Water, salts, and chemicals infiltrate highway pavement through cracks, shoulders and draining channels, and high groundwater that deteriorates the road causes cracking, scaling, spalling, potholes, corroding the steel bars commonly found in highway bridges.

Without the use of a highway waterproofing system, the deterioration of the road surface begins immediately after laying pavement.

In the U.S., nearly 162,118 miles of major highways, or 15.7 percent, are in poor or mediocre condition and need costly repaving or even more substantive repairs.

Why Apply a Highway Waterproofing System?

Installing a well-maintained, high-quality road waterproofing system under the asphalt overlay of a new or existing highway pavement reinforced pavement cracks and joints.

As a result, the installed waterproofing systems reduce reflective cracking within the asphalt concrete overlays by providing a front-line defense against damaging moisture, chemicals, and salt-infused water.

Properly applied, a highway waterproofing system can protect the road's integrity, extend its life, maintain a safe infrastructure, and lessen repairs and maintenance that can lead to costly and disruptive road closures.

Preventing water pavement damage requires professional design instruction, and the Polyguard road waterproofing experts and products, including 665 Membrane, NW75 Membrane, Cold Flex™ Membrane, and 650 Sheet Membrane, can help!

Road Surface Treatments and Highway Waterproofing

Highway waterproofing systems, like road surface treatments and highway waterproofing membranes, aim to protect the road's integrity, lifespan, and safety and reduce repairs and maintenance that can lead to expensive and disruptive closures.

Road Surface Treatments

Road surface treatments can help preserve and extend the life of a highway pavement project by protecting the underlying pavement, restoring surface characteristics, and improving skin resistance. While surface treatments do not offer structural strength, they limit or prevent water infiltration to support the inherent strength and subgrade of the pavement.

The market offers several fast, effective, and affordable treatments: asphalt rejuvenator, chip seal, and micro surfacing.

Asphalt Rejuvenator

Asphalt rejuvenation treatments seal the surface from moisture and extend the period during critical asphalt hardening. The treatment preserves existing striping, keeps the roads in good condition, and may extend the road life from four to five years.

An asphalt rejuvenator is applied at the top of the curve to seal the surface and preserve its durability. Asphalt rejuvenation replaces the petroleum maltenes in asphalt, which dissipate during manufacturing due to heat, weathering, and oxidation. Maltenes occur naturally in asphalt and create fluidity and cohesion, which gives asphalt its adhesion properties.

Chip-Seal

Chip-sealing waterproofs the underlying pavement, seals cracks, and creates a new wearing surface.

Spray applying an asphalt emulsion chip sealing, followed by surfacing of crushed aggregate, will waterproof a pavement just before an asphalt overlay. You can use a single-seal or double-coat seal for more deteriorated roads.

Micro-Surfacing

Micro-surfacing treatments create a new wearing surface to correct wheel rutting, to moderate pavement bleeding, flushing, raveling, minor cracking, and enhance skid resistance.

Micro-surfacing consists of a mixture of polymer-modified asphalt emulsion, water, 100 percent crushed aggregate, mineral filler, and setting additives. A micro-surfacing seal deposits a uniform wearing surface proportional to surface demand.

Highway Waterproofing Membranes

Applying a waterproofing membrane to new and existing highways will protect them against early deterioration, expensive repairs, and severe safety consequences.

In total, highway waterproofing membranes can:

- Prevent water from penetrating through cracks, which leads to freeze-thaw damage to the pavement surface. Moisture and oxygen will oxidize and corrode steel parts, often present in highway bridges, which cause further cracks and spalls that worsen corrosion.

- Prevent defrosting salt from passing through cracks in the concrete that will cause reinforcement corrosion. Moisture and chloride will deteriorate concrete pavement, and cause cracking, scaling, and spalling that will eventually erode the steel bars within the concrete.

- Protect a highway in the event of dangerous leakage of chemicals from tanker traffic, which can deteriorate concrete surfaces.

Polyguard Highway Waterproofing Paving Membranes and Companion Products

Polyguard highway waterproofing membranes protect road pavement and bridge decks from moisture and cracking by providing the best option to preserve the pavement's long-term integrity and safety—and to lessen maintenance and repairs.

