Tape is a flexible, self-adhering tape that is used to seal penetrations, corners, and joints in conjunction with the Home Stretch Membrane. It enhances the overall integrity of the waterproofing system by ensuring a watertight seal at critical points.

Polyguard Stretch Flex

Polyguard Stretch Flex is a spray-applied waterproofing membrane designed for below-grade applications that offers flexibility and ease of application. It is suitable for use in various weather conditions, and provides a seamless barrier against moisture infiltration.

These products are essential for creating effective air and moisture barriers in below-grade residential structures for enhanced energy efficiency and structural integrity.

Ensure Optimal Air Barrier Performance with Polyguard

Partnering with Polyguard helps ensure that your building's air barrier system is effective and compliant with industry standards.

Our expertise in providing top-notch air barrier solutions guarantees enhanced energy efficiency and structural integrity for your projects–whether that’s residential or corporate buildings.

Want to try our air barrier solutions?

Contact us today for more information!