Strong, durable, and safe commercial buildings and homes need to have waterproof basement walls and floors. The goal in waterproofing a basement is to keep water and soil away from the below-grade walls and floor. For concrete basement walls, waterproofing requires installing a waterproofing membrane and a dimple drainage board.

Without effective waterproofing, porous basement concrete can crack from water pressure or the structure settling, which can allow groundwater, contaminated soil vapors, and insects to enter the home or building. The best way to waterproof a basement will create a moisture-free, below-grade building envelope, to protect the building or home's integrity, and reduce long-term maintenance and repair expenses, and to help prevent the following basement moisture-related problems:

- Structurally damaging and unhealthy mold

- Unpleasant smells in the basement

- Damage to the interior flooring

- Crystalline deposit of salts (efflorescence) on basement walls or floor

- Outward or Inward bowing walls

- Cracks in the walls

What is the Best Way to Waterproof a Basement? Polyguard's Solutions

Polyguard's basement waterproofing products provide residential and commercial solutions for the best way to waterproof:

- Basement Walls

- Basement Floor

- Basement from outside

- Basement from the inside

Residential Basement Waterproofing

Residential Solutions (a division of Polyguard) provides superior residential waterproofing basement products to protect against moisture and air infiltration, and add to a home's health, safety, and long-term integrity and value.

Commercial Basement Waterproofing

Polyguard's basement waterproofing products include membranes for pre-applied and post-applied applications, including fluid and sheet-applied products. The design of Polyguard products stands up to the most challenging conditions, and protects commercial concrete basement walls from water and contaminant infiltration due to imperfections in the concrete.

Polyguard also offers a solution to the best way to waterproof interior basement walls and floors with (Polyguard Underslab Membrane).

How Water Infiltrates a Basement

Water infiltrates a basement through door/window/vent openings, hydrostatic pressures, wall penetrations, poor site drainage, concrete cracking/mortar joints and movement, flooding, and high water tables. All these situations contribute to basement wall and floor leaks, and can cause complicated and expensive repairs. Before getting to that point, we usually recommend taking a moment to estimate what proper basement waterproofing might cost - it gives a clearer picture of the trade-off between prevention and later repair. In addition, high moisture levels will raise the relative humidity within a building or home, which increases the chance for condensation and unhealthy and damaging mold.

Fortunately, you can limit, if not stop, basement water intrusion by implementing waterproofing your basement into your structure's design.

Protecting your home or building from basement moisture infiltration also involves identifying and addressing possible water transport mechanisms through the walls and floor.

Does My New Basement Require Waterproofing?

The best way to waterproof a new basement construction involves implementing strategies to stop basement liquid and vapor water infiltration due to hydrostatic pressure and capillary action.

Hydrostatic pressure happens when gravity pushes static (stagnant-dense) water (hydro) against exterior basement walls built on a slope or partially or entirely below the water table. Hydrostatic pressure on basement walls causes moisture to enter through cracks and joints, and to permeate solid concrete through capillary action (wicking).

Code Requirements for Waterproofing a Basement

For reference, the 2021 International Building Code (IBC) (Section 1805) and the 2021 International Residential Code (IRC) (Section R406) specify the conditions that mandate either waterproofing or dampproofing a foundation.

Dampproofing aims to prevent moisture in the soil from infiltrating the basement wall. In contrast, waterproofing aims to keep water from the liquids and soil away from the below-grade walls. Waterproofing for concrete walls, however, also involves installing a waterproofing membrane and a dimple drainage board.

The best way to waterproof a basement must include the walls and floors.

Adequate waterproofing of basement walls will help them resist shear and bending stresses from lateral water and soil pressures. Basement walls must support the structures' weight, by transferring their load to the footing and into the ground, resisting wind and seismic forces, and providing anchorage.

What is the Best Way to Waterproof Basement Walls?

The best way to prevent water infiltration to basement walls by hydrostatic pressure and capillary action involves the installation of an impermeable membrane and drain board between the earth and the building or home.

Types of Basement Waterproofing Membranes

Manufacturers typically offer two membrane systems for waterproofing residential and commercial basement walls, prefabricated sheet membrane and fluid-applied membrane systems:

Prefabricated Sheet Membrane Systems

Prefabricated sheet membranes come as modified bitumen, bentonite, thermoplastic, or elastomeric membranes. Builders can simply apply prefabricated membranes or sheets to surfaces.