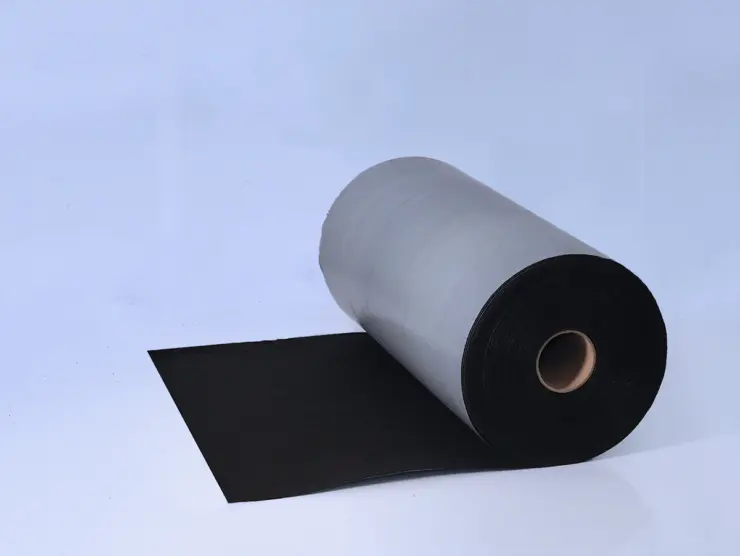

Polyguard pavement membranes are made of a rubberized asphalt waterproofing adhesive laminated to a woven polypropylene fabric backing. The laminated membrane has a disposable silicone-treated release sheet so it won't stick to itself in the roll.

Long-Lasting 665 Waterproofing Membrane

Polyguard’s 665 Waterproofing Membrane is a self-sealing rubberized asphalt laminated to a woven solid polypropylene mesh backing. Not only does it form a minimum 65-mil membrane that works effectively on highway asphalt, concrete pavements, and bridges for waterproofing and crack control, but it also enables for a quick application to reduce traffic concerns.

NW75 Pavement Membrane

Polyguard NW75 reinforces breakup and limits cracking and corrosion by creating a waterproof seal that stops water infiltration. Consisting of a non-woven polypropylene fabric laminated to a rubberized asphalt waterproofing sealant adhesive, Polyguard NW75’s non-woven geotextile fabric fibers to create a mechanical bond with new asphalt. The best part? The rubberized asphalt sealant-adhesive bonds to the existing pavement surface as well, making a universal application.

Polyguard Cold Flex™ Membrane

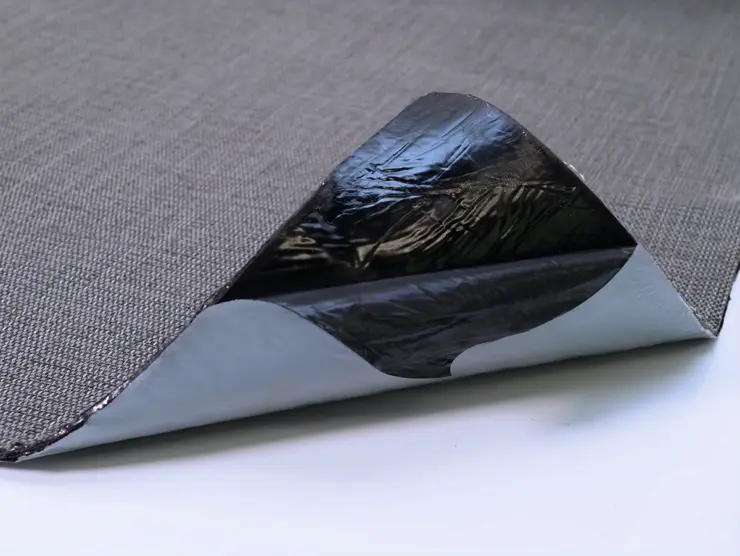

The 135-mil, peel-and-stick Cold Flex™ Membrane waterproofing membrane reduces the severity and occurrence of reflective cracking in new pavement overlay and potential water infiltration.

While being applicable to cracks or joints on the existing pavement before a new asphalt overlay, the Cold Flex™ Membrane acts as an "umbrella" over cracks and joints to limit moisture penetration of the existing pavement and subbase.

Polyguard 650 Sheet Membrane

One of Polyguards most durable and flexible materials after pouring concrete, 650 Sheet Membrane virtually eliminates water and vapor transmission through a concrete pavement.

Made of a 4-mil cross-laminated, high-density polyethylene (HDPE) backing bonded to 56 mils of rubberized asphalt waterproofing compound, 650 Sheet Membrane is an exceptional option for highway waterproofing applications.

Polyflow® 18 Drainage Mat

The Polyflow® 18 Drainage Mat has a compressive strength of 21,000 psf and can handle even the most challenging horizontal applications, including split slabs, parking decks, and plazas. Because it is lightweight and easy to install, this product is perfect to facilitate flow under loaded conditions, especially because it uses a woven filter fabric designed for concrete pours.

650 RC Liquid Adhesive

For highway waterproofing, we suggest applying 650 RC Liquid Adhesive before installing a waterproofing membrane to concrete bridge decks or milled pavement surfaces.

As a solvent-based, asphaltic liquid adhesive primer that is applied below waterproofing membranes, the 650 RC Liquid Adhesive improves the bond between the membrane and the pavement. Not only is it simple to use but it also meets the requirements of ASTM D41.

Polyguard Products - The Best Option for Highway Waterproofing Membranes

Properly installed and maintained high-quality highway waterproofing pavement systems help protect against moisture, salt-infused water, and chemical damages, which is vital to managing repair and maintenance costs, extending the pavement's service life, and maintaining a safe infrastructure.

Contact our professionals at Polyguard for more information on highway waterproofing and road surface treatments!