Pipeline systems are vulnerable to a form of internal degradation that’s often overlooked during routine inspections. Microbial activity inside the pipe can lead to unexpected corrosion, reduced service life, and operational disruptions. Managing microbiological corrosion in pipelines, also known as MIC, requires early intervention, targeted materials, and long-term planning.

What Triggers Microbial Corrosion Inside Pipeline Systems

Bacteria that form biofilms thrive in dark, moist, and low-flow environments. When these organisms settle on interior surfaces, they generate corrosive byproducts that disrupt the metal’s passive layer and begin a cycle of localized degradation. Unlike chemical corrosion, the biological process often unfolds unevenly and escapes early detection.

Once these colonies become established, they create an insulated environment that blocks treatment chemicals and makes mechanical removal far less effective. Even with cleaning tools like pigs or frequent flushing, embedded organisms can reappear in the same location due to surface imperfections or stagnation zones.

How MIC Damage Avoids Detection Until It’s Too Late

Structural weakening from microbial activity often hides under protective layers or sediment buildup. Operators might see changes in pressure or flow rate, but the biological source of degradation is rarely apparent without a more detailed inspection protocol. Relying solely on ultrasonic tools or corrosion coupons won’t confirm microbial involvement.

Advanced testing such as surface swabbing, intact cell counts, and microbial sequencing provide deeper insight into colony formation and risk zones. These diagnostic approaches are essential for confirming that material loss stems from biological—not chemical—origin and guiding treatment responses before serious failure occurs.

Conditions That Encourage Persistent Microbial Activity

1. Low Flow or Dead-End Sections

Areas with minimal fluid movement are highly susceptible to microbial colonization. Water and nutrients settle in these zones, offering an ideal home for biofilm development and acid production.

2. Subsurface and Subsea Environments

Buried infrastructure lacks access for frequent inspection or manual treatment. Once microbes infiltrate small surface defects or coating failures, they can exploit anaerobic conditions to accelerate metal loss without being noticed.

3. Construction Material Vulnerabilities

Not every pipeline coating is formulated to resist microbial adhesion. High-performance polymers that perform well in chemical resistance may still allow biological degradation if surface porosity or application errors exist.

Why MIC Accelerates So Rapidly Once It Begins

The threat of microbiological corrosion in pipelines escalates quickly after colonization. Acid-producing bacteria and sulfate reducers alter pH and generate localized reactions that undermine steel from beneath the surface. These reactions often occur in tiny pockets under scale or insulation, escaping detection until the damage becomes structural.

Biofilms also create oxygen differentials and galvanic zones, amplifying metal loss at seams and joints. Standard maintenance routines may clean the visible pipe wall but leave core microbial zones untouched, leading to recurrence even after apparent remediation.

Smarter Detection Tools Now Guide Earlier Action

Molecular diagnostics and microbial profiling now allow operators to track colony growth before pitting or cracking begins. By mapping microbial presence alongside flow dynamics and temperature, predictive models help locate emerging problem areas and inform preventive action plans.

ATP assays, gene sequencing, and high-resolution mapping now make it possible to design intervention schedules that prevent biofilm establishment. These tools mark a shift from reactive repair to proactive asset management, where microbial risk is quantified before failure, not after.

Material Selection Plays a Key Role in MIC Prevention

Surface coatings are no longer just protective—they must actively resist microbial adhesion and infiltration. Certain materials, while chemically robust, may still develop underfilm corrosion when microbes find their way through pinholes or scratches. Once beneath the barrier, bacteria can operate anaerobically, causing deep pitting without surface warning signs.

Engineered barrier systems that combine high adhesion, chemical resistance, and microbial repellence deliver longer-lasting protection—especially in submerged or buried conditions where reapplication is complex. Durability is no longer optional; it must be built into the material from the start.

Consequences of MIC Extend Beyond the Pipe Wall

Microbial degradation does more than damage infrastructure. In potable water systems, it introduces contamination and biofouling risks. In oil and gas lines, corrosion byproducts interact with flow materials, generating sludge, clogs, or abrasive black powder that interferes with valves and instrumentation.

These secondary effects increase maintenance demands and complicate operations far from the original microbial site. Addressing these threats early with the right materials and inspection protocols is not only cheaper—it’s safer for the entire system.

The High Cost of MIC: Downtime, Damage, and Long-Term Risk

The financial implications of microbiological corrosion in pipelines extend far beyond material replacement.

- The cascading costs of MIC include emergency repairs, compliance penalties, and site remediation—often triggered by failures that go undetected until critical.

- In the U.S. oil and gas industry alone, microbiologically influenced corrosion is estimated to contribute over $2 billion annually to corrosion-related costs.

This highlights how preventive measures can reduce both operational and financial pressure. In water treatment facilities, chemical plants, and energy networks, even minor breaches can lead to widespread operational disruption. When contamination or service interruptions occur, the fallout includes higher insurance costs, reputational risk, and potential legal exposure..

A Risk Management Approach That Looks Beyond the Surface

Operators who treat microbiological corrosion in pipelines as a structural or chemical issue alone will miss the biological drivers behind repeat failures. A comprehensive response integrates microbial diagnostics, flow modeling, intelligent cleaning, and long-term material science.

Planning for MIC mitigation at the design stage reduces lifetime costs and minimizes the chance of system-wide failure. Solutions that block microbial attachment and resist acidic degradation can prevent decades of recurring damage.

Polyguard Solutions Target the Root Causes of MIC

As industries confront the rising cost of MIC-related failures, Polyguard provides durable solutions designed to reduce long-term financial exposure and protect critical infrastructure investments. Polyguard’s engineered protection systems are built for environments where microbial degradation poses a continual threat. With a focus on complete barrier integrity and resistance to underfilm infiltration, these coatings help asset owners minimize maintenance intervals and avoid unexpected downtime.

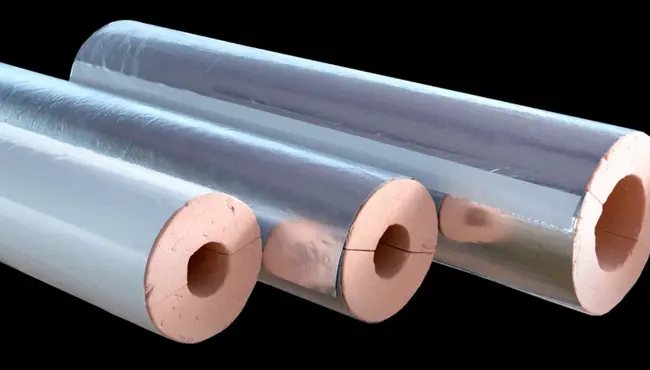

RD-6® Coating System

Among Polyguard’s most proven options is the RD-6® Coating System, a non-shielding wrap that resists disbondment and prevents microbial attack beneath the surface. It maintains compatibility with cathodic protection systems, even if mechanical damage occurs, making it highly effective for buried and submerged pipelines.

NHT-5600

For high-temperature or high-stress applications, NHT-5600 delivers robust corrosion resistance while tolerating aggressive site conditions. Its chemical formulation and adhesion performance make it ideal for critical pipelines where both microbial threats and thermal cycling are present.

When paired with microbial diagnostics and data-informed maintenance strategies, these systems protect infrastructure investments from biologically driven decay. The result is higher performance with lower long-term cost—and a system that stays protected where others degrade.

Build Long-Term Resilience with Polyguard’s MIC Protection

Polyguard provides targeted solutions that help prevent microbiological corrosion in pipelines before damage begins. Our materials support data-driven maintenance strategies and long-term reliability for critical assets. Contact us today for more information.