Moisture, energy loss, and environmental exposure can quietly erode pipeline reliability if protective measures aren’t fully integrated. Insulation and external reinforcement systems work together to preserve performance in demanding environments. For many applications, selecting the right thermal pipe insulation is the first step in building a system that lasts.

Controlling Temperature Through Conduction Management

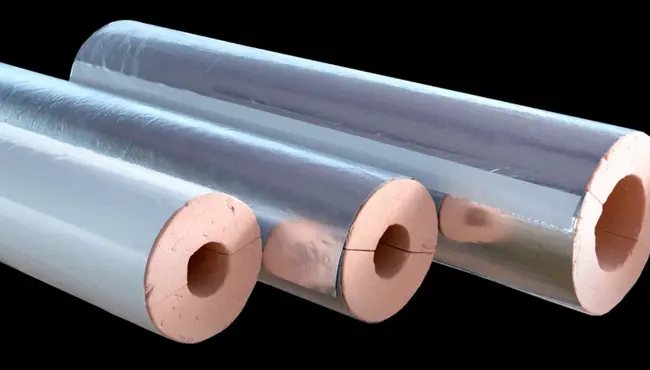

Without a thermal barrier, conductive and convective losses occur along the pipe surface, undermining temperature control. As fluids move through pipelines, they naturally lose or gain thermal energy unless properly insulated. The role of thermal pipe insulation is to interrupt that transfer, stabilizing internal temperatures and preserving energy.

Beyond efficiency, controlling conduction also improves safety and longevity. Without an insulating barrier, pipe surfaces can become dangerously hot or prone to condensation—either of which leads to mechanical or operational issues over time.

How Thickness and Material Type Shape System Performance

Thermal insulation requirements vary significantly based on pipe diameter, operating temperature, and exposure conditions. Choosing the correct combination of thickness and material type depends on a wide range of variables, including pipe diameter, fluid temperature, ambient environment, and energy retention requirements. Tools such as ASTM C680 support these decisions with data-backed thickness calculations.

Material options are selected based on their thermal conductivity, fire resistance, water permeability, and compressive strength. Fiberglass and mineral wool handle high heat well, while PIR and phenolic foams provide low conductivity with thinner profiles. Closed-cell elastomeric foams serve well in cold environments where vapor resistance is crucial.

Where Many Insulation Systems Fall Short

Even the best insulation can fail if it isn’t protected from the environment. Water ingress, sunlight exposure, and mechanical damage are frequent causes of degradation in both above- and below-grade installations. These external factors gradually wear down insulation layers, reducing their ability to retain heat and resist moisture.

That’s why long-term performance doesn’t depend on insulation alone. To preserve function, the full system must account for exposure threats and include components that shield the insulating layer over time.

Why Exposure Control Is Non-Negotiable in Harsh Environments

In underground or directional drilling scenarios, soil stress and surface abrasion can compromise both insulation and the pipe beneath. Similarly, chilled systems are vulnerable to vapor infiltration and freezing without a durable vapor barrier. These risks aren’t hypothetical—they show up frequently in post-installation failure assessments across industries.

Polyguard Products That Extend Insulation Lifespan

While Polyguard doesn’t manufacture insulation, its protective systems are designed to keep insulated assemblies intact under demanding conditions. RD-6® is one of the company’s core wrap solutions, offering a non-shielding protective layer reinforced with geotextile backing. It withstands soil pressure, resists water intrusion, and performs in high-temperature conditions. When used alongside thermal pipe insulation, it adds crucial external durability without compromising thermal continuity.

In chilled or cryogenic systems, Polyguard’s Insulrap™ 30 NG creates a flexible vapor barrier that holds its seal even after minor damage. It’s often applied over rigid foam insulation to prevent moisture intrusion and maintain consistent thermal performance in refrigeration and low-temp processing lines.

Defending Pipe Surfaces from Abrasion and Corrosion

For high-wear environments, the X-Wrap (formerly IRO) adds an abrasion-resistant layer over field joint coatings and insulation. It acts as a sacrificial barrier during installation, preserving the underlying system as it’s pulled through rough or uneven pathways. In systems with thermal cycling, RG-2400 ET—a non-drying corrosion inhibitor—offers an additional layer of defense beneath insulation, particularly on steel pipe surfaces.

Designing a Complete Assembly for Real-World Demands

Some projects require high flame resistance, low smoke emissions, or insulation materials that won’t deform under compression. Polyguard’s PolyPhen® phenolic foam line meets those demands while also working with its external wraps and gel-based corrosion solutions. When each element in the system is selected based on actual field conditions—not just catalog specs—performance improves dramatically.

Systems that include thermal pipe insulation work best when they’re reinforced with components that prevent degradation. Moisture, vibration, and mechanical wear can reduce insulation’s effectiveness if they’re not accounted for in the design phase. Polyguard’s protective offerings address these challenges without disrupting thermal continuity.

A Holistic View of Pipe Insulation Design

Too often, specifiers focus solely on R-values or thickness charts and overlook external variables like water intrusion or backfill impact. That approach invites premature failure.

Integrating thermal pipe insulation into a fully protected assembly is what makes long-term performance possible.

Polyguard products support this holistic view. They don’t compete with insulation materials—they make those materials viable long-term. From coatings that prevent corrosion under insulation to wraps that shield against soil damage, every layer works toward a single goal: stable, uninterrupted thermal control.

Improve System Reliability with Polyguard’s Thermal Protection Solutions

Thermal performance depends on both the insulation layer and the protective systems that surround it. Polyguard provides engineered wraps, coatings, and barriers that keep insulation effective across changing conditions. Contact us today for more information.