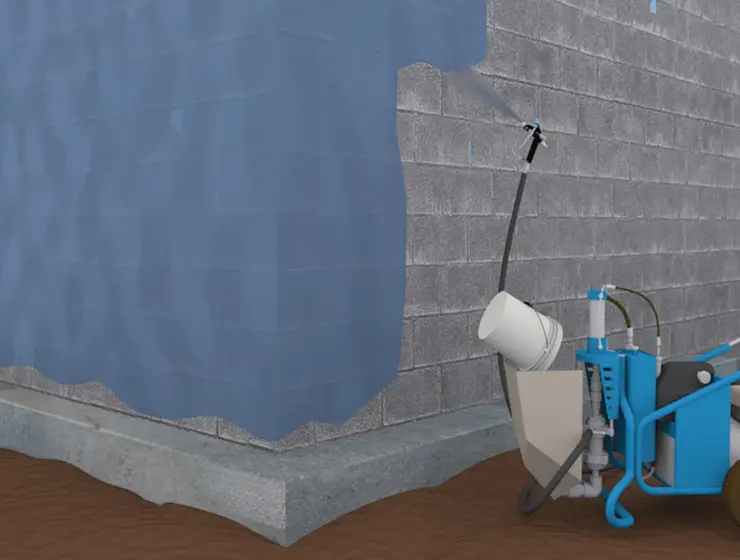

Fluid-Applied Membrane Systems

Fluid-applied membranes come as hot liquid-applied, cold liquid-applied, or single components. Builders can, hot or cold, apply liquid-applied waterproofing to properly prepared substrate surfaces.

What's the Best Way to Waterproof a Basement?

Application Techniques

There are three techniques for applying waterproofing membranes: negative-side, positive-side, and blind-side waterproofing.

- Negative-Side Waterproofing Membranes

Negative-side waterproofing membranes are the best way to waterproof the basement from the inside or the interior (dry) side of a building. Typically only done when you can't apply positive-side or blind-side waterproofing.

- Positive-Side (post-applied) Waterproofing

Positive-side waterproofing occurs after wall construction. It needs access to the outside face of the building.

- Blind-Side

Pre-applied on the outside face of the basement wall before building the foundation wall.

The Best Way to Waterproof a Basement Wall

The best way to waterproof a cinder block basement should protect the walls from soil and liquid moisture.

Substrate Preparation

To optimize waterproofing protection for residential and commercial basement walls, prepare the substrate as follows:

- Clean the basement wall and footing surfaces to ensure a debris-free and smooth surface.

- Before applying the concrete wall waterproofing membrane, check the manufacturer's literature for temperature limitations.

- Only apply membranes on fully cured concrete since vapor escaping from the concrete can prevent the waterproofing material from bonding.

- Waterproofing products do not cover large voids; therefore, you must apply a quality product like BBGF (Blue Barrier Gap Filler) to seal around joints and patch cracks and breaks in the walls.

BBGF (Blue Barrier Gap Filler)

Easy to apply, BBGF (Blue Barrier Gap Filler), developed using STPE technology, is a structural adhesive and detail sealant for filling substrate imperfections and to bond different materials. Environmentally-friendly BBGF helps ensure cleaner application beads while providing superior adhesions and excellent adhesion. It has a Class A surface burning rating, for added fire protection against smoke development and flame spread within a home or building.

Waterproofing Application

Apply waterproofing systems to all basement walls with earth on the exterior and usable space on the interior:

- Extend waterproofing at least 12 inches onto intersecting walls for added effectiveness.

- For wet sites, continue the waterproofing on other walls since the moisture may flow through the keyway, along the footing, and into occupied areas.

- Instruct workers not to walk across exposed membranes on footings, decks, or other horizontal surfaces, which can compromise the waterproofing system.

- Once applied, the waterproofing wall system needs a drainage mat or insulation to protect it during backfill.

Waterproofing Residential Basement Walls

Polyguard's Residential Solutions provides superior residential waterproofing basement products to protect against moisture and air infiltration, to significantly contribute to a home’s health, safety, and long-term integrity and value.

Residential Below-Grade Waterproofing Systems

Polyguard's Residential line offers two types of basement waterproofing systems: liquid and membrane.

Home Stretch™ Liquid Waterproofing

Builders can use Home Stretch™ Liquid Waterproofing on below-grade CMU, poured concrete, precast concrete, and other vertical foundation surfaces exposed to hydrostatic pressure. For complete foundation wall waterproofing, Polyguard Residential suggests using Home Stretch™ Liquid Waterproofing with BBGF (Blue Barrier Gap Filler), Drain Board, Totalflow T-Outlet, and Totalflow End Outlet Channel System.

WM40 for ICF Waterproofing

Polyguard engineered WM40 is specifically for insulated concrete form (ICF) walls; however, builders can also use them on CMU and poured concrete foundation walls. It offers the best way to waterproof exterior basement walls.

Straightforward and quick to install, WM40 ICF Waterproofing contains a self-adhering, 40 mils thick sheet waterproofing membrane made of a flexible, strong high-density polyethylene (HDPE) facing bonded to a rubberized asphalt waterproofing composite.

Builders can maximize Stretch Flex's effectiveness if combined with BBGF (Blue Barrier Gap Filler), Detail Tape, Liquid Waterproofing, Water Based Liquid Adhesive, Drain Board, and Quick Grip.

Waterproofing Commercial Basement Walls with Polyguard’s Waterproofing Systems

Polyguard’s basement waterproofing includes membranes for post-applied and pre-applied applications, including sheet and fluid-applied products. Polyguard products stand up to the most severe conditions, to protect concrete basement walls from water and contaminant infiltration due to cracks in the concrete.

