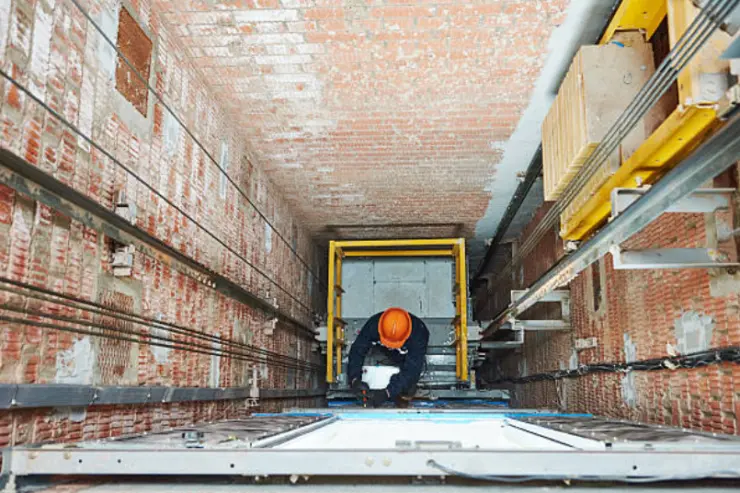

Elevator pits are among the most water-vulnerable areas in any structure. Set below grade and surrounded by concrete, they face constant groundwater and pressure exposure. Even small cracks or cold joints can allow infiltration that damages elevator equipment, corrodes reinforcement, and disrupts system operation.

Why Elevator Pits Require Dedicated Waterproofing

Elevator pits operate under continuous groundwater and structural pressure, making waterproofing a code-mandated performance requirement rather than a finishing detail.

Code and Structural Context

Polyguard engineers and specifiers view elevator pit waterproofing as a core responsibility for ensuring safety and long-term performance, not a finish detail. Below-grade spaces remain under constant hydraulic load from surrounding soils. When rain or groundwater levels rise, water seeks the path of least resistance through slab pores, joint gaps, or penetrations.

IBC §1805.3 requires waterproofing where structures are below the water table or subject to hydrostatic pressure. Elevator pits fall squarely into that category. Proper waterproofing keeps the pit dry under service conditions, preventing electrical shorts, rusted rails, and sump-pump failure.

Design and Performance Criteria

Designers must account for both vertical and lateral water forces. Slab-to-wall transitions, control joints, and pipe sleeves become common leakage points if not sealed with continuous membranes. Assemblies targeting ≤ 0.02 perms (E96 Method B) achieve Class I / very-low permeance—typical for below-grade vapor control in these assemblies.

Common Causes of Elevator Pit Water Intrusion

Moisture problems in elevator pits usually trace back to predictable field conditions. Inadequate drainage, underslab cracking, and poor joint treatment allow water to collect and rise. Cold joints—where separate concrete pours meet—form capillary channels that transmit water even when surfaces appear solid. Hydrostatic pressure then pushes that moisture through microscopic voids, saturating concrete from beneath.

A poorly designed sump worsens the problem by allowing backflow under load. Seasonal fluctuations exacerbate the issue: rising water tables in spring or heavy rainfall can overwhelm undersized drainage fields, introducing water faster than pumps can remove it. It’s predictable but preventable. Consistent elevator pit waterproofing requires a full-system approach that addresses both ingress and removal.

Elevator Pit Waterproofing Methods and Materials

A successful waterproofing design combines barrier continuity, substrate preparation, and drainage management. Each method below targets a specific side of potential infiltration.

Positive-Side Waterproofing Systems

Positive-side waterproofing defends against water before it enters the structure.

- Liquid-applied membranes meeting ASTM C836 bond directly to the exterior pit wall and slab. These systems bond into an elastic, seamless layer that moves with the ground without cracking. Reinforcing fabrics or mesh can be embedded at corners and penetrations for added tensile strength.

- For new construction, membranes are applied over primed concrete before backfilling.

- In retrofit work where exterior access is limited, positive-side coatings may still be applied from inside the pit using specialized negative-pressure formulations.

Long-term performance, however, depends on substrate dryness and verified adhesion data from the manufacturer.

Negative-Side Coatings and Crystalline Barriers

When exterior access is impossible, negative-side waterproofing allows crews to apply materials to the interior face of the concrete.

- Crystalline compounds react with free lime and moisture to form insoluble crystals within pores, reducing permeability throughout the matrix. While these systems can resist minor seepage, they are not substitutes for external membranes under continuous hydrostatic load.

- Elastomeric coatings formulated for negative-side application must meet ASTM C836 elongation standards to bridge existing cracks and resist water intrusion. Applying multiple coats ensures adequate dry-film thickness and uniform coverage across the slab and wall interface.

Even so, incorporating perimeter drainage relieves pressure and extends coating life. That’s the trade-off.

