Corrosion is a constant threat to buried and submerged pipeline systems. Left unmanaged, it can compromise structural integrity, lead to hazardous leaks, and trigger major compliance failures. One of the most effective ways to mitigate these risks is through a well-engineered cathodic protection pipeline strategy.

Fundamentals of Electrochemical Protection for Steel Infrastructure

Cathodic protection works by redirecting electrical current away from steel pipeline surfaces, halting the oxidation process that causes metal loss. The pipeline is made cathodic—non-corroding—by applying a current from an external anode. This process slows or eliminates corrosion activity, extending the service life of buried assets under harsh soil or marine conditions.

There are two primary methods of delivering this current: galvanic systems and impressed current systems. Both operate on the same principle but differ in complexity, coverage range, and current control.

Two Core Systems for Pipeline Applications

Galvanic and impressed current systems each serve distinct roles in pipeline corrosion prevention. Their components, current delivery mechanisms, and field suitability differ based on soil conditions and network size.

Galvanic Anode Systems for Localized Coverage

Galvanic systems rely on sacrificial metals such as magnesium, zinc, or aluminum. These materials corrode instead of the steel, offering passive, self-regulating protection without the need for external power.

They are typically used on smaller pipelines or in environments where electrical infrastructure is unavailable. Their simplicity is an advantage, but coverage is limited by soil resistivity and pipeline surface area.

Impressed Current Systems for Wide-Area Distribution

Impressed current systems use a transformer-rectifier unit to deliver a controlled electrical current to an anode array. These systems support long-distance protection and are commonly installed in high-resistivity soils or across pipeline segments with varied backfill conditions.

Engineers can adjust voltage and current output over time, compensating for coating damage or soil chemistry changes. This flexibility makes them the preferred option for large-scale or mission-critical pipeline networks.

How Cathodic Protection Works in the Field

Cathodic protection on pipelines changes the electrochemical balance between metal and soil. Current flows from an anode through the surrounding environment into the pipeline. This shifts the pipeline’s potential below a defined threshold where corrosion reactions cease.

Field teams install reference electrodes and test stations to verify that the system maintains required polarization levels. NACE SP0169 outlines these voltage criteria and provides a standardized benchmark for effectiveness.

Engineering Design Factors That Shape System Performance

Pipeline cathodic protection design must begin with accurate field data. Engineers evaluate soil resistivity, pipe diameter, coating condition, length of pipeline, and surrounding environmental threats. These variables influence the total current required and the configuration of anode beds.

Deep anode beds are often used to reach stable moisture zones and deliver consistent current over long distances. Anode spacing, backfill resistivity, cable sizing, and rectifier output are selected to meet current demand without overpolarizing the structure.

Monitoring and Adjustment in Active Environments

Cathodic protection systems require continuous monitoring. Soil shifts, coating damage, and nearby construction can all alter current flow and weaken effectiveness. Operators use test stations and reference electrodes to verify system performance.

Field Surveys and Measurement Techniques

Surveys such as Close-Interval Potential Surveys (CIPS) and Direct Current Voltage Gradient (DCVG) testing provide detailed voltage maps along the pipeline. These diagnostic tools help operators locate weak spots and correct current deficiencies before corrosion begins.

Managing Electrical Interference and Shared Corridors

In dense utility corridors, current from one metallic structure can interfere with another. Alternating current from nearby power lines or rail systems often disrupts cathodic current paths. This interference can reverse the intended flow, making the pipeline anodic in some locations.

Mitigation tools such as decoupling devices, isolation joints, and grounding mats are engineered to control this risk. Regular interference testing is essential in congested areas or near energized installations.

Buried Pipeline Configurations and System Sensitivity

Pipeline configuration plays a role in current distribution. Bends, welds, and diameter transitions can affect how current flows through the structure. Engineers sometimes use supplemental bonding cables or auxiliary anodes at these features to maintain uniform protection.

Cathodic protection for natural gas pipelines also incorporates remote monitoring. These systems transmit data from rectifiers, test stations, and sensors to centralized control rooms, allowing for rapid adjustments.

Environmental Stressors and System Stability

Conditions like high-chloride soils, thermal gradients, and acidic groundwater introduce additional design demands. In these environments, coatings may degrade faster, and standard CP systems may struggle to maintain adequate polarization.

In such cases, supplemental barriers—such as protective membranes or chemically resistant coatings—can reinforce long-term protection. These materials must maintain bond strength, water resistance, and thermal stability under field stresses.

Complementary Barriers for Harsh Site Conditions

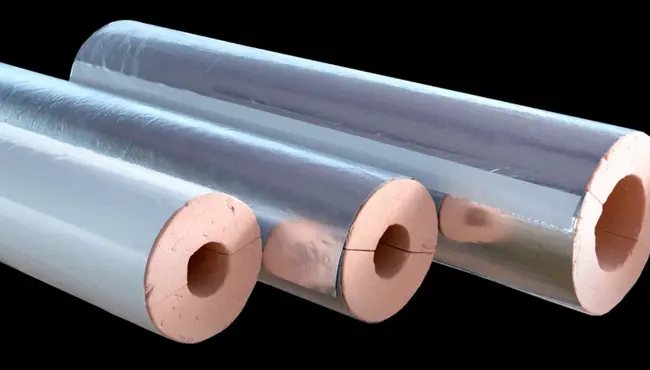

High-performance wrap coatings and membrane-based barriers are often specified in conjunction with cathodic protection in demanding applications. These materials provide continuity in coverage across weld zones, bends, and movement-prone areas.

Products that resist thermal cycling, water vapor intrusion, and mechanical abrasion enhance CP effectiveness by shielding areas that are vulnerable to coating failure. They also reduce current demand by preserving a more intact barrier system.

Integrated Lifecycle Approach to Pipeline Corrosion Defense

Cathodic protection of underground pipelines is not a standalone fix. It requires planning, system customization, active monitoring, and eventual reevaluation. All components—from rectifiers and anodes to data loggers and coatings—must work in concert.

Effective designs prioritize real-world conditions over theoretical load models. In-field testing, local soil analysis, and operational history all contribute to system longevity and regulatory success.

Specialized Coatings from Polyguard That Enhance Protection

RD‑6® HT Coating System uses a geotextile‑backed, non‑shielding wrap designed for buried or submerged line pipe. It maintains cathodic current flow even if coating experiences minor disbondment. The composite wrap resists temperatures up to 190 °F (88 °C), withstands soil stress, and installs using Polyguard’s Wrapster™ equipment.

RD‑6® Coating System provides corrosion resistance for new construction and rehabilitation projects. Its tightly woven polypropylene backing allows cathodic current through damaged zones. It also includes SP‑6™ outerwrap for added mechanical protection on pipelines over 4 inches in diameter.

Extend Pipeline Integrity with Polyguard's Protective Technologies

Proven protective materials reinforce cathodic protection pipeline systems. This approach lowers corrosion failure rates and extends service life in buried environments.

Contact us today for more information.