Polyguard Basement Sheet Membranes

BLINDSIDE MEMBRANE

Builders can apply flexible, puncture-resistant 73 mils Blindside Membrane waterproofing membrane in spaces where soil retention does not permit access to the positive side. It applies vertically before concrete pouring. The curing concrete forms a mechanical bond with the membrane. Additionally, the cold flow characteristics of the membrane produce an outside adhesive layer that contributes to a tight seal and excellent protection against moisture infiltration.

Builders can also install the Blindside Membrane horizontally over a prepared sub-base like fine crushed beds/pea gravel, mud slab, carton forms, or Polyguard-approved drainboard.

650 MEMBRANE

Flexible, strong, 60-mil 650 Membrane, a self-adhesive waterproofing membrane/vapor retarder prevents vapor and water transmissions through poured concrete basement walls. ICF, wood, and CMU. The design of 650 Membranes allows them to be used in vertical/secure wall applications and horizontal/split slab applications for critical waterproofing projects,

Polyguard offers the 650 Membrane in a wide membrane (up to 48 inches), for fast and simple application to continuous flat surfaces. For trimming corners, construction joints, etc., Polyguard also offers the 650 Membrane in a narrow width.

650 PRM Puncture-Resistant Membrane

Strong, self-healing 65-mil 650 PRM is a post-concrete pour sheet waterproofing/vapor retarder membrane. It contains a double-thick, cross-laminated polyethylene backing laminated to a heavy layer of rubberized asphalt compound.

650 PRM sticks tightly and permanently to concrete. Its backing forms a continuous barrier to vapor and water entry.

Builders can use 650 PRM on the exterior vertical sides of concrete basement walls, along with related applications needing waterproofing, and for quicker waterproofing applications by eliminating the installation of an added protection course before backfilling operations.

Builders can also apply 650 PRM horizontally to plywood decks, parking garages, plaza decks, and similar applications. In most situations, it can be used as a concrete topping slab installation without requiring a separate protection course.

BELOW-GRADE FLUID-APPLIED WATERPROOFING

Stretch Flex Fluid-Applied Waterproofing

Polyguard’s Stretch Flex is a single component engineered with Polyguard's patented thermoplastic technology. It offers a cold-applied (as cold as -20° F) spray product that creates a durable, seamless, waterproofing membrane that bridges substrate shrinkage cracks up to 1/16-inch, to limit surface breaches and minimize problems at the joints. Polyguard has designed Stretch Flex for easy application to below-grade exterior waterproofing of concrete, CMU, precast concrete, basement walls, and other structural surfaces on the hydro-positive side.

The Best Way to Waterproof a Basement From the Inside

Polyguard has a solution to the best way to waterproof a basement from the inside walls.

The Best Way to Waterproof a Basement Floor

Water and vapor can infiltrate basement concrete slabs externally and internally, damage the flooring and building envelope, compromise the indoor air quality, and even raise energy bills:

Externally, moisture can come from poor drainage and plumbing, rain, below or at the slab's sides, poor ventilation, air humidity, etc. Internally, moisture comes from the amount of water in the cement used to create the concrete, which can tremendously impact the concrete slab's cure time. In addition, excess moisture in concrete enlarges the space between the cement's aggregates and lessens the compressive strength and durability of the concrete.

Managing concrete slab moisture on grade requires adequate installation, with proper curing and drying. Builders must also install a heavy-grade, low-permeance puncture-resistant floor moisture barrier, like the Polyguard Underslab Membrane. Our under-slab and above-slab products will shield the flooring from the structurally damaging, expensive, and unhealthy problems associated with vapor and moisture transmission through the concrete floor.

Under-Slab Moisture Barriers

Protecting concrete basement flooring from damaging moisture intrusion involves applying a non-penetrable, low-permanence, heavy-grade vapor barrier (or retarder) over a prepared sub-base layer like compacted mud slab, soil, #57 Stone, or carton forms.

The Concrete Floor and Slab Construction Guide suggests a minimum vapor retarder thickness of ten mils thick to withstand puncturing during and after construction. In addition, the ASTM E1745-17 and ASTM E1643 18a provide the guidelines for installing, using, and inspecting under concrete slab vapor barriers.

For vertical, horizontal, and shotcrete applications, tough 85-mill, pre-concrete pour, roll-on Underslab waterproofing membrane/vapor barrier effectively eliminates vapor and water transmission through concrete basement floors to protect floor finishes.

Underslab Membrane typically installs horizontally on top of sub-base like #57 stone, mud slab, or compacted soil. While pouring concrete, the concrete will blend with the fibers of the nonwoven geotextile, to provide a solid mechanical bond and a continuous seal under the concrete slab. Installation of Underslab Membrane should only happen at temperatures above 24°F (-4°C).

For vertical applications, builders should refer to the Blindside Membrane datasheet guidelines.

For shotcrete installations of the Underslab Membrane in the water table, builders should contact Polyguard Architectural Technical Services at archtech@polyguard.com.

The Best Way to Waterproof a Basement - Polyguard's Solutions

Polyguard's basement waterproofing products are residential and commercial solutions for waterproofing basement interior and exterior walls and floors.

For more on the best way to waterproof a basement, don't hesitate to contact our Polyguard professionals. We have answers to all your questions.