Drainage Mats, Sumps, and Redundancy Layers

Effective water management beneath the pit relies on directing, relieving, and containing hydrostatic pressure through multiple safeguards.

Drainage Mats and Flow Channels

No waterproofing assembly performs indefinitely under unchecked hydrostatic pressure. In the field, drainage mats installed outside or beneath the pit divert groundwater toward collection points—because under pressure, water always finds the easiest path to travel. These mats typically include filter fabrics to prevent soil clogging and maintain flow channels.

Sump Systems and Pressure Relief

Sump pumps remain the last line of defense. A sealed sump liner with backflow protection ensures that water removal does not reintroduce vapor. Periodic maintenance—clearing debris and verifying float switch function—keeps the system reliable. Pressure relief is the difference between control and failure.

Redundancy Layers for High-Risk Conditions

Redundancy layers such as bentonite panels or secondary membranes add resilience, particularly in high-risk soil conditions where pressure levels fluctuate or drainage access is limited.

Elevator Pit Waterproofing Details and Design Considerations

Proper detailing determines whether a waterproofing assembly performs over decades or fails in its first season.

Critical Joints and Reinforcement

Long-term performance depends on detailing precision. The slab-to-wall intersection is the most common failure zone in elevator pit waterproofing assemblies. A flexible joint sealant meeting ASTM C920 is required before applying membranes. Polyguard engineers recommend continuous reinforcement fabric at inside corners to distribute stress and prevent separation under hydrostatic pressure.

Penetrations and Termination Methods

Pipe penetrations, anchor bolts, and electrical conduits must be treated as individual leak paths. Each should be sealed with compatible elastomeric mastics or preformed boots that maintain adhesion as components shift. Termination bars at membrane edges prevent peel-back and create a mechanical bond between coatings and substrates. In design drawings, these are often marked under elevator pit waterproofing detail or elevator pit waterproofing details, indicating the locations most susceptible to capillary ingress.

Substrate Condition and Application Readiness

Confirm substrate dryness per product data (MVER/RH or moisture meter) and manufacturer instructions before coating. Coatings applied to damp or uncured concrete may blister or lose adhesion.

Polyguard Solutions for Elevator Pit Waterproofing

Polyguard manufactures membranes, coatings, and barrier systems designed for long-term below-grade service.

- 650 PRM, a self-adhered waterproofing/vapor retarder membrane, provides a perm rating of 0.01 (E96 Method B) and hydrostatic head resistance up to 231 feet.

- Stretch Flex elastomeric coating bridges cracks and interfaces while retaining flexibility across temperature cycles. When combined with Polyguard detail membranes at wall-floor transitions, the system forms a unified seal around the pit while maintaining adhesion through curing, shrinkage, and minor structural movement.

Polyguard’s membranes, including the Underslab Membrane and ZEROPERM® Vapor Barrier, have been field-tested in elevator pit applications where hydrostatic pressures are present. These materials are also suitable for mechanical spaces and sump areas when specified for these environments. Contractors can integrate them with existing below-grade systems to support designs that meet the intent of IBC §1805.3 for waterproofed structures.

Maintaining and Inspecting Elevator Pit Waterproofing

Even durable systems require inspection.

- Facilities should monitor for efflorescence, moisture staining, or pump cycling that indicates seepage behind the membrane.

- Annual checks confirm that termination bars remain tight and that sealants show no signs of separation.

- Re-coating intervals vary by exposure and product; follow manufacturer maintenance guidance for elastomeric coatings.

Where sump systems are active, electrical and alarm components should be checked concurrently. Ignore that cycle and problems return fast. Regular maintenance preserves membrane integrity and prevents costly elevator downtime.

Design and Compliance Questions for Elevator Pit Waterproofing

Design submittals often raise questions about code alignment, testing methods, and material performance in below-grade assemblies.

Additional Design and Compliance Context

Elevator safety provisions under ASME A17.1 require pit drainage or sump arrangements (and related restrictions) to be addressed so water is managed without compromising inspection or operation; effective waterproofing and drainage work together to meet that expectation.

Common Specification Questions

Q: Can negative-side coatings replace exterior membranes under hydrostatic load?

A: No. They reduce seepage but do not match positive-side performance when constant water pressure exists.

Q: What is a practical permeance target for elevator pit assemblies?

A: Class I vapor control—typically ≤ 0.02 perms (ASTM E96 Method B)—paired with exterior drainage to relieve pressure and extend coating life.

Specify Polyguard Systems for Long-Term Elevator Pit Protection

Polyguard’s below-grade membranes, coatings, and vapor barriers are engineered for environments exposed to hydrostatic pressure and moisture migration. Each system is designed to maintain adhesion, flexibility, and vapor impermeability over decades of service. Contact us today for more information.